Shop

Radio receiver – LiftMaster 312HM

Ship or pick up from our office.

Radio receiver – LiftMaster 312HM

A LiftMaster radio receiver is a device that allows LiftMaster garage door openers, gate operators, and other access control systems to communicate wirelessly with remote controls or keypads. These receivers are crucial for enabling remote operation of devices and are often used in both residential and commercial settings.

Here's a more detailed explanation:

-

Functionality:LiftMaster radio receivers act as a bridge, translating the signals from a remote control or keypad into commands that the opener or operator can understand and execute.

-

Types:There are various types of LiftMaster receivers, including those designed for garage door openers, gate operators, and commercial door operators.

-

Security:Many LiftMaster receivers, especially those with Security+ 2.0 technology, use rolling code encryption to enhance security and prevent unauthorized access.

-

Compatibility:LiftMaster receivers are designed to be compatible with a range of LiftMaster remote controls and keypads.

-

Installation:Receivers can be internal (built into the opener or operator) or external (connected via wiring to the opener or operator).

-

Features:Some receivers offer features like multi-channel support (allowing control of multiple devices), narrow-band technology (to minimize interference), and the ability to temporarily disable remotes.

-

Examples:

- 850LM: A universal receiver compatible with Security+ 2.0 remotes, often used in gated communities and for controlling multiple access points.

- 412HM: A 390MHz Liftmaster radio receiver commonly used with gate operators and commercial doors.

- STAR1000: A commercial receiver with advanced features like user management and copying remote settings.

- 850LM: A universal receiver compatible with Security+ 2.0 remotes, often used in gated communities and for controlling multiple access points.

Radio receiver – LiftMaster 412HM

Ship or pick up from our office.

Radio receiver – LiftMaster 412HM

How it Works:

- The receiver is installed on the gate or garage door opener's control board.

- It receives signals from the remote control.

- The receiver then transmits the signal to the opener's control board.

- The control board verifies the signal and activates the door or gate.

In essence, the 412HM allows you to control your gate or garage door with a LiftMaster remote, offering a secure and convenient access solution.

Sliding gate operator limit sensor – Magnetic mechanism

Ship or pick up from our office.

Sliding gate operator limit sensor - Magnetic mechanism

A sliding gate operator limit sensor, often a limit switch, is a crucial component that signals the gate operator when the gate has reached its fully open or fully closed position, stopping the motor and preventing over-travel. These sensors ensure the gate stops at the correct positions, preventing damage to the gate and surrounding structure.

Here's a more detailed explanation:

-

Function:Limit sensors, like limit switches, detect when the gate reaches its extreme open or closed positions.

-

How it works:When the gate reaches the limit, the sensor sends a signal to the gate operator's control board, which then stops the motor.

-

Importance:Without limit sensors, the gate might continue to move, potentially hitting the end posts or other obstructions, causing damage.

-

Types:Common types include magnetic limit switches and photoelectric sensors (photo eyes).

-

Magnetic Limit Switches:These utilize magnets placed on the gate and a magnetic sensor on the operator. When the magnet aligns with the sensor, it triggers the limit switch.

-

Photoelectric Sensors (Photo Eyes):These use infrared beams to detect obstructions. When the beam is broken (e.g., by the gate), the sensor signals the operator to stop.

-

Installation:Proper installation and adjustment of limit sensors are crucial for the reliable operation.

-

Maintenance:Regular inspection and maintenance of limit sensors are recommended, as they can wear out or become misaligned over time.

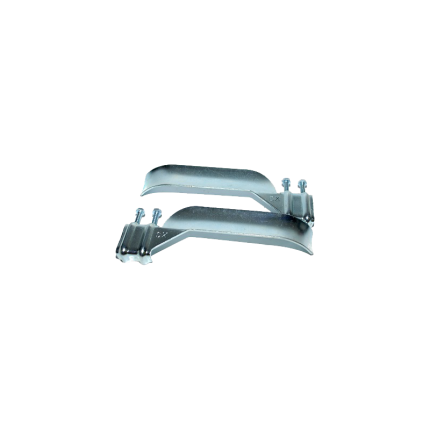

Sliding gate operator limit stopper bracket

Ship or pick up from our office.

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment. A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions. These limit stopper brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track. Here's a more detailed explanation: Purpose: The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling. How it works: The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor. Components: Bracket: The physical structure that holds the sensor. Sensor: A device (often a magnet) that interacts with the limit switch. Limit Switch: A switch on the gate operator's control board that is activated by the sensor. Importance: Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury. Reliability: Ensures consistent and reliable gate operation by defining the travel limits. Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.Sliding gate operator limit stopper bracket

Ship or pick up from our office.

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment.A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions.

These brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track.

Here's a more detailed explanation:

-

Purpose:The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling.

-

How it works:The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor.

-

Components:

- Bracket: The physical structure that holds the sensor.

- Sensor: A device (often a magnet) that interacts with the limit switch.

- Limit Switch: A switch on the gate operator's control board that is activated by the sensor.

- Bracket: The physical structure that holds the sensor.

-

Importance:

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

- Reliability: Ensures consistent and reliable gate operation by defining the travel limits.

- Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

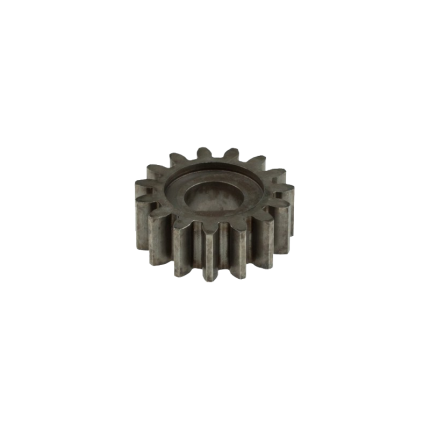

Sliding gate operator gear

Ship or pick up from our office.

