Shop

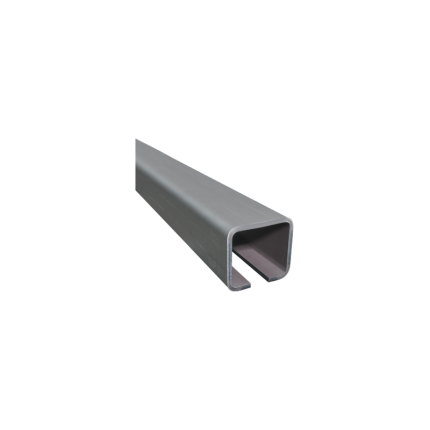

Cantilever sliding gate track

Ship or pick up from our office.

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

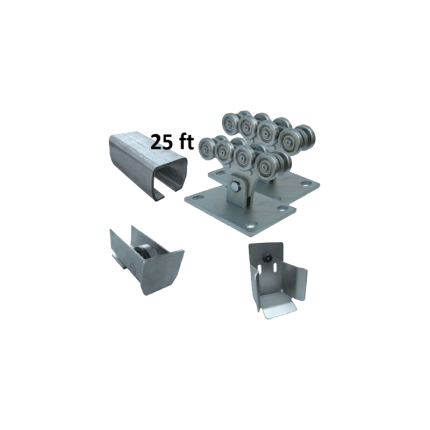

Cantilever Sliding Gate Hardware

Ship or pick up from our office.

Cantilever Sliding Gate Hardware

Cantilever sliding gate hardware refers to the specialized components that allow a gate to slide open and close without needing a track on the ground. Instead, the gate is supported and guided from above and to the side by a system of rollers and channels. Here's a breakdown of the essential components that make up cantilever sliding gate hardware:- Cantilever Track (or Rail):

- This is the most distinctive part. It's a heavy-duty, usually C-shaped (or sometimes a more complex extruded profile) channel that's securely attached to the bottom (or sometimes top) of the gate frame itself.

- The track is extended beyond the main gate opening to form the "tail" or counterbalance section, which supports the gate when it's fully open.

- Materials: Commonly made from galvanized steel for strength and corrosion resistance, or aluminum for lighter weight and superior corrosion resistance (as discussed previously).

- Cantilever Carriages (or Trolleys/Rollers):

- These are the critical load-bearing components. They consist of a sturdy base plate with multiple wheels (often 5, 8, or more) arranged in a specific configuration.

- The wheels are made from durable materials like steel (often machined or cast) or high-impact nylon, and typically feature sealed bearings for smooth, maintenance-free operation.

- The cantilever track fits over these carriages, with the wheels rolling inside the track's channel.

- Two (or more for very long/heavy gates) carriages are typically mounted on strong concrete foundation posts, positioned outside the gate opening. These posts support the entire weight of the gate.

- Guide Rollers/Plates (Upper Guides):

- These are smaller rollers or plates mounted on a separate guide post (or posts) on the same side as the cantilever carriages.

- Their purpose is to keep the gate upright and prevent it from tipping over as it moves. They typically engage with the top rail of the gate.

- Made from nylon, steel, or a combination, often with adjustable brackets.

- End Cups / Receiver Posts / Gate Catches:

- End Cup (or End Stop): A cup or bracket mounted on the support posts at the fully closed position. The end of the gate's tail section (specifically the track) "rests" in this cup when the gate is fully closed, providing additional stability and support.

- Receiver Post / Gate Catch: A post or latching mechanism at the opposite end of the gate opening. When the gate is fully closed, it engages with this post to secure the gate in the closed position. This is often where a lock or the gate operator's arm connects.

- Support Wheels / Final Wheels: Sometimes, a small support wheel is mounted on the ground or a low post at the far end of the gate opening to provide extra support to the gate's leading edge when it's fully closed, especially for very long or heavy gates.

- Anchoring and Installation Accessories:

- Foundation Plates/Anchor Bolts: Heavy-duty plates and bolts used to securely anchor the cantilever carriages to concrete foundations. The stability of the entire system relies on robust anchoring.

- Tension Bars (less common in modern designs): Historically used for minor adjustments to gate alignment or sag, though modern systems are often designed to minimize this need.

- No Ground Track: This is the primary advantage. Eliminates the need for a track embedded in the driveway, which means:

- No debris accumulation (leaves, dirt, snow, ice) obstructing movement.

