Shop

Car remote starter – ProStart

Ship or pick up from our office.

Car remote starter - ProStart

ProStart is a brand of aftermarket car remote starters, primarily known for being sold at Canadian Tire in Canada. They offer systems that allow you to start your car remotely, typically using a key fob, for convenience and comfort, especially in climates with extreme temperatures. Here's a breakdown of what a ProStart car remote starter generally offers: Core Functionality:- Remote Engine Start: The primary feature, allowing you to start your vehicle from a distance. This is great for warming up your car in winter or cooling it down in summer before you even get in.

- Keyless Entry: Many ProStart systems integrate with your vehicle's door locks, allowing you to lock and unlock your doors using the remote.

- Trunk Release: Some models include a button for remotely opening your trunk.

- Compatibility: ProStart remote starters are designed to work with both manual and automatic transmissions, as well as gas and diesel engines. However, manual transmission vehicles typically require additional safety protocols to be enabled (like a "ready mode" that ensures the car is in neutral and the parking brake is engaged before remote starting).

- Range: Depending on the model, ProStart remotes can offer varying ranges, from a few hundred feet up to 1600 feet (490 meters) or more.

- Integrated Alarm System: Many ProStart kits come with a basic alarm system, including features like:

- Shock Sensor: Detects impacts and can trigger a warning chirp or full alarm.

- Siren and LED Notification: Visual and auditory alerts if the alarm is triggered.

- Starter Kill: Disables the vehicle's starter to prevent theft.

- Cold Weather Mode: Some systems can be programmed to automatically start the engine at intervals to maintain a comfortable temperature in extreme cold, helping to prevent battery drainage.

- Idle Mode: Allows the user to leave the vehicle running and protected while they step away (e.g., for a quick stop), with doors locked.

- Two-Way Communication: Higher-end models may offer two-way remotes that provide feedback from the vehicle (e.g., confirming the car started, locked, or if the alarm was triggered) via an LED or LCD screen on the remote.

- SmartStart Compatibility: Certain ProStart systems can be paired with a smartphone app (like iDatalink's SmartStart or similar) for remote control functions via your phone, offering unlimited range (as long as you have cellular service).

- Programmable Run Time: You can typically set how long the engine will run after a remote start (e.g., 10, 15, 20 minutes) before automatically shutting off.

- Interface Module Requirement: Most modern vehicles require an interface module (like the iDatalink ADS-TB discussed previously) to allow the remote starter to communicate with the vehicle's onboard computer and bypass the immobilizer system. This module is usually sold separately.

- Remote starters involve complex wiring and integration with your vehicle's electrical system. While some experienced DIYers might attempt it, professional installation by a certified technician is generally recommended to ensure proper function and avoid damage to your vehicle.

Car alarm system

Ship or pick up from our office.

Car alarm system

A car alarm system is an electronic device installed in a vehicle primarily to deter theft of the vehicle itself or its contents. It works by emitting a high-volume sound (often a siren, the car's horn, or a combination) and sometimes flashing the vehicle's lights when conditions for triggering it are met, alerting the owner and potentially scaring off thieves. How Car Alarm Systems Work: Car alarms generally consist of three main components working together:- Control Unit (Brain): This is the central processing unit of the alarm system. It receives signals from various sensors, processes them, and, if it detects unauthorized activity, triggers the alarm. It's essentially the "computer" that manages all the system's functions.

- Sensors: These are the "eyes and ears" of the alarm, constantly monitoring the vehicle for signs of intrusion or tampering. Common types of sensors include:

- Door/Trunk/Hood Sensors: These detect when a door, trunk, or hood is opened without authorization. They often work by detecting a change in an electrical circuit, similar to how your dome light turns on when a door is opened.

- Shock Sensors: These detect impacts or vibrations to the vehicle. A gentle bump might trigger a warning chirp, while a harder impact (like a window breaking or someone trying to tow the car) will trigger the full alarm.

- Glass Break Sensors: These specifically listen for the distinctive sound frequency of breaking glass.

- Motion/Proximity Sensors: These detect movement inside or outside the vehicle, often used in convertibles or vehicles with open interiors.

- Tilt Sensors: These detect if the vehicle is being tilted or lifted, such as during a towing attempt or when someone tries to jack up the car to steal wheels.

- Siren/Horn: This is the audible output of the alarm system. When triggered by the control unit, it emits a loud, piercing sound to draw attention and scare away intruders. Aftermarket sirens are often louder than a vehicle's factory horn.

