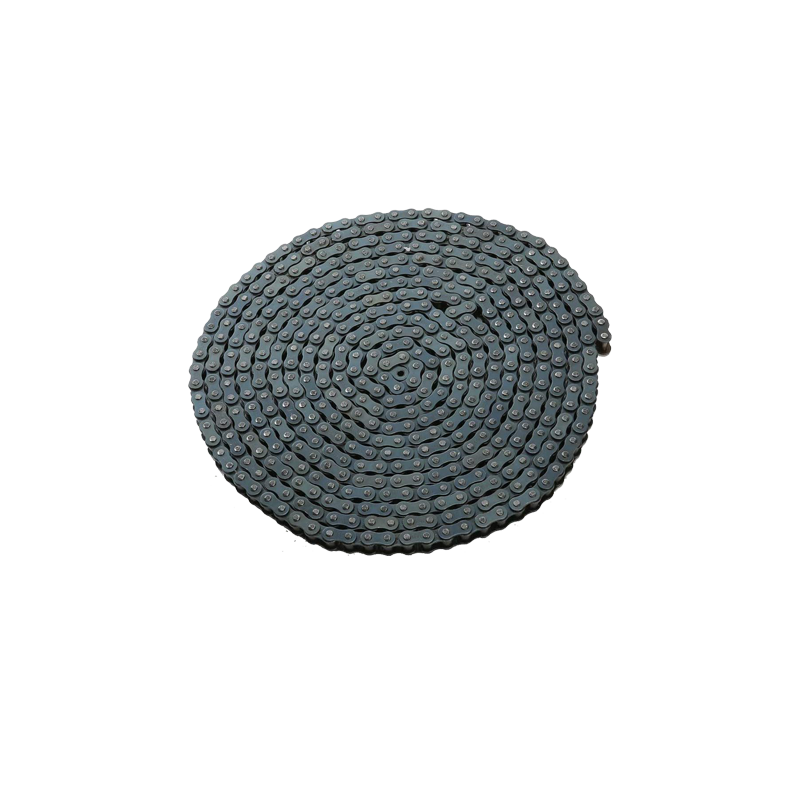

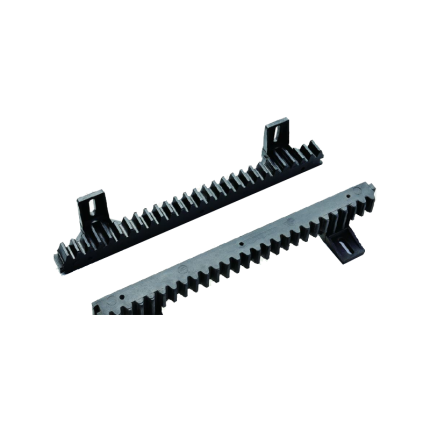

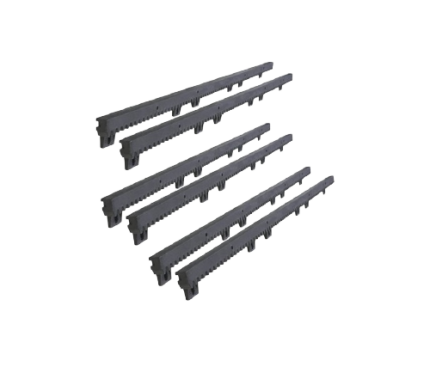

Sliding gate operator chain

*Length: 10 Feet

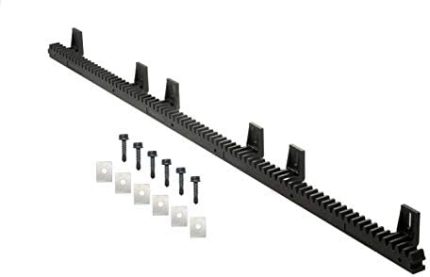

It acts as the mechanical link between the motor’s drive system and the gate, facilitating the gate’s horizontal movement along a track.

-

Power Transmission:

The chain transmits the rotational force from the gate operator’s motor to the gate, converting the motor’s power into linear motion to move the gate.

-

Smooth Operation:

The chain’s design (pitch, roller diameter, etc.) is optimized for smooth and consistent gate movement, minimizing friction and noise.

-

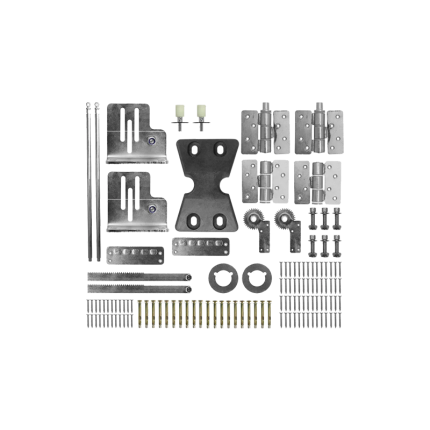

Durability:

The chain needs to be strong enough to withstand the weight and forces involved in moving the gate, especially in heavier-duty applications.

-

Chain Size/Type:

#40 and #41 roller chains are commonly used in sliding gate operators, with #40 being more prevalent.

-

Pitch:

The distance between the rollers on the chain (e.g., 0.5 inches for #40 and #41) impacts how smoothly the chain moves and meshes with the sprockets.

-

Tensile Strength:

The chain’s ability to withstand pulling or stretching forces is crucial for its longevity and reliable operation.

-

Installation:

The chain is attached to both the gate and the operator mechanism, often using brackets and idler sprockets to guide its path.

-

Tensioning:

Chains may require tensioners to ensure they are taut enough for proper operation without being too tight.

-

Lubrication:

Regularly lubricating the chain with appropriate lubricants can reduce friction and wear, extending its lifespan.

Reviews

There are no reviews yet.