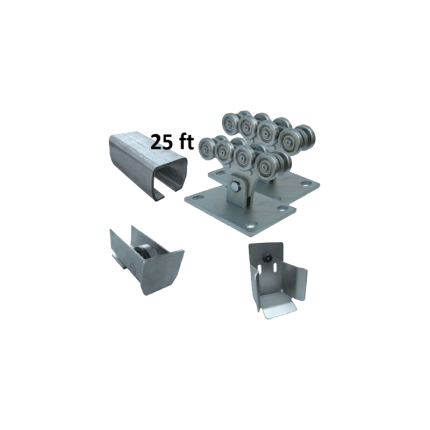

hardware

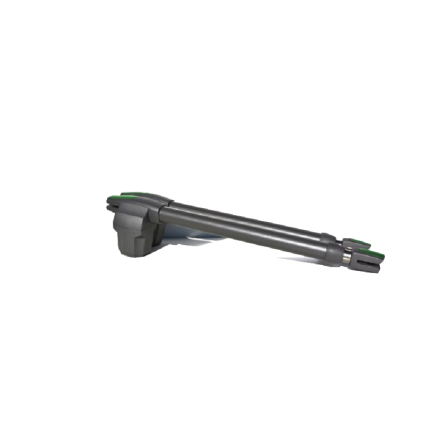

Swing gate opener -KeyAutomation REP2224

Ship or pick up from our office.

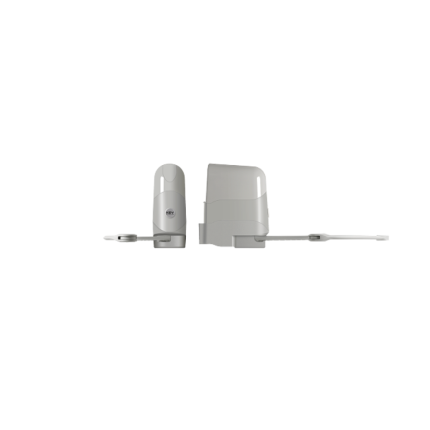

PRODUCT SHEET PDFGate/Door opener key selector -KeyAutomation EGS101

Driveway swing gate – Deer design – 12 ft

- Ship or pick up from our showroom at #100, 11538 132A Street, Surrey, BC.

- Royal Gate Deer Style Dual Swing Driveway Gate

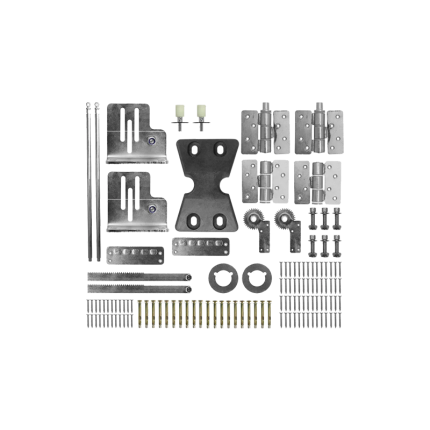

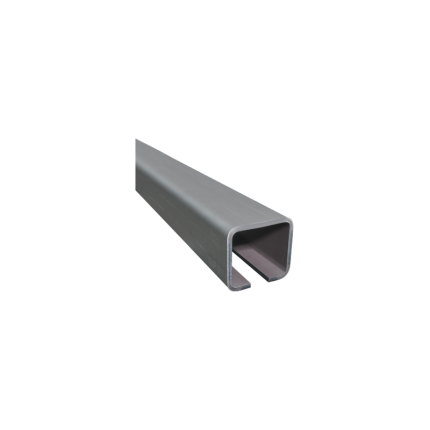

- Gate Package Includes: 2 x driveway gate panel, 2 x steel gate posts (8′ H by 4″ x 4″ each), 4 x Heavy duty adjustable steel hinges

- Material: Hot Dip Galvanized steel gate with a black powder paint coating

- Gate Dimensions: 12′ W x 6′ H.

- No hidden fees