- OEM (Factory-Installed) vs. Aftermarket:

- OEM alarms are built into the vehicle at the factory and typically offer basic features like monitoring doors, trunk, and ignition for unauthorized entry.

- Aftermarket alarms are installed after the car is built and can offer a much wider range of features, sensors, and customization options.

- Active vs. Passive Systems:

- Active alarms require the user to manually arm and disarm them (e.g., by pressing a button on a key fob).

- Passive alarms automatically arm themselves under certain conditions, such as when the car is locked, the engine is turned off, or the key fob moves out of range.

- One-Way vs. Two-Way Remotes:

- One-way remotes send commands to the car (lock, unlock, arm alarm) but don't receive feedback.

- Two-way remotes can send commands and also receive confirmation or alerts from the vehicle (e.g., "alarm triggered," "doors locked"). Some even have LCD screens displaying vehicle status.

- Integration with Other Security Features:

- Remote Start: Many modern alarm systems integrate with remote start functionality, allowing you to start your car from a distance while keeping it secure.

- Immobilizers: While distinct from alarms, many advanced security systems incorporate immobilizers, which prevent the engine from starting without the correct key or transponder, making hot-wiring virtually impossible.

- GPS Tracking: Some high-end systems include GPS tracking, allowing you to locate your vehicle in real-time if it's stolen and send alerts to your smartphone.

- Smartphone Integration: Many systems offer mobile apps that allow you to arm/disarm the alarm, check vehicle status, and receive alerts directly on your phone.

- Kill Switches: These can disable specific electrical circuits, making it difficult for a thief to start the engine.

Sliding gate operator gear

Ship or pick up from our office.

Sliding gate operator gear

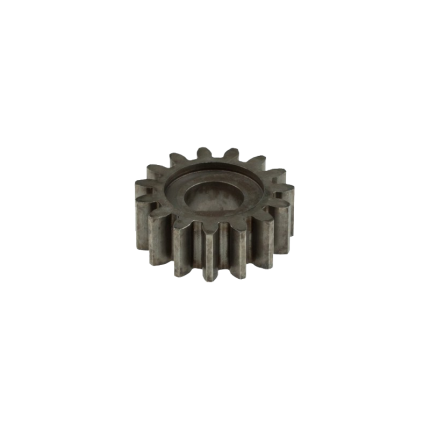

The sliding gate operator gear is a crucial component within an automatic sliding gate system. It's essentially the mechanism that translates the rotational power from the electric motor into the linear motion needed to open and close a sliding gate. Here's how it generally works:- Pinion Gear: Inside the gate operator's housing, there's a pinion gear. This is a small, typically round gear directly connected to the motor. When the motor turns, it rotates the pinion gear.

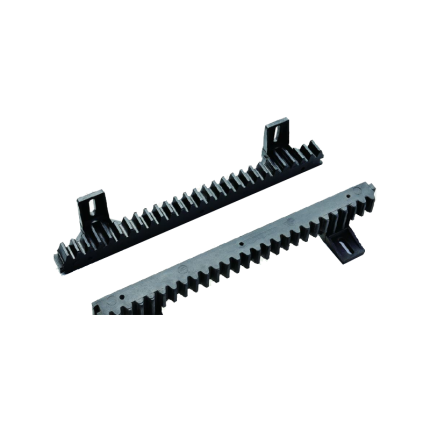

- Rack Gear: Attached to the bottom edge of the sliding gate itself is a rack gear. This is a long, straight bar with teeth that mesh with the teeth of the pinion gear.

- Translating Motion: As the motor spins the pinion gear, its teeth engage with the teeth on the rack gear. This engagement causes the rack gear (and thus the entire gate) to move horizontally along its track. It's similar to how a train moves along a toothed railway or a car's steering rack works.

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

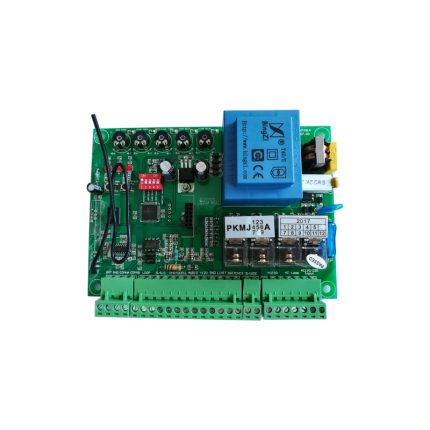

Swing gate operator control board SWRG110

Ship or pick up from our office.