- Smoother operation on uneven driveways.

- Less maintenance in terms of track cleaning.

- No tripping hazard or wear on vehicles crossing a ground track.

- Durability and Low Maintenance: Because the main rolling components (carriages) are elevated and enclosed within the track, they are less exposed to dirt and weather, leading to longer life and less frequent maintenance.

- High Security: Cantilever gates are inherently very secure as they are difficult to lift or derail.

- Aesthetics: The absence of a ground track can contribute to a cleaner, more streamlined look for the driveway entrance.

- Suitable for High-Traffic Areas: Their robust design makes them ideal for commercial, industrial, or busy residential applications.

- Gate Automation and Supply Companies: Businesses specializing in automatic gates will carry a full range of cantilever hardware. Examples include Royal Gates (Royal Electronic Technology Center Co.), presence in the Metro Vancouver area, including Surrey.

- Fencing and Gate Fabricators: Many companies that custom-fabricate gates will also supply or install the necessary hardware.

- Industrial Hardware Suppliers: Larger industrial suppliers may stock components, though specialized gate companies will offer more comprehensive systems.

- Online Retailers: Many online suppliers ship to Canada, offering a wide variety of components from different manufacturers.

Sliding gate V-Groove wheels -SLGWS800

Ship or pick up from our office.

Sliding gate V-Groove wheels -SLGWS800

Sliding gate V-Groove wheels are a fundamental component in a common type of sliding gate system. Unlike cantilever gates that hang above the ground, these gates roll directly on a track installed on the ground. Here's a detailed explanation: What they are: A V-Groove wheel is a type of wheel specifically designed with a V-shaped groove machined into its circumference. This groove perfectly mates with a corresponding V-shaped track, which is usually made of angle iron or a similar steel profile. How they work:- Track Installation: A V-shaped steel track is securely laid and typically anchored into the driveway or ground along the entire length of the gate's travel path. This track acts as the "railroad track" for the gate.

- Wheel Attachment: The V-Groove wheels are attached to the bottom frame of the sliding gate. Depending on the gate's length and weight, multiple wheels will be strategically placed along its underside.

- Guidance and Support: As the gate opens or closes (either manually or with a gate opener), the V-shaped groove of the wheels sits snugly onto the V-shaped track. This tight fit ensures:

- Smooth and Stable Movement: The gate rolls smoothly and without wobbling or derailing.

- Guidance: The wheels effectively guide the gate in a straight line, preventing it from veering off course.

- Load Distribution: The wheels bear the weight of the gate, distributing it evenly along the track.

- Materials: V-Groove wheels are typically made from durable materials to withstand heavy loads and wear:

- Steel (most common): Offers high strength, load capacity, and durability. Often zinc-plated or galvanized for corrosion resistance.

- Cast Iron: More economical but can be more prone to breakage than steel, and may require more frequent lubrication.

- Nylon or High-Impact Polymer: Quieter in operation and excellent for corrosion resistance, but generally have lower load capacities than steel and may not last as long under heavy use.

- Bearings: High-quality V-Groove wheels incorporate sealed bearings (like precision ball bearings). These reduce friction, ensure smooth rolling, and often require no lubrication, making them "maintenance-free."

- Sizes: Available in various diameters (e.g., 3", 4", 6") and load capacities (ranging from hundreds to thousands of pounds per wheel) to suit different gate sizes and weights.

- With or Without Brackets: Some wheels come with integrated mounting brackets for easier installation, while others are just the wheel itself, requiring a custom bracket or housing.

- Stability and Alignment: The V-groove design provides excellent stability, keeping the gate perfectly aligned with the track and preventing it from tilting or derailing.

- High Load Capacity: Especially steel V-Groove wheels, they are designed to handle very heavy gates, making them suitable for large residential, commercial, and industrial applications.

- Durability and Longevity: Made from robust materials, they offer a long service life, particularly with sealed bearings.

- Relatively Simple System: The concept is straightforward, and the components are widely available.

- Ground Track Maintenance: The main drawback compared to cantilever gates is that the ground track can accumulate debris (leaves, dirt, snow, ice). This debris must be regularly cleaned to ensure smooth operation and prevent damage to the wheels or opener. In Surrey, BC's climate, this is an important consideration due to rain and potential for snow.

- Driveway Disruption: Installing a ground track requires cutting into or modifying the driveway surface.

