driveway gates

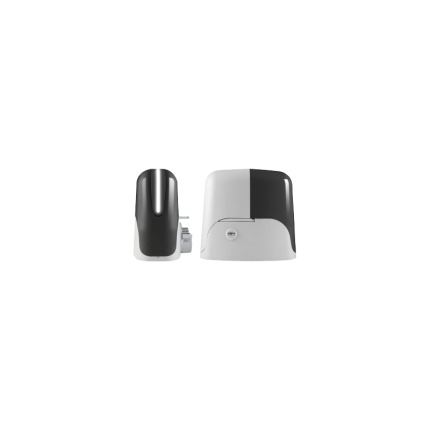

Sliding gate opener –Key Automation SUN11024

Ship or pick up from our office.

Product Sheet PDFSliding gate opener –Key Automation SUN11024

High-quality Italian-made with state-of-the-art technology and design. Open gates weighing up to 1100 KG effortlessly with this gear rack-driven sliding gate opener. It is designed with a 24V DC motor, which provides exceptional torque, and its continuous operation makes it ideal for most applications. A 13 ft nylon gear rack track is included in the kit, and if your gates are more than 13 ft in length, then you can opt for an extra rack.- Opens gates weighing up to 1100 kg

- Easy to install and program

- Get the desired torque and tension by adjusting the parameters using the KUBE PRO and PROGRAMMING MODULE

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate opener –KeyAutomation TURBO4224

Ship or pick up from our office.

Product Sheet PDFSliding gate opener –KeyAutomation TURBO4224

High-quality Italian-made with state-of-the-art technology and design. Sliding gate opener Key Automation TURBO4224 Open gates weighing up to 400 KG effortlessly with this gear rack-driven sliding gate opener. It is designed with a 24V DC motor, which provides exceptional torque, and its continuous operation makes it ideal for most applications. The kit includes a 13 ft nylon gear rack track, and if your gates are more than 13 ft in length, you can opt for an extra rack.- Opens gates weighing up to 400 kg

- Easy to install and programming

- Get the desired torque and tension by adjusting the parameters on the control board

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote controls, radio receivers, and safety sensors can also be integrated

Sliding gate opener –Royalgate RGSL0.8TND

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL0.8TND

Sliding gate operator chain

Ship or pick up from our office.

Sliding gate operator chain

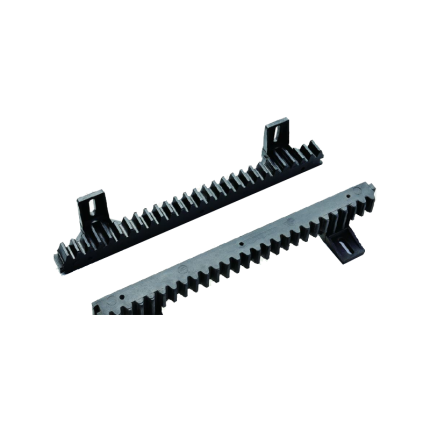

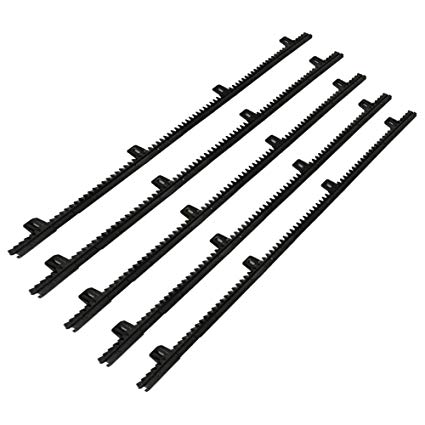

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

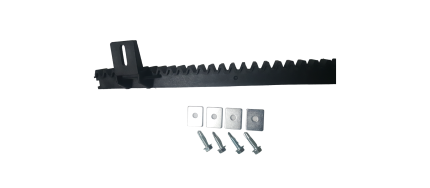

Sliding gate operator gear rack -SLGR41

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR41

*4 Holes *Length: 1018 mmSliding gate operator main control board – Key Automation

Ship or pick up from our office.

