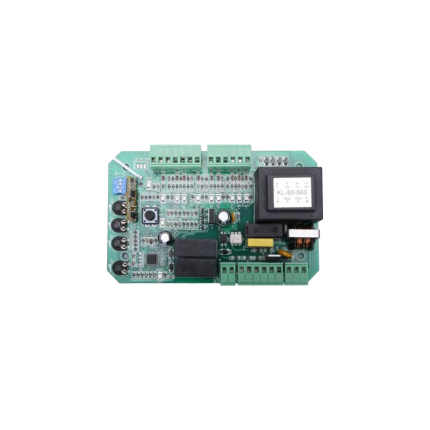

board

Gate operator control board fuse

Ship or pick up from our office.

Gate operator control board fuse

A gate operator control board fuse is a critical safety component found on the circuit board of an automatic gate system. Its primary function is to protect the electrical components of the gate operator from damage caused by excessive current, such as a short circuit or an overload. Essentially, it acts as a sacrificial link in the electrical circuit. If the current flowing through the circuit exceeds a predetermined safe limit, the thin metal wire or strip inside the fuse melts and breaks the circuit. This prevents the surge of electricity from reaching and damaging more expensive and vital components on the control board or in the motor. Types and Characteristics Gate operator control board fuses come in various amperage ratings, typically ranging from 0.2 to 15 amps, depending on the specific gate operator model and its power requirements. Some common characteristics include:- Slow-Blow/Time-Delay Fuses: Many gate operators use "slow-blow" or "time-delay" fuses. These fuses are designed to tolerate brief, temporary current surges that often occur when motors start up without immediately blowing. They only interrupt the circuit if the overload persists for a longer duration.

- Physical Form: They can be found in various physical forms, including glass tube fuses (common in older models), blade-style automotive fuses, or sometimes as surface-mount fuses directly on the printed circuit board.

- Short Circuit: A direct path for current to flow, bypassing the normal resistance, causing a sudden and large surge.

- Overload: The gate motor or another component drawing more current than it's designed for, perhaps due to mechanical obstruction, a faulty motor, or issues with the gate's movement (e.g., binding hinges, gate dragging on the ground).

- Component Failure: A faulty component on the control board or within the gate operator system itself can cause an abnormal current draw, leading the fuse to blow.

- Power Surges: External power surges from the main electrical supply or lightning strikes can also cause fuses to blow.

- Disconnect Power: Always disconnect all power to the gate operator before attempting any inspection or repair. This includes both AC power and any battery backup systems.

- Locate the Fuse: The fuse is typically located directly on the main control board, often in a small holder or a clear cover. Refer to your gate operator's manual for its exact location.

- Inspect the Fuse:

- For glass tube fuses, you can often visually inspect the wire inside; if it's broken or discolored, the fuse is blown.

- For blade-style fuses, there might be a visible break in the metal strip, or you can use a multimeter set to continuity mode. A blown fuse will show no continuity.

- Replace the Fuse: If the fuse is blown, replace it with a new fuse of the exact same amperage (ampere) and voltage rating. Using a fuse with a higher rating can lead to damage to the control board or other components, as it won't blow when it should. Using a lower rating may cause the fuse to blow unnecessarily.

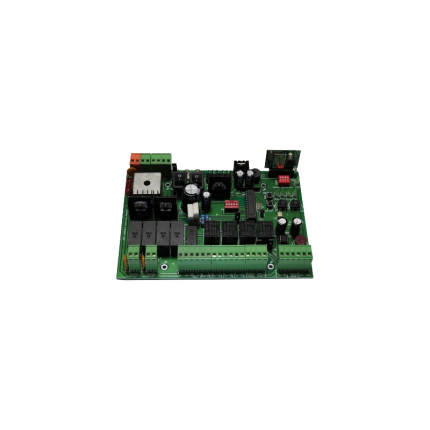

Gate operator main control board – Key Automation

Ship or pick up from our office.