Swing gate operator control board SWRG110

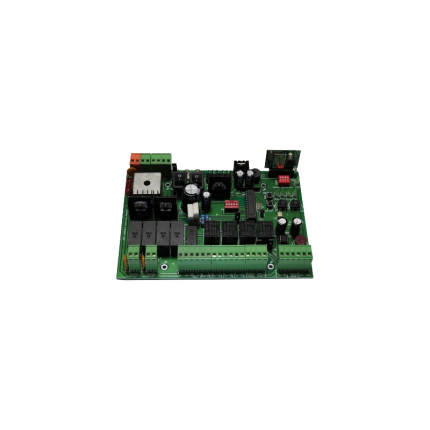

The SWRG110 is a universal swing gate operator control board designed to manage the operation of AC (Alternating Current) powered swing gate motors. It's essentially the "brain" of a swing gate automation system, responsible for controlling the gate's movement, safety features, and integration with various accessories. It's often marketed as a replacement or upgrade board due to its broad compatibility with different AC swing gate openers, particularly those operating at 110V or 220V. Key Features and Functionality The SWRG110, as a universal control board, typically offers a range of features for efficient and safe gate operation:- Motor Control: It manages the power supply and direction of one or two AC gate motors, allowing for opening and closing cycles. It can be used for both single and double swing gates.

- Soft Start/Stop: This feature ensures a smooth and gradual acceleration and deceleration of the gate, reducing wear and tear on the motor and mechanical components, and providing quieter operation.

- Obstacle Detection: A crucial safety feature, obstacle detection allows the gate to stop or reverse if it encounters an obstruction during its movement, preventing damage to the gate, vehicle, or injury to people or pets. This is often achieved through current sensing or external safety sensors like photocells.

- Automatic Close: This function allows the gate to automatically close after a set period of time, enhancing security and convenience.

- Limit Switches: The board interfaces with limit switches (often magnetic or mechanical) to define the full open and full closed positions of the gate, ensuring precise stopping.

- Remote Control Learning: It typically has a learning function to pair with wireless remote controls, allowing users to open and close the gate from a distance.

- Accessory Interfaces: The SWRG110 provides terminals for connecting various gate accessories, such as:

- Photocells/Infrared Sensors: For enhanced safety and obstacle detection.

- Warning Lights: To signal gate movement.

- Keypads/Intercoms: For controlled access.

- GSM Modules/Phone APP integration: Some versions may offer connectivity for remote control via smartphone.

- Wall Buttons: For manual operation from inside the property.

- Exit Wands/Vehicle Sensors: To automatically open the gate for exiting vehicles.

- Adjustable Settings: Many control boards like the SWRG110 offer adjustable parameters, such as:

- Motor power/force (especially for obstacle detection sensitivity).

- Slowdown speed.

- Automatic close timer.

- Working time for each motor.

- Diagnostic Display: Some models include an LED or LCD display for easier setup, programming, and troubleshooting of errors.

- AC Powered Motors: Specifically, 110V or 220V AC swing gate motors. It's not compatible with DC (12V or 24V) motors.

- Various Gate Opener Models: It can replace control boards in numerous existing swing gate openers, such as some ALEKO and Lockmaster models.

- Power Disconnection: Safely disconnecting power to the gate opener.

- Wiring: Connecting the motor, power supply, and accessories to the appropriate terminals on the SWRG110 board. Understanding terminal functions is crucial for correct wiring.

- Programming: Learning remote controls and adjusting settings (e.g., limit switch calibration, auto-close time) according to the specific gate and desired operation.

Swing gate operator control board SWRG24

Ship or pick up from our office.

Swing gate operator control board SWRG24

The SWRG24 is a universal 24V DC main control board for swing gate operators. This means it's designed to be adaptable and compatible with a wide variety of 24-volt direct current swing gate systems, rather than being specific to one brand or model. Here's a breakdown of its key features and functionalities: Key Features- 24V DC Operation: The SWRG24 operates on a 24-volt direct current power supply, which is common in many modern gate systems, especially those that might incorporate battery backup for operation during power outages.

- Universal Compatibility: It's designed to work with various swing gate openers and systems, offering versatility for different installations. This often means it can replace a damaged board in an existing system or be used as the control center for a custom gate setup.

