gate operator

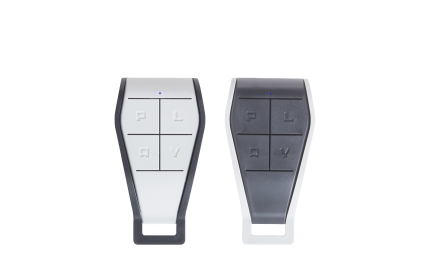

Gate Opener Remote Control -C4

Ship or pick up from our office.

Gate Opener Remote Control -C4

*433 MHz

*2-4 Buttons

*More than 10 different designs

Key features and functions of a gate opener remote control:

-

Remote Operation:Enables opening and closing the gate from a distance, typically within a certain range (e.g., 100 feet).

-

Radio Signal Transmission:Emits a radio signal to the gate's receiver unit, initiating the gate's movement.

-

Compatibility:Most remotes are compatible with specific gate openers and require the same frequency to function.

-

Programming:Can be programmed with the gate's receiver unit, often involving a "learn" or "program" button on the gate opener.

-

Multiple Remotes:Many gate openers can be paired with multiple remotes, allowing multiple users to control the gate.

-

Universal Remotes:Some universal remotes can be programmed to work with different gate opener brands, as long as they are compatible.

-

Safety Features:Some gate openers incorporate safety features like sensors that detect obstructions and reverse the gate's movement.

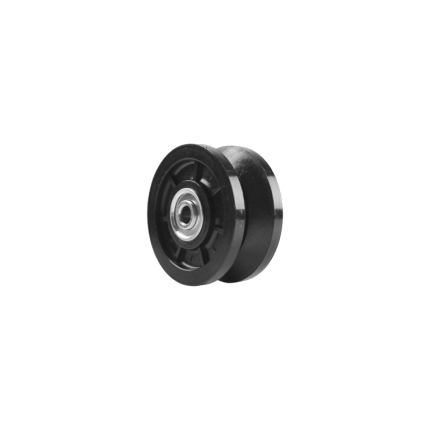

Support Roller

Ship or pick up from our office.

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.

Sliding gate V-Groove nylon wheels -SLGWN778MLB

Gate operator control board fuse

Ship or pick up from our office.

Gate operator control board fuse

A gate operator control board fuse is a critical safety component found on the circuit board of an automatic gate system. Its primary function is to protect the electrical components of the gate operator from damage caused by excessive current, such as a short circuit or an overload. Essentially, it acts as a sacrificial link in the electrical circuit. If the current flowing through the circuit exceeds a predetermined safe limit, the thin metal wire or strip inside the fuse melts and breaks the circuit. This prevents the surge of electricity from reaching and damaging more expensive and vital components on the control board or in the motor. Types and Characteristics Gate operator control board fuses come in various amperage ratings, typically ranging from 0.2 to 15 amps, depending on the specific gate operator model and its power requirements. Some common characteristics include:- Slow-Blow/Time-Delay Fuses: Many gate operators use "slow-blow" or "time-delay" fuses. These fuses are designed to tolerate brief, temporary current surges that often occur when motors start up without immediately blowing. They only interrupt the circuit if the overload persists for a longer duration.

- Physical Form: They can be found in various physical forms, including glass tube fuses (common in older models), blade-style automotive fuses, or sometimes as surface-mount fuses directly on the printed circuit board.

- Short Circuit: A direct path for current to flow, bypassing the normal resistance, causing a sudden and large surge.

- Overload: The gate motor or another component drawing more current than it's designed for, perhaps due to mechanical obstruction, a faulty motor, or issues with the gate's movement (e.g., binding hinges, gate dragging on the ground).

- Component Failure: A faulty component on the control board or within the gate operator system itself can cause an abnormal current draw, leading the fuse to blow.

- Power Surges: External power surges from the main electrical supply or lightning strikes can also cause fuses to blow.

- Disconnect Power: Always disconnect all power to the gate operator before attempting any inspection or repair. This includes both AC power and any battery backup systems.

- Locate the Fuse: The fuse is typically located directly on the main control board, often in a small holder or a clear cover. Refer to your gate operator's manual for its exact location.

- Inspect the Fuse:

- For glass tube fuses, you can often visually inspect the wire inside; if it's broken or discolored, the fuse is blown.

- For blade-style fuses, there might be a visible break in the metal strip, or you can use a multimeter set to continuity mode. A blown fuse will show no continuity.