Sliding gate operator main control board – Key Automation

The main control board for a Key Automation sliding gate operator, like the SUN7224 or SUN11024, is the central processing unit that manages the gate's movement, safety features, and other functionalities.

It receives signals from remote controls, keypads, or sensors, and then directs the motor to open or close the gate accordingly.

Here's a more detailed explanation:

-

Core Function:The control board acts as the "brain" of the gate system, interpreting signals and controlling the motor.

-

Input:It receives signals from various input devices, such as remote controls, keypads, or safety sensors.

-

Output:It sends commands to the motor to start, stop, reverse, or adjust its speed based on the input received.

-

Safety Features:Many control boards include safety features like obstacle detection, which can automatically stop or reverse the gate if it encounters an obstruction.

-

Programming and Diagnostics:Some control boards offer programming capabilities and diagnostic displays to simplify setup and troubleshooting.

-

D-Track Technology:Some Key Automation models, like the Deimos, utilize D-Track technology for precise torque management and impact detection.

-

Power Supply:Control boards typically operate on a specific voltage (e.g., 24V DC or 110V AC).

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.

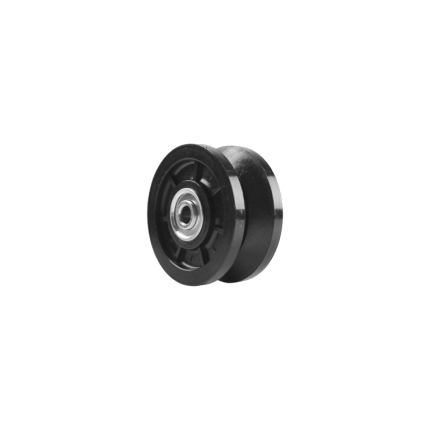

Sliding gate V-Groove nylon wheels -SLGWN778MLB

Ship or pick up from our office.

Sliding gate V-Groove nylon wheels -SLGWN778MLB

*Double bearing *Max 250 Kg *4" Diameter x 1-3/4" Width (Heavy-duty bolts, nuts, and washers are included)Sliding gate V-Groove nylon wheels -SLGWNS250

Ship or pick up from our office.

Sliding gate V-Groove nylon wheels -SLGWNS250

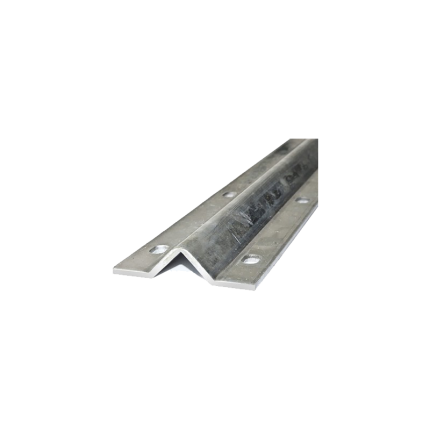

*Double bearing *Max 250 Kg *98 mm Diameter (4") x 44 mm Width (1-3/4") (Heavy-duty bolts, nuts, and washers are included)Sliding Gate V-Track

Ship or pick up from our office.

Sliding Gate V-Track

NOTE: For 25 ft sliding gate V-Track, please do not make an online order.Because of the limit of the shipping length and weight, we have to cut the full length of the product (25') to 2 x (12'-6") for pick-up from our store OR 4 x (6'-3") to send by Canada Post.

If your order requires cutting services, additional costs will apply.

To create an order for sliding gate V-Track, please send your request with the shipping address, postal code, and the length of your inquiry in the note. You will receive a quotation with the shipping costs within a maximum of one business day. A sliding gate V-track is a specific type of ground track that a sliding gate rolls on, utilizing wheels with a complementary V-shaped groove. This system is one of the most common ways to implement a sliding driveway gate, especially for residential and light commercial applications. Here's a breakdown: Purpose: The sliding gate V-track as the linear guide and support for the entire sliding gate. It ensures that the gate moves in a straight line, smoothly, and without wobbling or derailing as it opens and closes. It's an integral part of a "rolling gate" system, where the gate literally rolls on the ground. Key Characteristics and Components:- V-Shape Profile: The most defining feature. The track has an inverted V-shape or a 90-degree angle (like an angle iron) with a slightly rounded top. This V-shape mates perfectly with the V-groove wheels attached to the bottom of the gate.