Sliding gate operator gear

A sliding gate operator gear refers to the toothed gear or rack and pinion system that facilitates the movement of a sliding gate.

This system typically consists of a toothed metal bar (the rack) attached to the gate and a motorized pinion gear that engages with the rack, causing the gate to slide open and closed.

Here's a more detailed explanation:

-

Rack:This is a toothed bar, usually made of steel or nylon-reinforced steel, mounted along the bottom of the sliding gate.

-

Pinion Gear:This gear is connected to the motor of the gate operator. When the motor rotates, the pinion gear engages with the rack's teeth, causing the gate to move.

-

Operation:The rotation of the pinion gear drives the gate along the track, either opening or closing it, depending on the direction of rotation.

-

Materials:While some racks are made of all-metal, nylon racks with a steel core are popular due to their lightweight nature, durability, and resistance to rust and wear.

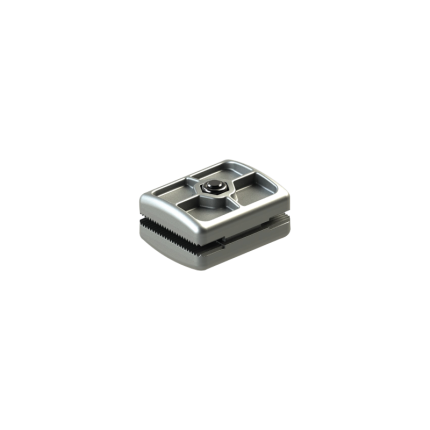

Swing gate operator -Physical stopper

Ship or pick up from our office.

Swing gate operator -Physical stopper

The swing gate opener physical stopper part that is located inside the gear-type swing gate operators. The swing gate operator physical stopper is adjustable, and it sets limits in the closing and opening cycle; it is set by the driveway gate opener's technician. The compatible swing gate openers are: *NICE *VDS *Key AutomationManual release key – Swing/Sliding gate openers

Ship or pick up from our office.

Manual release key – Swing/Sliding gate openers

A swing or sliding gate opener release key is a tool that allows you to manually operate a swing gate when the automatic opener is not functioning, such as during a power outage. It disengages the automatic mechanism, enabling the gate to be opened or closed manually.

Here's a more detailed explanation:

-

Purpose:The key is used to unlock the gate opener's motor, allowing it to be moved by hand.

-

Location:The release mechanism is often found near the gate motor, either on the motor itself or in a nearby housing.

-

Functionality:The key may turn a dial or lever that releases the motor's gears, enabling manual operation.

-

Importance:This manual release mechanism is essential for emergency access and situations where the automatic system is unavailable.

Manual release key – Swing/Sliding gate openers

Ship or pick up from our office.

Manual release key – Swing/Sliding gate openers

All types of sliding gate openers and swing gate operators have a manual release key to get the driveway gate operator into the manual mode. The manual release key shape and type are different, and depend on the brand and model of the driveway gate opener. To release a swing gate opener or sliding gate operator in emergency times when the driveway gate is closed, the gate operator is not working, and not opening the gate for any reason, the resident needs to open the gate using the release key.Gate operator capacitor

Ship or pick up from our office.

Gate operator capacitor

A gate operator capacitor is an electrical component that assists the motor in a gate opener system to start and run smoothly.

It stores and releases electrical energy to provide the initial torque needed to get the motor going and to ensure consistent operation. These capacitors are crucial for both swing and sliding gate openers that are powered by AC.

Here's a more detailed explanation:

-

Starting the Motor:When a gate opener is activated, the motor needs a significant amount of power to begin rotating. The capacitor provides a burst of electrical energy to help the motor overcome its inertia and start moving.

-

Maintaining Smooth Operation:Once the motor is running, the capacitor helps to smooth out the electrical current, ensuring consistent and efficient operation. This prevents the motor from stalling or experiencing performance issues due to voltage fluctuations.

-

Types of Capacitors:Gate operator capacitors can be categorized as either start capacitors or run capacitors.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

- Run capacitors: help to maintain consistent motor performance during operation.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

-

Common Applications:Capacitors are used in various gate operator systems, including:

- Swing gate openers

- Sliding gate openers

- Commercial and residential gate systems

- Barrier arms

- Overhead doors

- Swing gate openers

-

Compatibility:Different gate operators may require specific types and sizes of capacitors, so it's important to choose the right replacement capacitor for your system.

Gate operator capacitor

Ship or pick up from our office.

Gate operator capacitor

A gate operator capacitor is an electrical component that assists the motor in a gate opener system to start and run smoothly.

It stores and releases electrical energy to provide the initial torque needed to get the motor going and to ensure consistent operation. These capacitors are crucial for both swing and sliding gate openers that are powered by AC.

Here's a more detailed explanation:

-

Starting the Motor:When a gate opener is activated, the motor needs a significant amount of power to begin rotating. The capacitor provides a burst of electrical energy to help the motor overcome its inertia and start moving.

-

Maintaining Smooth Operation:Once the motor is running, the capacitor helps to smooth out the electrical current, ensuring consistent and efficient operation. This prevents the motor from stalling or experiencing performance issues due to voltage fluctuations.

-

Types of Capacitors:Gate operator capacitors can be categorized as either start capacitors or run capacitors.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

- Run capacitors: help to maintain consistent motor performance during operation.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

-

Common Applications:Capacitors are used in various gate operator systems, including:

- Swing gate openers

- Sliding gate openers

- Commercial and residential gate systems

- Barrier arms

- Overhead doors

- Swing gate openers

-

Compatibility:Different gate operators may require specific types and sizes of capacitors, so it's important to choose the right replacement capacitor for your system.