- Noise: While smoother than some other wheel types, they can still produce some noise, particularly if the track is not perfectly clean or if the wheels are worn.

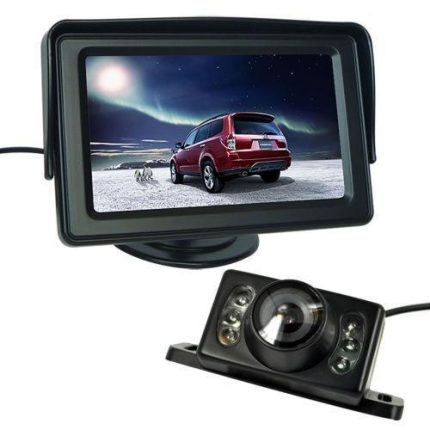

Car back-up camera

Ship or pick up from our office.

Car back-up camera

A car back-up camera, also widely known as a rearview camera or reversing camera, is a specialized video camera mounted on the rear of a vehicle. Its primary function is to provide the driver with a visual feed of the area directly behind the car when the vehicle is in reverse. This significantly enhances safety and convenience, especially when parking or maneuvering in tight spaces. How it Works:- Camera Placement: The camera is typically small and discreetly mounted on the rear of the vehicle. Common locations include near the license plate, integrated into the trunk handle, or within the rear bumper.

- Activation: When the driver shifts the vehicle into REVERSE gear, the back-up camera automatically activates.

- Video Feed: The camera captures a wide-angle video image of the area behind the car.

- Display: This live video feed is then displayed on a screen inside the vehicle. This screen can be:

- An integrated display in the dashboard (common in newer vehicles).

- A dedicated monitor that mounts on the dashboard.

- A replacement rearview mirror with an integrated screen.

- An aftermarket car stereo head unit with a video input.

- Deactivation: When the driver shifts out of reverse, the camera typically turns off.

- Enhanced Safety: This is the most crucial benefit. Back-up cameras dramatically reduce blind spots behind the vehicle, helping drivers avoid collisions with:

- Pedestrians: Especially children and pets who may not be visible in rearview mirrors.

- Obstacles: Such as bollards, low walls, fire hydrants, or other vehicles.

- Improved Parking: Makes parallel parking and backing into parking spots much easier and more precise.

- Parking Guidelines: Many systems overlay dynamic (move with steering wheel input) or static lines on the screen to help the driver estimate distance and trajectory.

- Night Vision/Low-Light Capability: Many cameras are equipped with enhanced low-light sensors or infrared (IR) LEDs to provide a clear image even in dark conditions.

- Wide Viewing Angle: Essential for comprehensive coverage, typically offering 120 to 170 degrees of view to minimize blind spots.

- Weather Resistance: Since they are mounted externally, backup cameras are designed to be waterproof and dustproof (often with an IP67 rating or higher).

- Integration with Other Systems: Some advanced systems integrate with parking sensors (audible warnings) and Rear Cross-Traffic Alert (warns of approaching vehicles from the sides when backing out of a spot).

- Wired vs. Wireless:

- Wired cameras: Offer a more reliable connection and typically higher video quality, but require running cables through the vehicle.

- Wireless cameras: Easier to install as they transmit the video feed wirelessly, but can sometimes be susceptible to interference or have lower resolution.

Car parking sensor kit

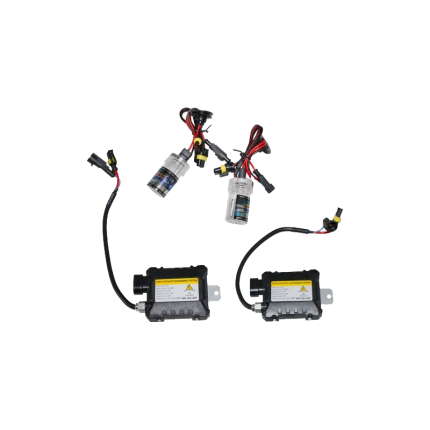

Vehicle HID light kit

Ship or pick up from our office.