- Materials:

- Galvanized Steel (Most Common): Highly durable, strong, and resistant to corrosion due to the galvanization process. It can handle heavy gates and high traffic volumes. Sections are typically joined together to form the required length.

- Aluminum: Lighter weight and excellent corrosion resistance. Often used for lighter gates or in environments where rust is a major concern (like coastal areas).

- Installation:

- Bolt-Down: The V-track is typically designed to be bolted securely to a concrete driveway or foundation. It has pre-drilled holes for anchor bolts. This allows for easier installation on existing concrete and simpler replacement if a section gets damaged.

- Embeddable (Less Common for DIY): Some V-tracks are designed to be embedded directly into wet concrete during construction.

- Level and Straight: Crucially, the V-track must be installed perfectly level and straight along the entire travel path of the gate to ensure smooth and consistent operation. Any dips, humps, or curves will cause issues with the gate's movement and can put undue strain on the gate operator and wheels.

- Lengths: Sliding gate V-tracks are sold in sections (e.g., 6 feet, 10 feet, 2.4 meters, 3 meters). Multiple sections are joined together using connection pins or by welding to achieve the total required length, which should be at least twice the width of the gate opening to allow the gate to fully retract.

- Complementary Hardware:

- V-Groove Wheels: These are essential and roll directly on top of the V-track. As discussed previously, they have a V-shaped groove that fits snugly into the track.

- Guide Rollers/Posts: Used at the top of the gate to keep it upright and prevent tipping.

- Gate Stops: Installed at the ends of the track to prevent the gate from over-traveling.

- Stability: The sliding gate V-track V-groove design provides excellent lateral stability, keeping the gate aligned and preventing it from wobbling.

- Load Capacity: Due to the direct ground support and robust V-track/wheel combination, these systems can handle very heavy and long gates.

- Simple Mechanical Principle: The system is straightforward, making it reliable.

- Debris Accumulation: The main drawback is that the V-track, being on the ground, is susceptible to collecting dirt, leaves, gravel, snow, and ice. This debris can obstruct the gate's movement, cause wear on the wheels, and may even lead to derailment or damage to the gate opener. Regular cleaning of the track is essential, especially during winter months in Canada.

- Driveway Disruption: Installing a sliding gate V-track requires modifying the driveway surface, often by bolting it down or embedding it in concrete, which creates a slight raised profile.

- Water Drainage: Proper drainage around the track is important to prevent water pooling.

Sliding gate, Full Privacy, 12 ft

Pick up from our showroom at #100, 11538 132A Street, Surrey, BC.

Sliding gate, Full Privacy, 12 ft

- Aluminum Full Privacy Sliding Gate

- Sliding Gate Package Includes: 1 x driveway gate panel, 2 x steel gate posts (8' H by 4" x 4" each), Rollers, Wheels, V-tracks

- Material: Aluminum Tube Framing, Aluminum privacy panels with a black powder paint coating

- Sliding Gate Dimensions: 12' W x 6' H.

- No hidden fees

A sliding gate is a type of gate that opens and closes by moving horizontally along a track, typically along a fence line.

Unlike swing gates, which rotate on hinges, sliding gates save space, making them ideal for narrow driveways or areas with limited space. They are commonly used in residential, commercial, and industrial settings for security and access control.

Here's a more detailed explanation:

How it works:

-

Track and Wheels:Sliding gates typically move along a track, either embedded in the ground or mounted along the fence line. They are supported by wheels or rollers that run along the track.

-

Mechanism:The gate is usually opened and closed by a motor and gear system that engages with a toothed rack on the gate, causing it to slide.

-

Space Saving:The horizontal movement allows sliding gates to operate in areas where swing gates wouldn't be feasible due to space constraints.

-

Security:Sliding gates offer a robust security solution, especially when combined with access control systems.

-

Types:Common types include traditional sliding gates, which use a track, and cantilever gates, which don't require a ground track and are supported by a counterbalance system.

-

Benefits:They are known for their space-saving design, ease of installation (especially cantilever gates), and minimal maintenance.