- Programmable and Adjustable Settings: The board is fully programmable, allowing installers and users to customize various operational parameters. These often include:

- Resistance Sensitivity: Adjusts how much force the gate encounters before stopping or reversing, crucial for safety.

- Motor Working Time: Sets the maximum time the motor will run for opening or closing, preventing over-rotation or damage.

- Auto-Closing Time: Configures a delay after opening before the gate automatically closes, enhancing convenience and security.

- Motor Output Power: Allows for fine-tuning the motor's strength to suit the gate's weight and size.

- Soft Start/Stop: This feature typically provides a gradual acceleration and deceleration of the gate, reducing wear and tear on the motor and hardware, and providing smoother operation.

- Quick Close/Anti-Tailgate: Some models may include features to close the gate immediately after a vehicle passes, preventing unauthorized vehicles from following closely behind.

- Digital Display: Many SWRG24 boards feature a digital display (often a digital tube display), which simplifies the process of adjusting settings, troubleshooting, and monitoring the system's status.

- Compatibility with Accessories: It typically has terminals and inputs for connecting a range of safety and access control devices, such as:

- Photocells/Infrared Sensors: Essential safety devices that detect obstructions in the gate's path and prevent it from closing on people or objects.

- Loop Detectors: Used to detect vehicles approaching or exiting the gate, triggering opening or closing.

- Push Buttons/Keypads: For manual operation or coded access.

- Remote Controls: For wireless operation.

- Warning Lights/Alarms: For signaling gate movement or entrapment.

- Safety Compliance: Modern gate control boards like the SWRG24 are often designed to comply with safety standards like UL325, which requires the use of entrapment protection devices.

- Potential for Battery Backup: As a 24V DC system, it's often designed to integrate with battery backup systems, ensuring continued operation during power outages.

- Residential Gates: For homeowners seeking automated access and enhanced security.

- Commercial and Industrial Gates: For businesses and facilities with higher traffic demands, where reliable and secure access is critical.

Sliding gate operator control board SLRG110

Ship or pick up from our office.

Sliding gate operator control board SLRG110

The SLRG110 is a universal main control board for sliding gate operators that runs on 110-volt AC power.

It acts as the "brain" of a sliding gate system, managing its core functions.

Here's a breakdown of what the SLRG110 offers:

Core Functionality

- Motor Control: It receives signals from various access devices (like remote controls or keypads) and translates them into commands to control the gate's motor, initiating opening, closing, and stopping movements.

- Power Management: It receives power from a 110V AC source and directs it to the gate motor and other connected accessories.

- Adjustable Settings: The board typically allows for customization of gate operation, including:

- Adjustable speed settings for both opening and closing.

- Adjustable auto-close timer (e.g., 0, 30, 60, 90 seconds).

- Adjustable torque and closing force to suit different gate weights and preferences.

- Ability to add and delete remote controls easily.

- Option to set auto-close when power is restored after an outage.

Key Features & Safety

- Obstruction Detection: A crucial safety feature, the SLRG110 can detect obstructions in the gate's path during movement and automatically stop or reverse the gate to prevent damage or injury.

- This often utilizes infrared detection connectors for photocells.

- Remote Control Capability: It's designed to work seamlessly with remote controls for convenient operation.

- Emergency Release: The system usually includes an emergency release key for manual operation in case of power failure.

- Limit Switches: It connects to limit switches (often magnetic) that define the gate's fully open and closed positions, preventing overtravel.

- Accessory Inputs: The board has various input terminals for connecting additional accessories like:

- Photocells (safety beams)

- Manual push buttons

- Wired keypads

- GSM inputs (for remote access via mobile networks)

- Vehicle sensor exit wands

Universal Compatibility

The SLRG110 is considered a universal control board, meaning it's designed to be compatible with a wide range of sliding gate opener models.

This makes it a versatile replacement option for existing systems. It can operate gates weighing up to approximately 1750-1760 lbs.

Sliding gate opener -Royalgate RGSL0.5TN24

Ship or pick up from our office.

Sliding gate opener -Royalgate RGSL0.5TN24

*Suitable gate weight: Maximum 500 Kg Included: *1 x DC 24 Volts Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release key The Royalgate RGSL0.5TN24 is a sliding gate opener designed for automated operation of sliding gates. Here's a breakdown of its key features and specifications based on the information available:- Type: Sliding Gate Opener. This means it's for gates that move horizontally along a track, not swinging gates.