Gate operator main control board – Key Automation

A swing gate operator's main control board is the "brain" of the system, responsible for managing all the functions of the gate opener.

It receives signals from various input devices like remote controls, keypads, and safety sensors, and then directs the gate motor to open or close the gate accordingly. The control board also manages other aspects of the gate operation, such as adjusting speed, setting timers, and implementing safety features.

Here's a more detailed breakdown:

-

Central Control:The control board acts as the central hub for all gate operations.

-

Signal Processing:It receives signals from different devices (remote, keypad, safety sensors).

-

Motor Activation:Based on the received signal, the control board sends instructions to the motor to open or close the gate.

-

Adjustable Settings:Many control boards allow for adjustments to gate speed, opening/closing times, and safety settings.

-

Safety Features:Some control boards manage security features like locking mechanisms and safety protocols.

-

Power Supply:The control board is usually powered by a specific voltage (e.g., 120 volts) and may have an output voltage for powering other accessories.

-

Internal Receiver:Some control boards have built-in radio receivers for remote control operation.

Metal Case Diode Bridge KBPC5010

Ship or pick up from our office.

Metal Case Diode Bridge KBPC5010

The Metal Case Diode Bridge KBPC5010 is a specific type of bridge rectifier, a crucial electronic component used to convert alternating current (AC) into direct current (DC). It is widely employed in various power supply applications. Here's a breakdown of its key features and what each part of its name signifies: What is a Bridge Rectifier? A bridge rectifier is a circuit of four (or more) diodes in a specific configuration that allows for full-wave rectification. This means it efficiently converts both the positive and negative half-cycles of an AC input into a pulsating DC output. Compared to simpler half-wave rectifiers, bridge rectifiers are more efficient and provide a smoother DC output. KBPC5010 Explained- KBPC: This is typically a series designation for a family of single-phase bridge rectifiers with specific package styles.

- 50: This number indicates the maximum average forward rectified current (Io) the device can handle, which in this case is 50 Amperes (A). This high current rating makes it suitable for demanding applications.

- 10: This number typically refers to the voltage class, often indicating a maximum repetitive peak reverse voltage (VRRM) of 1000 Volts (V) (where '10' often means 10 x 100V). This high voltage rating allows it to handle substantial AC input voltages.

- Conversion: Converts single-phase AC to pulsating DC.

- Current Rating: Up to 50 Amperes (A) average forward current.

- Voltage Rating: Up to 1000 Volts (V) repetitive peak reverse voltage.

- Surge Current Capability: Often capable of handling high non-repetitive surge currents (e.g., 400A or 450A for a short duration), which is crucial for handling initial power-on transients.

- Low Forward Voltage Drop: Minimizes power loss and improves efficiency.

- High Reliability: Designed for robust performance in various environments.

- Mounting: Typically features through-hole mounting with a screw hole for chassis or heatsink mounting.

- Terminals: Often uses 0.25" (6.35 mm) Faston terminals for easy connection. Some variants (like KBPC5010W) might have wire leads.

- Operating Temperature: Wide operating junction temperature range, often from -40°C to +150°C.

- Power supplies: As a core component to rectify AC mains voltage into DC for electronic devices.

- Battery chargers: Converting AC power to DC for charging batteries.

- Motor control circuits: Providing DC power for electric motors.

- Industrial control systems: Used in various industrial applications requiring AC-to-DC conversion.

- Input rectifiers for variable frequency drives (VFDs).

Programmer module -Key Automation KUBEPRO

Ship or pick up from our office.

PRODUCT SHEET PDFProgrammer module -Key Automation KUBEPRO

*KUBEPRO - Installer Version *Smartphone programming for 14A and HALO control boardsThe Key Automation KUBEPRO is a programmer module that allows professional installers to configure and manage Key Automation gate and door operators using a smartphone.

It connects via Bluetooth to the installer's smartphone and allows them to adjust parameters, set up the gate opener, and manage other aspects of the automation system.

The KUBE PRO also includes the KEY CLOUD service for data viewing, backup, team management, and maintenance scheduling.