- Replace the Fuse: If the fuse is blown, replace it with a new fuse of the exact same amperage (ampere) and voltage rating. Using a fuse with a higher rating can lead to damage to the control board or other components, as it won't blow when it should. Using a lower rating may cause the fuse to blow unnecessarily.

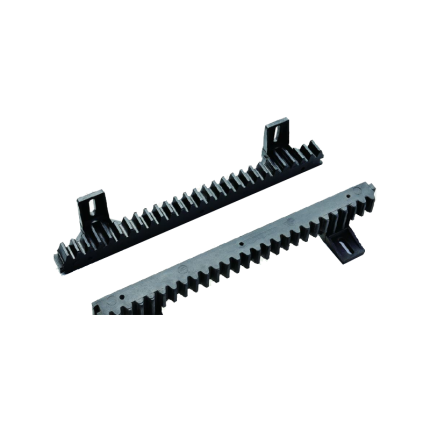

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

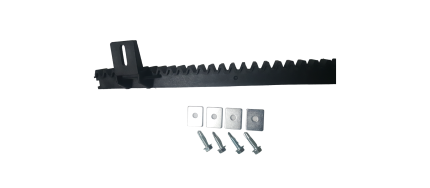

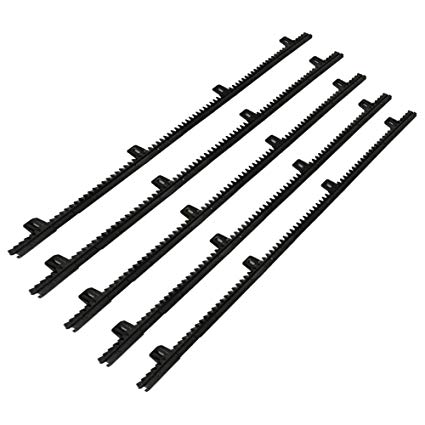

Sliding gate operator gear rack -SLGR41

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR41

*4 Holes *Length: 1018 mmSafety sensor – V2 Sensiva XS

Ship or pick up from our office.

Safety sensor - V2 Sensiva XS

*NO/NC *AC 12-24 V / DC 21-36 V *Receiving Range: 20 Meters *IP 44Discover the SENSIVA V2 Safety Sensor

The SENSIVA V2 photocells are innovative safety devices designed to provide optimal protection for your automated gates and garage doors. Using an infrared beam, they efficiently detect obstacles to stop or reverse the gate's movement, thus preventing any risk of collision or accident. With their compact design and advanced synchronization technology, they easily integrate into any type of installation, offering a reliable and durable solution for both indoor and outdoor environments.Technical Specifications

- Power Supply: 12-24 V AC / 12-36 V DC

- Range: Up to 20 meters for the SENSIVA-XS model, and 25 meters for the standard SENSIVA model

- Protection Rating: IP54, resistant to dust and water splashes

- Orientation: Head adjustable horizontally up to 180° and vertically up to 30° (SENSIVA only)

- Dimensions: 84 x 29 x 24 mm (SENSIVA-XS) and 86 x 41 x 38 mm (SENSIVA)

- Operating Temperature: -20°C to +60°C

- Manual: Digital (QR Code) with simple and quick installation

Key Features

- Maximum Safety: Accurate and reliable obstacle detection to prevent accidents.

- Synchronization: Advanced technology to prevent interference between multiple pairs of photocells.

- Versatile Installation: Compatible with wall or post installations (SENSIVA-XS).

- Weather Resistance: IP54 rating and optimal operation under extreme conditions.

- Adjustable Orientation: Easy configuration to fit all installations (SENSIVA model).

Why Choose the SENSIVA V2 Photocells?

- Reliability: Ensure the safety of your automated gates with precise and effective obstacle detection.

- Modern Technology: Anti-interference synchronization and protection against sunlight.

- Durability: Resistant to wear and weather conditions thanks to robust design and high-quality materials.

- Flexibility: Two models to meet all needs: compact (SENSIVA-XS) or standard (SENSIVA).

Original Gate Opener Remote Control

Ship or pick up from our office.

Original Gate Opener Remote Control

*433 MHz *2-4 Buttons *(More than 10 different designs)A gate opener remote is a handheld device that allows you to remotely open and close an automatic gate.

It sends a radio signal to a receiver connected to the gate's motor, triggering the gate to move. These remotes are a convenient way to control access to properties, especially when entering or exiting with a vehicle.