- Capacity: It's designed to handle gates with a maximum weight of 500 kg (approximately 1100 lbs).

- Motor: It's powered by a 24V DC electromechanical motor. DC motors are known for energy efficiency and are often suitable for battery backup and solar power options.

- Key Features:

- Automated Operation: Provides convenient opening and closing of your sliding gate.

- Emergency Release: Includes manual release keys for operation during power failures.

- Safety Mechanisms: Often includes features like soft start/stop (to reduce wear and tear) and auto-reverse (the gate reverses if it detects an obstruction).

- Adjustable Auto-Close: The system likely has a built-in timer for automatic closing of the gate (e.g., 0, 30, 60, 90 seconds).

- Reliable Limit Sensors: Uses spring limit sensors for easy adjustment of the gate's open and close positions.

- Expandability: Can be integrated with optional accessories such as keypads, additional remote controls, radio receivers, and safety sensors (like photocells).

- Applications: Commonly used for both residential and light commercial applications, such as driveways, parking areas, and small commercial properties.

- Construction: The control unit often features an air-stop seal against moisture and insects, and mechanical parts are typically lubricated with lithium grease for protection against corrosion.

Sliding Gate V-Track

Ship or pick up from our office.

Sliding Gate V-Track

NOTE: For 25 ft sliding gate V-Track, please do not make an online order.Because of the limit of the shipping length and weight, we have to cut the full length of the product (25') to 2 x (12'-6") for pick-up from our store OR 4 x (6'-3") to send by Canada Post.

If your order requires cutting services, additional costs will apply.

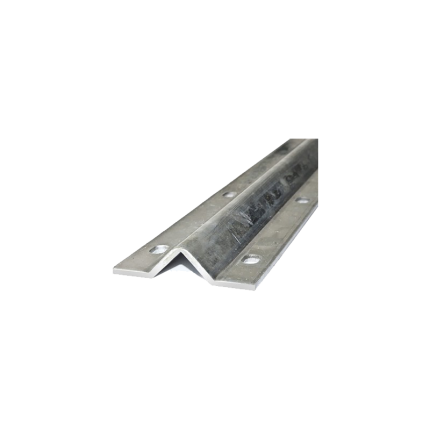

To create an order for sliding gate V-Track, please send your request with the shipping address, postal code, and the length of your inquiry in the note. You will receive a quotation with the shipping costs within a maximum of one business day. A sliding gate V-track is a specific type of ground track that a sliding gate rolls on, utilizing wheels with a complementary V-shaped groove. This system is one of the most common ways to implement a sliding driveway gate, especially for residential and light commercial applications. Here's a breakdown: Purpose: The sliding gate V-track as the linear guide and support for the entire sliding gate. It ensures that the gate moves in a straight line, smoothly, and without wobbling or derailing as it opens and closes. It's an integral part of a "rolling gate" system, where the gate literally rolls on the ground. Key Characteristics and Components:- V-Shape Profile: The most defining feature. The track has an inverted V-shape or a 90-degree angle (like an angle iron) with a slightly rounded top. This V-shape mates perfectly with the V-groove wheels attached to the bottom of the gate.

- Materials:

- Galvanized Steel (Most Common): Highly durable, strong, and resistant to corrosion due to the galvanization process. It can handle heavy gates and high traffic volumes. Sections are typically joined together to form the required length.

- Aluminum: Lighter weight and excellent corrosion resistance. Often used for lighter gates or in environments where rust is a major concern (like coastal areas).

- Installation:

- Bolt-Down: The V-track is typically designed to be bolted securely to a concrete driveway or foundation. It has pre-drilled holes for anchor bolts. This allows for easier installation on existing concrete and simpler replacement if a section gets damaged.

- Embeddable (Less Common for DIY): Some V-tracks are designed to be embedded directly into wet concrete during construction.

- Level and Straight: Crucially, the V-track must be installed perfectly level and straight along the entire travel path of the gate to ensure smooth and consistent operation. Any dips, humps, or curves will cause issues with the gate's movement and can put undue strain on the gate operator and wheels.

- Lengths: Sliding gate V-tracks are sold in sections (e.g., 6 feet, 10 feet, 2.4 meters, 3 meters). Multiple sections are joined together using connection pins or by welding to achieve the total required length, which should be at least twice the width of the gate opening to allow the gate to fully retract.