Here's a more detailed breakdown:

-

Purpose:The KUBEPRO is designed for professional installers to configure and manage Key Automation gate and door operators.

-

Functionality:It allows installers to adjust various parameters, set up the gate opener, and manage other settings directly from their smartphone.

-

Connectivity:It connects to the gate operator's control board and uses Bluetooth to communicate with the installer's smartphone.

-

Smartphone App:An app, specifically designed for professional installers, is used to interact with the KUBEPRO module.

-

KEY CLOUD:The KUBE PRO module includes KEY CLOUD, a cloud-based service for storing data, managing teams, and scheduling maintenance.

-

Accessibility:The KUBE PRO module is restricted to users with a Key Automation account, ensuring proper authorization and usage.

Radio receiver RG433-12V1C

Ship or pick up from our office.

Radio receiver RG433-12V1C

* DC 12 V * 1 Channel * 433 MHz The RG433-12V1C is a single-channel radio receiver operating at 433 MHz, specifically designed for remote control of automatic gates. It acts as a crucial component in automated gate systems, allowing users to open and close gates wirelessly using a remote control. This receiver is compact and lightweight, making it easy to install. It functions by receiving radio signals from a remote, decoding the commands, and then controlling the gate opener mechanism. Key Features- Frequency: Operates at 433 MHz, a common frequency for remote control devices.

- Channels: It's a 1-channel receiver, meaning it can control one specific function or device (in this case, typically opening/closing a single gate).

- Voltage: Designed to operate with a 12V DC power supply.

- Application: Primarily used in automated gate systems for remote access control.

- Dimensions: Approximately 8 × 6 × 3 cm.

- Weight: Around 0.08 kg.

- Compatibility: Compatible with various types of gate openers, including single swing, double swing, and sliding gates.

Sliding gate operator control board SLRG110

Ship or pick up from our office.

Sliding gate operator control board SLRG110

The SLRG110 is a universal main control board for sliding gate operators that runs on 110-volt AC power.

It acts as the "brain" of a sliding gate system, managing its core functions.

Here's a breakdown of what the SLRG110 offers:

Core Functionality

- Motor Control: It receives signals from various access devices (like remote controls or keypads) and translates them into commands to control the gate's motor, initiating opening, closing, and stopping movements.

- Power Management: It receives power from a 110V AC source and directs it to the gate motor and other connected accessories.

- Adjustable Settings: The board typically allows for customization of gate operation, including:

- Adjustable speed settings for both opening and closing.

- Adjustable auto-close timer (e.g., 0, 30, 60, 90 seconds).

- Adjustable torque and closing force to suit different gate weights and preferences.

- Ability to add and delete remote controls easily.

- Option to set auto-close when power is restored after an outage.

Key Features & Safety

- Obstruction Detection: A crucial safety feature, the SLRG110 can detect obstructions in the gate's path during movement and automatically stop or reverse the gate to prevent damage or injury.

- This often utilizes infrared detection connectors for photocells.

- Remote Control Capability: It's designed to work seamlessly with remote controls for convenient operation.

- Emergency Release: The system usually includes an emergency release key for manual operation in case of power failure.

- Limit Switches: It connects to limit switches (often magnetic) that define the gate's fully open and closed positions, preventing overtravel.

- Accessory Inputs: The board has various input terminals for connecting additional accessories like:

- Photocells (safety beams)

- Manual push buttons

- Wired keypads

- GSM inputs (for remote access via mobile networks)

- Vehicle sensor exit wands

Universal Compatibility

The SLRG110 is considered a universal control board, meaning it's designed to be compatible with a wide range of sliding gate opener models.

This makes it a versatile replacement option for existing systems. It can operate gates weighing up to approximately 1750-1760 lbs.

Sliding gate operator main control board – Difermatic

Ship or pick up from our office.

Sliding gate operator main control board – Difermatic

The main control board for a Difermatic sliding gate operator, such as the DSL600, acts as the "brain" of the system, managing all the gate's functions.