Here's a more detailed explanation:

-

Function:The remote transmits a radio signal to a receiver unit connected to the gate opener motor.

-

Convenience:They eliminate the need to manually open or close the gate, providing convenience and security.

-

Compatibility:Remotes must be compatible with the gate opener's frequency and coding system.

-

Types:There are various types of remotes, including single-button (for basic open/close) and multi-button (for more complex functions like stopping or partially opening the gate).

-

Programming:Remotes need to be programmed to work with the specific gate opener.

-

Frequency:Most gate openers use 433.92 MHz frequency, but some older systems might use different frequencies.

-

Range:The range of the remote can vary depending on obstructions like trees or buildings.

Programmer module -Key Automation KUBEPRO

Ship or pick up from our office.

PRODUCT SHEET PDFProgrammer module -Key Automation KUBEPRO

*KUBEPRO - Installer Version *Smartphone programming for 14A and HALO control boardsThe Key Automation KUBEPRO is a programmer module that allows professional installers to configure and manage Key Automation gate and door operators using a smartphone.

It connects via Bluetooth to the installer's smartphone and allows them to adjust parameters, set up the gate opener, and manage other aspects of the automation system.

The KUBE PRO also includes the KEY CLOUD service for data viewing, backup, team management, and maintenance scheduling.

Here's a more detailed breakdown:

-

Purpose:The KUBEPRO is designed for professional installers to configure and manage Key Automation gate and door operators.

-

Functionality:It allows installers to adjust various parameters, set up the gate opener, and manage other settings directly from their smartphone.

-

Connectivity:It connects to the gate operator's control board and uses Bluetooth to communicate with the installer's smartphone.

-

Smartphone App:An app, specifically designed for professional installers, is used to interact with the KUBEPRO module.

-

KEY CLOUD:The KUBE PRO module includes KEY CLOUD, a cloud-based service for storing data, managing teams, and scheduling maintenance.

-

Accessibility:The KUBE PRO module is restricted to users with a Key Automation account, ensuring proper authorization and usage.

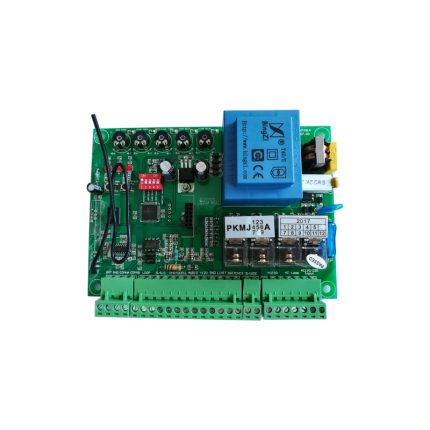

Universal sliding gate operator control board SLRG24

Ship or pick up from our office.

Universal sliding gate operator control board SLRG24

The Universal Sliding Gate Operator Control Board SLRG24 is the "brain" of an automatic sliding gate system. It's designed to be a versatile replacement or core component for various DC-powered sliding gate operators, meaning it can control a wide range of motors and integrate with different accessories. Here's a detailed look at its features and significance: Core Function of a Control Board: The control board is the central electronic unit that:- Receives Signals: Interprets commands from remote controls, keypads, safety sensors (photocells, shock sensors, loop detectors), intercom systems, and other access control devices.

- Processes Logic: Decides what action the gate should take based on the received signals and its programmed settings (e.g., open fully, partially open for pedestrian, close, stop, reverse due to obstruction).

- Activates Motor: Sends the appropriate electrical signals to the gate motor to start, stop, or reverse its movement.

- Manages Accessories: Controls the power and operation of connected safety and convenience accessories like flashing lights, electric locks, and alarm outputs.

- Universal Compatibility: This is its defining characteristic.

- DC Motor Compatibility: It's designed to work with both DC 12V and DC 24V motors. This flexibility is crucial as many sliding gate operators use one of these DC voltages. It's important to note that it is NOT compatible with AC (Alternating Current) motors (like 110V or 220V AC motors).

- Limit Switch Flexibility: It can work with both spring-type mechanical limit switches and magnetic limit switches. This is a significant advantage for a universal board, as it means it can be used with a wider range of existing gate operators.

- Input Power: The board itself typically requires an AC 24V input power. This means it likely has an internal transformer or is designed to be powered by an external AC 24V transformer.

- Full Programmability: Offers a wide range of adjustable parameters, allowing customization of gate operation to suit specific needs:

- Gate Speed: Adjustment of how fast the gate opens and closes.