Vehicle HID light kit

A vehicle HID (High-Intensity Discharge) light kit is an aftermarket product designed to convert a vehicle's standard halogen headlights to HID lighting. HID lights, also known as Xenon lights, produce light by igniting noble gases (like xenon) within a sealed bulb using an electric arc, rather than by heating a filament like traditional halogen bulbs. Components of a Typical HID Light Kit: A complete HID light kit generally consists of the following key components for each headlight:- HID Bulbs: These are the actual light sources. Unlike halogen bulbs, they don't have a filament. Instead, they contain xenon gas and metal salts. They come in various bulb sizes (e.g., H1, H7, 9006, D2S) to match the original halogen bulb fitment of a vehicle's headlight housing. They also come in different "color temperatures" measured in Kelvin (K), ranging from yellow-white (around 3000K-4300K) to pure white (5000K-6000K) and blue-white (8000K+).

- Ballasts (Igniters/Power Converters): This is the most crucial part of an HID kit. Halogen bulbs operate on 12V DC, but HID bulbs require a very high voltage (tens of thousands of volts) to ignite the gas and then a stable, lower voltage (around 85V AC) to keep the arc sustained. The ballast performs this function:

- Ignition: It provides the initial high-voltage pulse to ignite the xenon gas.

- Regulation: Once ignited, it regulates the current and voltage to the bulb to maintain a stable arc and optimal light output.

- Canbus Ballasts: Many modern vehicles use a "CAN bus" (Controller Area Network) system that monitors electrical circuits. If the vehicle detects a lower power draw from HID bulbs compared to original halogens, it might throw a "bulb out" error or cause flickering. "Canbus ballasts" are designed to mimic the electrical load of halogen bulbs to prevent these errors.

- Wiring Harness (Optional but Recommended): In some cases, particularly for vehicles with sensitive electrical systems or DRLs (Daytime Running Lights) that operate at reduced voltage, a relay wiring harness is used. This harness draws direct power from the battery, ensuring the ballasts receive consistent 12-14V, with the original headlight wiring acting only as a trigger.

- Capacitors/Resistors (Optional): These may be included or sold separately to address specific vehicle electrical issues like flickering (capacitors) or "bulb out" warnings (resistors), especially in vehicles with pulse width modulation (PWM) in their headlight circuits.

- Brightness (Lumen Output): HID lights are significantly brighter than standard halogen bulbs, offering more light output on the road.

- Color Temperature: Many users prefer the whiter or bluer light of HIDs, which often looks more modern and can improve visibility of road signs.

- Energy Efficiency: While brighter, HIDs can sometimes be more energy-efficient than halogens for the amount of light they produce.

- Lifespan: HID bulbs generally have a longer lifespan than halogen bulbs, though ballasts can fail.

- Glare and Light Distribution: Halogen headlight housings (reflectors or projectors) are precisely engineered to work with the light-emitting point and light distribution pattern of a halogen filament. When an HID bulb (which has a different light source and emits light differently) is placed in a housing designed for halogen, it creates an uncontrolled and often excessive amount of glare. This can blind oncoming drivers, creating a significant safety hazard.

- BC Motor Vehicle Act Regulations (Section 4.02 & 4.04): These regulations generally state that vehicle lamps must comply with original manufacturer specifications and approved standards (like SAE) and must not cause undue glare or dazzle oncoming traffic. Specifically, if a headlight housing is marked for a Halogen (HR) bulb, it is unlawful to put an HID (HG) light source in it.

- DOT/SAE Compliance: Aftermarket HID conversion kits typically do not meet DOT (Department of Transportation) or SAE (Society of Automotive Engineers) standards for the entire headlight assembly when installed in a halogen housing. Only complete headlight assemblies that are factory-designed for HIDs and meet these standards are truly legal.

- Enforcement in BC/Canada: While enforcement can vary, police in BC and across Canada can issue tickets (e.g., a $110 fine under the Highway Traffic Act) and potentially even order vehicles off the road for non-compliant lighting that causes excessive glare. They often look for vehicles with "uncontrolled" light output, especially if it's causing complaints.

- Best Practice: Projector Retrofits: To legally and safely upgrade to HID lighting, the proper method is a "retrofit." This involves replacing the entire headlight housing (or at least the internal projector lens assembly) with one specifically designed for HID bulbs. This ensures the light is properly focused and distributed, preventing glare. However, this is a more complex and expensive process than simply installing a "kit."

Car alarm shock sensor

Ship or pick up from our office.

