Ship or pick up from our office.

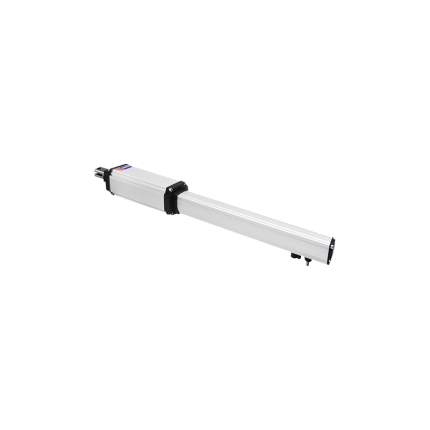

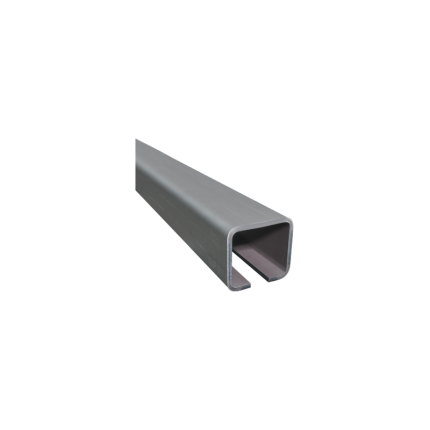

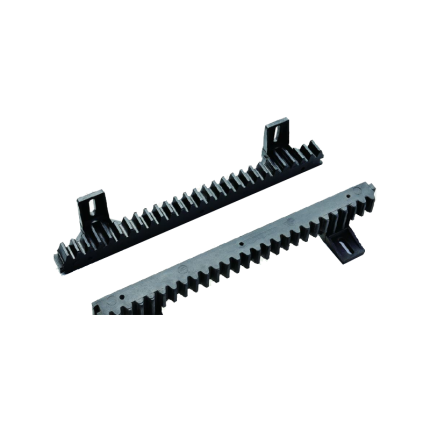

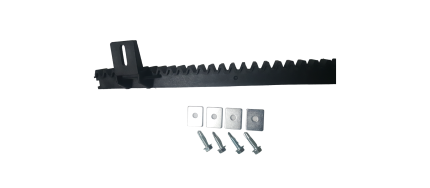

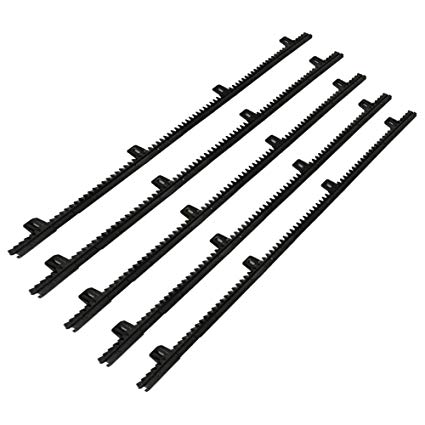

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate.

Let's break down what SLGR2 likely refers to and its characteristics:

Function of a Gear Rack:

- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

Key Features of the SLGR2 Gear Rack:

Based on the search results, particularly from Royal Gate (which operates in Surrey, BC):

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

Where you'd use it:

The

Sliding Gate Operator Gear Rack SLGR2 is used in conjunction with

gear rack sliding gate operators. These are the most common type of automatic opener for sliding gates, where the gate itself has wheels that run on a ground track (as opposed to cantilever gates).

In the context of Vancouver, BC:

If you are looking for parts for a sliding gate operator system in Canada, Royal Gate is a local supplier that specifically lists the SLGR2 gear rack. This means it's a standard replacement part or component they offer for their range of sliding gate operators. When purchasing, it's crucial to ensure the SLGR2 (or any gear rack) is compatible with the "module" of your existing gate operator's pinion gear for proper meshing and operation.

Reviews

There are no reviews yet.