It receives commands from remote controls or other inputs, and then controls the motor to open and close the gate. It also manages safety features like obstacle detection and may allow for adjustments to speed, force, and other parameters.

Key Functions:

- Receives and Processes Commands: The control board receives signals from remote controls, keypads, or safety sensors.

- Controls the Motor: It sends instructions to the gate's motor to open or close the gate based on the received commands.

- Manages Safety Features: Many control boards include safety features like obstacle detection (which can reverse the gate's direction if it encounters an obstruction) and slow-down functions.

- Adjustable Settings: Some models allow for adjustment of speed, force, and other parameters.

- Power Supply: The control board typically operates on a 24V power supply.

Specific to Difermatic:

- The Difermatic DSL600 is a 600kg sliding gate opener, indicating the weight capacity of the gate it's designed to handle.

- Difermatic products are known for their Italian design and quality.

- The control board likely has features like remote control operation, safety mechanisms, and adjustable speed and force settings.

Additional Notes:

- Many sliding gate control boards, including those from Difermatic, are designed for easy installation and user-friendly operation.

- They often include a built-in receiver for remote controls and may be compatible with other accessories like photocells and alarm lamps.

- Some control boards also feature automatic closing functions and can be programmed for various delay times.

Sliding gate operator main control board – Key Automation

Ship or pick up from our office.

Sliding gate operator main control board – Key Automation

The main control board for a Key Automation sliding gate operator, like the SUN7224 or SUN11024, is the central processing unit that manages the gate's movement, safety features, and other functionalities.

It receives signals from remote controls, keypads, or sensors, and then directs the motor to open or close the gate accordingly.

Here's a more detailed explanation:

-

Core Function:The control board acts as the "brain" of the gate system, interpreting signals and controlling the motor.

-

Input:It receives signals from various input devices, such as remote controls, keypads, or safety sensors.

-

Output:It sends commands to the motor to start, stop, reverse, or adjust its speed based on the input received.

-

Safety Features:Many control boards include safety features like obstacle detection, which can automatically stop or reverse the gate if it encounters an obstruction.

-

Programming and Diagnostics:Some control boards offer programming capabilities and diagnostic displays to simplify setup and troubleshooting.

-

D-Track Technology:Some Key Automation models, like the Deimos, utilize D-Track technology for precise torque management and impact detection.

-

Power Supply:Control boards typically operate on a specific voltage (e.g., 24V DC or 110V AC).

Sliding gate operator main control board – VDS

Ship or pick up from our office.

Sliding gate operator main control board – VDS

The VDS SIMPLY sliding gate operator's main control board is the central unit that controls the operation of a sliding gate, typically one that weighs up to 600kg.

It's made by VDS Automation, an Italian company known for its gate automation products.

This control board manages functions like opening and closing the gate, potentially adjusting speed and force, and integrating with accessories such as keypads and safety sensors.

-

Central Control:The control board acts as the brain of the gate, receiving signals from remote controls or other input devices and translating them into actions for the gate's motor and other components.

-

Remote Control Integration:It typically includes a built-in radio receiver that can be programmed to work with VDS remote controls.

-

Safety Features:The control board can manage safety mechanisms like anti-squashing systems and potentially adjustable speed and force settings.

-

Easy Installation and Programming:The VDS SIMPLY control board is designed for easy installation, often featuring pre-wired components and straightforward programming.

-

Optional Accessories:It can be integrated with optional accessories like keypads, safety sensors, and other components to enhance functionality.

-

Durability:The control unit is often housed in a box with an air-stop seal to protect it from moisture and insects, and the mechanical parts may be lubricated with lithium grease for longevity.

-

Italian Manufacturing:VDS (Simply SL110) is specifically mentioned as an Italian-made control board, emphasizing quality and reliability.

Sliding gate operator main control board – Zero

Ship or pick up from our office.

Sliding gate operator main control board – Zero

The sliding gate operator main control board (also referred to as a PCB or circuit board) is the central component that manages all the functions of an automatic sliding gate system.