Car alarm shock sensor

A car alarm shock sensor is a critical component of a vehicle's security system designed to detect physical impacts or vibrations to the car. Its primary purpose is to trigger the alarm if someone attempts to break into the vehicle, tamper with it, or even tow it away. How it Works: The core principle behind a shock sensor is that it measures the intensity of vibrations or impacts. Most modern shock sensors are piezoelectric or electromagnetic, and they typically work in a dual-stage manner to reduce false alarms:- Detection of Vibration/Impact:

- When the car experiences a physical disturbance (e.g., a window being hit, someone trying to pry open a door, a car next to it bumping it, or even a strong bass from a passing vehicle), the shock sensor registers this as a vibration or impact.

- Internally, the sensor often contains a small weight or a piezoelectric crystal that moves or generates a voltage when subjected to mechanical stress. This movement or voltage change is converted into an electrical signal.

- Sensitivity Adjustment and Dual-Stage Triggers:

- Modern shock sensors are usually adjustable in terms of sensitivity. This is crucial to prevent false alarms from minor disturbances (like a loud truck passing by or someone lightly tapping the car).

- Many high-quality sensors are dual-stage or multi-stage:

- Light Impact (Pre-warning/First Stage): If a minor impact or vibration is detected (e.g., someone bumps the car, or a strong wind rattles it), the sensor sends a "pre-warning" signal to the alarm control unit. This typically results in a short series of chirps from the alarm or a warning flash of the lights. This is designed to deter a potential intruder without fully setting off the alarm.

- Heavy Impact (Full Alarm/Second Stage): If a more significant impact or sustained vibration is detected (e.g., a window being smashed, a door being forced open, or the vehicle being jacked up for wheel theft), the sensor sends a "full alarm" signal. This triggers the main alarm, sounding the siren, flashing the lights, and potentially sending an alert to the owner's remote or smartphone.

- Single-Stage: Triggers the full alarm for any detected shock above a certain threshold. (Less common in modern systems due to false alarm potential).

- Dual-Stage (or Dual-Zone): As described above, offers a warning chirp for light impacts and a full alarm for heavy impacts. This is the most common and effective type.

- Digital Shock Sensors: These are more advanced, using microprocessors to analyze the vibration patterns. They can often differentiate between different types of impacts (e.g., a window break vs. a passing truck) and are less prone to false alarms.

- Integrated with Other Sensors: Some advanced alarm modules now combine shock sensing with other functions like tilt sensing (to detect towing) or even glass-break detection (listening for the specific sound of breaking glass) into a single unit (e.g., Compustar's FT-DAS-II sensor).

- Early Detection: Can detect an attempted break-in before a door or hood is even opened.

- Comprehensive Protection: Provides protection for the entire vehicle body, including windows, wheels, and the undercarriage (against jacking).

- Deterrent: The warning chirps often scare off potential thieves.

- Sensitivity Adjustment is Key: Proper installation and calibration of the shock sensor are crucial. If it's too sensitive, it will cause false alarms due to loud vehicles, thunder, or even heavy rain. If it's not sensitive enough, it might not detect a genuine threat. Professional installation is highly recommended to ensure optimal performance.

- Environmental Factors: Vibrations from heavy trucks, construction, or even strong winds can sometimes trigger poorly adjusted sensors.

- Not a Standalone Solution: While important, a shock sensor is usually part of a comprehensive alarm system that also includes door/hood/trunk sensors, and sometimes ultrasonic or tilt sensors for maximum protection.

Vehicle alarm ultrasonic sensor

Ship or pick up from our office.

Vehicle alarm ultrasonic sensor

A vehicle alarm ultrasonic sensor is a type of motion sensor used in car alarm systems to detect movement within the interior of a vehicle when the alarm is armed. It's designed to provide an extra layer of security by catching intruders who might try to gain access by breaking a window or otherwise entering the cabin without opening a door. Here's how it generally works:- Emission of Ultrasonic Waves: When the car alarm system is armed, the ultrasonic sensor (or typically a pair of sensors, one on each side of the front of the vehicle, often mounted on the A-pillars) emits high-frequency sound waves. These sound waves are beyond the range of human hearing, hence "ultrasonic." These waves fill the interior space of the vehicle.

- Monitoring for Echoes: The sensor continuously monitors the echoes of these sound waves as they bounce off the surfaces within the car's cabin (seats, dashboard, windows, roof, etc.). This creates a consistent pattern of reflected waves.

- Detection of Disturbance: If an intruder enters the vehicle, or if there's any significant movement within the cabin (e.g., someone reaches in through a broken window, or a pet is left inside and moves around), this movement disrupts the established pattern of the ultrasonic waves. The sound waves bounce back differently, indicating a change in the air pressure or the environment within the car.