- Complementary Hardware:

- V-Groove Wheels: These are essential and roll directly on top of the V-track. As discussed previously, they have a V-shaped groove that fits snugly into the track.

- Guide Rollers/Posts: Used at the top of the gate to keep it upright and prevent tipping.

- Gate Stops: Installed at the ends of the track to prevent the gate from over-traveling.

- Stability: The sliding gate V-track V-groove design provides excellent lateral stability, keeping the gate aligned and preventing it from wobbling.

- Load Capacity: Due to the direct ground support and robust V-track/wheel combination, these systems can handle very heavy and long gates.

- Simple Mechanical Principle: The system is straightforward, making it reliable.

- Debris Accumulation: The main drawback is that the V-track, being on the ground, is susceptible to collecting dirt, leaves, gravel, snow, and ice. This debris can obstruct the gate's movement, cause wear on the wheels, and may even lead to derailment or damage to the gate opener. Regular cleaning of the track is essential, especially during winter months in Canada.

- Driveway Disruption: Installing a sliding gate V-track requires modifying the driveway surface, often by bolting it down or embedding it in concrete, which creates a slight raised profile.

- Water Drainage: Proper drainage around the track is important to prevent water pooling.

Universal sliding gate operator control board SLRG24

Ship or pick up from our office.

Universal sliding gate operator control board SLRG24

The Universal Sliding Gate Operator Control Board SLRG24 is the "brain" of an automatic sliding gate system. It's designed to be a versatile replacement or core component for various DC-powered sliding gate operators, meaning it can control a wide range of motors and integrate with different accessories. Here's a detailed look at its features and significance: Core Function of a Control Board: The control board is the central electronic unit that:- Receives Signals: Interprets commands from remote controls, keypads, safety sensors (photocells, shock sensors, loop detectors), intercom systems, and other access control devices.

- Processes Logic: Decides what action the gate should take based on the received signals and its programmed settings (e.g., open fully, partially open for pedestrian, close, stop, reverse due to obstruction).

- Activates Motor: Sends the appropriate electrical signals to the gate motor to start, stop, or reverse its movement.

- Manages Accessories: Controls the power and operation of connected safety and convenience accessories like flashing lights, electric locks, and alarm outputs.

- Universal Compatibility: This is its defining characteristic.

- DC Motor Compatibility: It's designed to work with both DC 12V and DC 24V motors. This flexibility is crucial as many sliding gate operators use one of these DC voltages. It's important to note that it is NOT compatible with AC (Alternating Current) motors (like 110V or 220V AC motors).

- Limit Switch Flexibility: It can work with both spring-type mechanical limit switches and magnetic limit switches. This is a significant advantage for a universal board, as it means it can be used with a wider range of existing gate operators.

- Input Power: The board itself typically requires an AC 24V input power. This means it likely has an internal transformer or is designed to be powered by an external AC 24V transformer.

- Full Programmability: Offers a wide range of adjustable parameters, allowing customization of gate operation to suit specific needs:

- Gate Speed: Adjustment of how fast the gate opens and closes.

- Opening/Closing Times: Setting precise durations for gate cycles.

- Automatic Closing Time: Programming a delay before the gate automatically closes after opening (e.g., 15, 30, 45 seconds, or up to 3 minutes).

- Safety Settings: Integration and management of safety sensors (photocells, obstacle detection sensitivity).

- Pedestrian Mode: Ability to set a partial opening for pedestrian access.

- Party Mode: Often allows for temporary cancellation of auto-close for periods when many visitors are expected.

- Remote Control Capability:

- Features an integrated radio receiver, typically operating at 433.92MHz with rolling code technology. Rolling code prevents unauthorized cloning of remote controls, enhancing security.

- Supports multiple remote controls (e.g., up to 20 or more), making it suitable for larger families or multi-user environments.

- Accessory Output Power: Provides DC 24V accessory output power (e.g., 200mA max) to power various external devices:

- Safety Sensors (Photocells): Connects to and powers safety beams.

- Warning Flash Lights: Powers a flashing beacon that activates when the gate is in motion.

- Keypads/Intercom Systems: Provides power and input connections for wired access control devices.

- Electric Locks: Can manage the operation of an electric lock for added security.

- Safety Mechanisms:

- Obstacle Detection: Uses current sensing or other methods to detect if the gate encounters an obstruction during movement. Upon detection, it will typically stop or reverse the gate for safety.

- Automatic Stop Function: Ensures the gate stops precisely at its programmed limits.

- Short Circuit Protection: Often includes protection for output circuits (e.g., lock output) to prevent damage from wiring faults.

- Solar System Input: The mention of "Input Solar system" suggests it's designed to be compatible with or directly connect to solar charging systems for off-grid gate installations, making it suitable for rural properties or areas without easy access to AC power.

- Installation and Durability:

- Designed for relatively easy installation.

- Built with robust components for long-lasting performance in various weather conditions, though it usually requires housing in a waterproof box (often included in a kit).

- Features an automatic power-off memory function, retaining settings after a power outage.

- Replacing a Faulty Board: If an existing 12V or 24V DC sliding gate operator has a non-functional control board, the SLRG24 could be a suitable and cost-effective replacement, reducing the need to replace the entire gate motor.

- New Custom Gate Systems: It provides a flexible "brain" for custom-built sliding gate systems where the motor and other components are chosen separately.

- Solar-Powered Gates: Its solar input capability is a definite advantage for properties in Surrey or surrounding areas that might prefer or require solar power for their gate.

Warning Flash Light

Ship or pick up from our office.

Warning Flash Light

A driveway gate warning flash light (also commonly called a flashing beacon or safety light) is a safety accessory for automatic driveway gates. Its primary purpose is to provide a clear visual signal to pedestrians, cyclists, and vehicles that the gate is in motion (opening or closing) or about to move. Why are they important? Automatic gates, especially large or fast-moving ones, can pose a safety hazard if their movement isn't clearly indicated. A warning flash light enhances safety by:- Alerting Pedestrians: People walking or cycling near the gate might not hear the gate opener motor, especially if there's ambient noise. A flashing light provides an immediate visual cue that the gate is active, encouraging them to stay clear.

- Warning Vehicles: Drivers approaching the driveway might not immediately notice a gate beginning to open or close, especially at night or in adverse weather conditions. The flashing light draws their attention to the gate's movement, preventing potential collisions.

- Visibility in Poor Conditions: In fog, rain, snow, or at night (all relevant for Surrey, BC's climate), the flashing light significantly improves the gate's visibility.

- Compliance with Safety Standards: While not always legally mandated for residential gates, many gate automation safety standards (and good practice) recommend or require warning lights, particularly for commercial or high-traffic gates. Installing one helps ensure a safer operation.

- Feedback to the User: For the gate owner, the flashing light also provides a visual confirmation that the gate has received the command and is indeed operating.

- Flashing Action: The light typically flashes intermittently (strobes) to maximize its attention-grabbing effect.

- Color: Most commonly amber (orange/yellow) or red, as these colors are universally recognized as warning signals.

- Power Source: Designed to be wired into the gate operator's control board. They typically operate on low voltage (e.g., 12V, 24V DC, or sometimes universal 12-265V AC/DC) provided by the gate opener's power supply.

- LED vs. Incandescent: Modern warning lights almost exclusively use LEDs (Light Emitting Diodes) because they are:

- More energy-efficient.

- Have a much longer lifespan.

- Are brighter and more visible than traditional incandescent bulbs.

- Weatherproof: As they are mounted outdoors, they are built to be weatherproof (e.g., IP54, IP65, or IP67 rated) to withstand rain, dust, and temperature variations.

- Integrated Antenna (Optional but common): Many modern warning lights include a built-in antenna for the gate's radio receiver. This can extend the range of remote controls, which is a practical dual function, especially for long driveways.

- Mounting: Designed for easy mounting on a post, wall, or the gate opener's column.

- Audible Alerts (Optional): Some advanced models may also include a small buzzer or chime to provide an audible warning in addition to the visual flash.

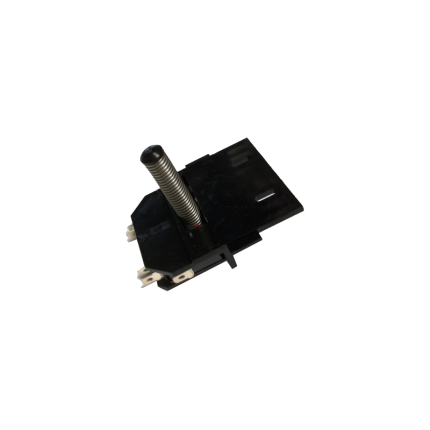

Sliding gate operator limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.