It acts as the "brain" of the gate, receiving signals from various input devices (like remote controls, keypads, or safety sensors) and translating them into actions for the gate's motor and other components.

Here's a more detailed breakdown:

1. Central Control: The control board is the central hub for all gate operations. It receives signals from different sources, such as:

- Remote controls: For opening and closing the gate.

- Keypads: For authorized access.

- Safety sensors: To detect obstructions and prevent accidents.

- Other accessories: Such as loop detectors, intercom systems, etc.

2. Signal Processing: The control board interprets the signals it receives and determines the appropriate action for the gate.

3. Motor Activation: Based on the processed signal, the control board sends instructions to the gate's motor to either open or close the gate.

4. Adjustable Settings: The control board often allows for adjustments to various parameters, including:

- Gate speed: The speed at which the gate opens and closes.

- Opening and closing timers: To control the duration of the gate's movement.

- Safety features: Including force adjustments, obstacle detection sensitivity, and slow-down settings.

Swing gate operator control board SWRG110

Ship or pick up from our office.

Swing gate operator control board SWRG110

The SWRG110 is a universal swing gate operator control board designed to manage the operation of AC (Alternating Current) powered swing gate motors. It's essentially the "brain" of a swing gate automation system, responsible for controlling the gate's movement, safety features, and integration with various accessories. It's often marketed as a replacement or upgrade board due to its broad compatibility with different AC swing gate openers, particularly those operating at 110V or 220V. Key Features and Functionality The SWRG110, as a universal control board, typically offers a range of features for efficient and safe gate operation:- Motor Control: It manages the power supply and direction of one or two AC gate motors, allowing for opening and closing cycles. It can be used for both single and double swing gates.

- Soft Start/Stop: This feature ensures a smooth and gradual acceleration and deceleration of the gate, reducing wear and tear on the motor and mechanical components, and providing quieter operation.

- Obstacle Detection: A crucial safety feature, obstacle detection allows the gate to stop or reverse if it encounters an obstruction during its movement, preventing damage to the gate, vehicle, or injury to people or pets. This is often achieved through current sensing or external safety sensors like photocells.

- Automatic Close: This function allows the gate to automatically close after a set period of time, enhancing security and convenience.

- Limit Switches: The board interfaces with limit switches (often magnetic or mechanical) to define the full open and full closed positions of the gate, ensuring precise stopping.

- Remote Control Learning: It typically has a learning function to pair with wireless remote controls, allowing users to open and close the gate from a distance.

- Accessory Interfaces: The SWRG110 provides terminals for connecting various gate accessories, such as:

- Photocells/Infrared Sensors: For enhanced safety and obstacle detection.

- Warning Lights: To signal gate movement.

- Keypads/Intercoms: For controlled access.

- GSM Modules/Phone APP integration: Some versions may offer connectivity for remote control via smartphone.

- Wall Buttons: For manual operation from inside the property.

- Exit Wands/Vehicle Sensors: To automatically open the gate for exiting vehicles.

- Adjustable Settings: Many control boards like the SWRG110 offer adjustable parameters, such as:

- Motor power/force (especially for obstacle detection sensitivity).

- Slowdown speed.

- Automatic close timer.

- Working time for each motor.

- Diagnostic Display: Some models include an LED or LCD display for easier setup, programming, and troubleshooting of errors.

- AC Powered Motors: Specifically, 110V or 220V AC swing gate motors. It's not compatible with DC (12V or 24V) motors.

- Various Gate Opener Models: It can replace control boards in numerous existing swing gate openers, such as some ALEKO and Lockmaster models.

- Power Disconnection: Safely disconnecting power to the gate opener.

- Wiring: Connecting the motor, power supply, and accessories to the appropriate terminals on the SWRG110 board. Understanding terminal functions is crucial for correct wiring.

- Programming: Learning remote controls and adjusting settings (e.g., limit switch calibration, auto-close time) according to the specific gate and desired operation.