- Alarm Trigger: When the sensor detects this disturbance or change in the reflected wave pattern, it signals the car's alarm system. The alarm then triggers, typically sounding the horn, flashing the lights, and in some cases, activating a dedicated siren.

- Interior Protection: Its primary purpose is to detect intrusion into the passenger compartment, complementing other sensors like door, hood, and trunk sensors.

- Invisible Barrier: It creates an "invisible" protective barrier within the vehicle's cabin.

- Sensitivity: Ultrasonic sensors are quite sensitive and can detect even minor movements, which makes them effective against various forms of unauthorized entry.

- False Alarm Reduction: Quality ultrasonic sensors are designed to minimize false alarms. However, factors like leaving windows open, a sunroof ajar, or having pets or large insects inside the car can sometimes trigger them.

- Compatibility: They are often integrated into factory-installed alarm systems in newer vehicles, but can also be added as aftermarket components to enhance existing security systems.

- Adjustable Sensitivity: Many systems allow for adjustment of the sensor's sensitivity to tailor its performance to different environments or situations.

- Not for Convertibles: Due to their reliance on enclosed air space and reflected sound waves, ultrasonic sensors are generally not suitable for convertibles or vehicles with soft tops, as the open or flexible roof would not properly reflect the sound waves, leading to false alarms or ineffective monitoring.

Glass Break Sensor

Vehicle central door lock actuator

Ship or pick up from our office.

Vehicle central door lock actuator

A vehicle central door lock actuator is the electromechanical component responsible for physically locking and unlocking your car's doors when you press a button on your key fob, the interior door switch, or when the central locking system otherwise activates (e.g., speed-sensitive locking). Think of it as the "muscle" of your car's power door locks. Here's a more detailed breakdown: How it Works:- Signal Transmission: When you press the lock or unlock button on your key fob (remote control) or the switch inside the car, a radio frequency signal or an electrical signal is sent to the vehicle's Electronic Control Unit (ECU), often referred to as the Body Control Module (BCM).

- Processing by ECU: The ECU decodes this signal and determines whether the command is to lock or unlock the doors.

- Actuator Activation: The ECU then sends an electrical current to the door lock actuator located inside each door.

- Mechanical Movement: The actuator contains a small electric motor, a set of gears, and linkages (or sometimes a cable).

- When the motor receives the electrical current, it rotates in one direction to engage the locking mechanism (locking the door) or in the opposite direction to disengage it (unlocking the door).

- The gears amplify the motor's force, and the linkages convert the rotational motion of the motor into the linear or pivotal motion needed to move the door latch and lock/unlock the door.

- Feedback (Optional): Some systems provide feedback, such as a light flash or a horn chirp, to confirm that the doors have been locked or unlocked.

- Electric Motor: A small, reversible DC motor that provides the power.

- Gear Train: A series of gears that transmit and multiply the motor's torque to move the locking mechanism.

- Linkages/Cable: Connect the internal mechanism of the actuator to the door's actual latching mechanism.

- Electrical Contacts/Switches: These are inside the actuator and tell the ECU the current state of the lock (locked or unlocked).

- Housing: Encapsulates and protects all the internal components.

- Motor-driven Actuators (Most Common in Modern Cars): As described above, these use a small electric motor and gears. They offer precise control and are generally durable.

- Solenoid-driven Actuators (Older or Simpler Systems): These use an electromagnetic coil (solenoid) to create a rapid, linear pulling or pushing motion. They are typically simpler but can be less robust for frequent use.

- Convenience: Allows for simultaneous locking or unlocking of all doors with a single action, eliminating the need to manually lock each door.

- Security: Ensures all doors are properly locked, preventing unauthorized access.

- Safety: Modern systems often include features like:

- Speed-sensitive locking: Doors automatically lock when the vehicle reaches a certain speed.

- Automatic re-locking: If you unlock the car but don't open a door within a certain time, the doors will re-lock automatically.

- Anti-theft features: Some systems disable interior release levers when "double locked" to prevent entry even after glass breakage.

- Remote Keyless Entry: Integral to the operation of key fob remotes.

- Inconsistent Locking/Unlocking: One or more doors don't respond reliably to the lock/unlock command from the fob or interior switch.

- Unusual Noises: Clicking, grinding, buzzing, or whirring sounds coming from inside the door when trying to lock or unlock. This often indicates worn gears or a struggling motor.