- Opening/Closing Times: Setting precise durations for gate cycles.

- Automatic Closing Time: Programming a delay before the gate automatically closes after opening (e.g., 15, 30, 45 seconds, or up to 3 minutes).

- Safety Settings: Integration and management of safety sensors (photocells, obstacle detection sensitivity).

- Pedestrian Mode: Ability to set a partial opening for pedestrian access.

- Party Mode: Often allows for temporary cancellation of auto-close for periods when many visitors are expected.

- Remote Control Capability:

- Features an integrated radio receiver, typically operating at 433.92MHz with rolling code technology. Rolling code prevents unauthorized cloning of remote controls, enhancing security.

- Supports multiple remote controls (e.g., up to 20 or more), making it suitable for larger families or multi-user environments.

- Accessory Output Power: Provides DC 24V accessory output power (e.g., 200mA max) to power various external devices:

- Safety Sensors (Photocells): Connects to and powers safety beams.

- Warning Flash Lights: Powers a flashing beacon that activates when the gate is in motion.

- Keypads/Intercom Systems: Provides power and input connections for wired access control devices.

- Electric Locks: Can manage the operation of an electric lock for added security.

- Safety Mechanisms:

- Obstacle Detection: Uses current sensing or other methods to detect if the gate encounters an obstruction during movement. Upon detection, it will typically stop or reverse the gate for safety.

- Automatic Stop Function: Ensures the gate stops precisely at its programmed limits.

- Short Circuit Protection: Often includes protection for output circuits (e.g., lock output) to prevent damage from wiring faults.

- Solar System Input: The mention of "Input Solar system" suggests it's designed to be compatible with or directly connect to solar charging systems for off-grid gate installations, making it suitable for rural properties or areas without easy access to AC power.

- Installation and Durability:

- Designed for relatively easy installation.

- Built with robust components for long-lasting performance in various weather conditions, though it usually requires housing in a waterproof box (often included in a kit).

- Features an automatic power-off memory function, retaining settings after a power outage.

- Replacing a Faulty Board: If an existing 12V or 24V DC sliding gate operator has a non-functional control board, the SLRG24 could be a suitable and cost-effective replacement, reducing the need to replace the entire gate motor.

- New Custom Gate Systems: It provides a flexible "brain" for custom-built sliding gate systems where the motor and other components are chosen separately.

- Solar-Powered Gates: Its solar input capability is a definite advantage for properties in Surrey or surrounding areas that might prefer or require solar power for their gate.

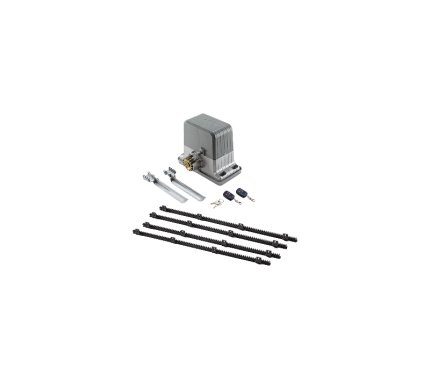

Sliding gate opener -Royalgate RGSL1.8TO

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL1.8TO

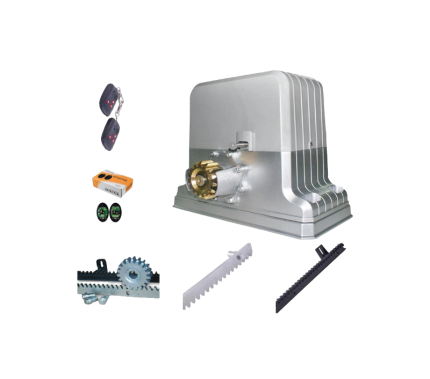

Sliding gate opener -VDS Simply SL110

Ship or pick up from our office.

Product Sheet PDF

Italian-made with the highest quality materials and state-of-the-art technology.

Opening gates weighing up to 1300 lbs effortlessly with this gear rack-driven sliding gate opener.

It is designed with a 110V AC motor which provides exceptional torque and its continuous operation makes it ideal for most applications.

- Opens gates weighing up to 1300 lb (600 KG)

- Pre-wired and Easy programming - Watch the installation tutorial on our YouTube channel

- Solid cast iron and steel gears

- Control unit box with an air-stop seal against moisture and insects

- Lithium grease lubricated mechanical parts against corrosion, oxidation, and rust

- Very quiet operation

- High-performance electric motor

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated.