driveway gates

Relay Mini PCB 5-Pin 10A

RFID Tag Access Control

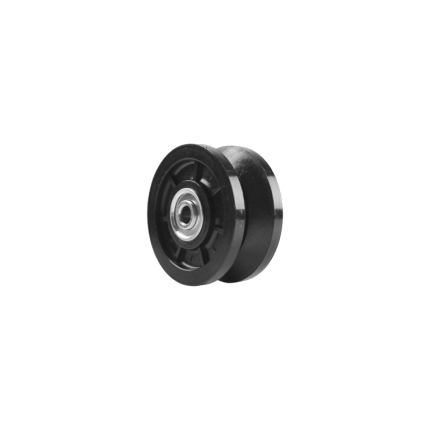

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.

UHF Label

Card Holder

UHF Tag

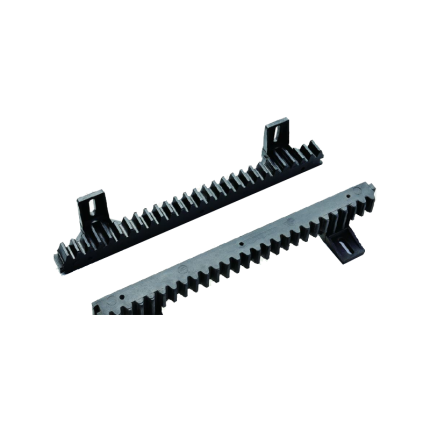

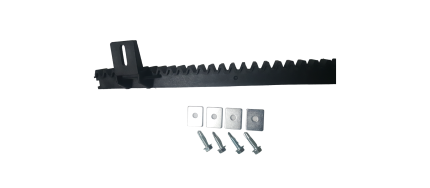

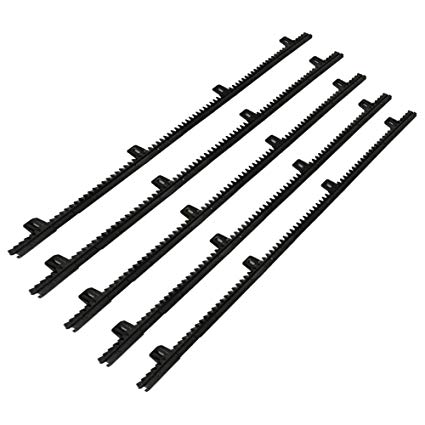

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.