- Sluggish Operation: The door lock moves slowly or with a delay.

- Door Stays Locked or Unlocked: A specific door might be stuck in the locked or unlocked position, even when the rest of the car responds. You might still be able to operate it manually.

- Random Locking/Unlocking: The door might lock or unlock itself without input.

- "Door Ajar" Warning Light: In some cases, a faulty actuator (specifically, a worn internal switch) can cause the "door open" warning light to stay on even when the door is closed, or trigger the car alarm.

Siren

Ship or pick up from our office.

Siren

A siren is a noise-making warning device designed to produce a loud, often piercing or fluctuating sound to alert people to an emergency, an approaching threat, or to draw attention to a specific situation. Sirens are characterized by their ability to generate high sound pressure levels (decibels) that can be heard over long distances and through various obstacles. There are two main types of sirens:- Mechanical (or Pneumatic) Sirens:

- How they work: These sirens produce sound by physically chopping or interrupting a flow of air. They typically consist of a rotating disk (rotor) with holes or slots, which spins rapidly past fixed holes or slots on a stationary casing (stator). As the rotor spins, it alternately allows and blocks air to pass through, creating pulsating air pressure waves that we perceive as sound. The pitch of the siren changes with the speed of the rotor and the number of holes.

- Characteristics: Often produce a characteristic "wailing" or "growling" sound. They can be very loud and consume significant power.

- Uses: Traditionally used as large outdoor warning sirens (e.g., air-raid sirens, tornado sirens) and on older emergency vehicles. You might still hear them in some older industrial settings as well.

- Electronic Sirens:

- How they work: These are the most common type found in modern applications. They generate sound electronically using circuits like oscillators, modulators, and amplifiers. These circuits synthesize various siren tones, which are then played through powerful external speakers.

- Characteristics: Highly versatile, able to produce a wide range of distinct tones (e.g., Wail, Yelp, Phaser/Piercer, Hi-Lo, Air Horn, Manual), and can often include voice announcements. They are generally more compact, consume less power than large mechanical sirens, and are easier to control.

- Uses:

- Emergency Vehicles: Police cars, ambulances, fire engines, and other emergency response vehicles use electronic sirens to alert traffic and pedestrians to their presence and urgency. Different tones are often used for different situations (e.g., Wail for distant approach, Yelp for closer proximity or heavy traffic, Air Horn for immediate attention).

- Vehicle Alarms: Car alarms commonly use a smaller, electronic siren (or the vehicle's horn) to sound a loud alert when triggered by a sensor (like a shock sensor, door sensor, or ultrasonic sensor).

- Security Systems: Residential and commercial alarm systems use sirens to deter intruders and alert occupants and neighbors to a security breach.

- Industrial and Safety Alarms: Used in factories, construction sites, and other workplaces to signal shift changes, emergencies, or specific warnings.

- Civil Defense/Public Warning Systems: Modern outdoor warning systems often use large electronic sirens that can broadcast specific tones and even pre-recorded voice messages for events like severe weather, hazardous material spills, or other public safety alerts.

Remote starter immobilizer bypass module

Ship or pick up from our office.

Remote starter immobilizer bypass module

A remote starter immobilizer bypass module is an essential component when installing an aftermarket remote car starter in most modern vehicles. Its sole purpose is to "trick" the vehicle's factory immobilizer system into believing that the correct key is present in the ignition, allowing the engine to start remotely. Here's a breakdown of what that means: What is a remote starter immobilizer bypass module system? Since around the late 1990s, and mandated for all new cars sold in Canada since the year 2000, virtually every vehicle is equipped with an electronic immobilizer system as an anti-theft measure. This system prevents the engine from starting unless it detects a specific, valid code.- How it works:

- Your car key (or smart key fob) contains a small electronic chip called a transponder. This chip stores a unique electronic code.

- When you insert the key into the ignition (or, with push-button start, have the fob within range), the vehicle's onboard computer (often via an antenna coil around the ignition barrel) reads the code from the transponder.

- If the code matches what's stored in the vehicle's ECU (Engine Control Unit), the remote starter immobilizer bypass module is deactivated, and the engine is allowed to start and run.

- If the code doesn't match, or if no valid code is detected (e.g., someone tries to hot-wire the car, or uses an unprogrammed key), the immobilizer will prevent the engine from starting, or it will start for a few seconds and then immediately shut off. It typically disables vital functions like the fuel pump or ignition system.