Sliding gate opener

Gate Opener Remote Control 1400FT315

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315

*High-Range 1400ft *315 MHz *Compatible with HomeLink system on vehicles *1 channelSliding Gate Opener -Zero ZSL1000

Ship or pick up from our office.

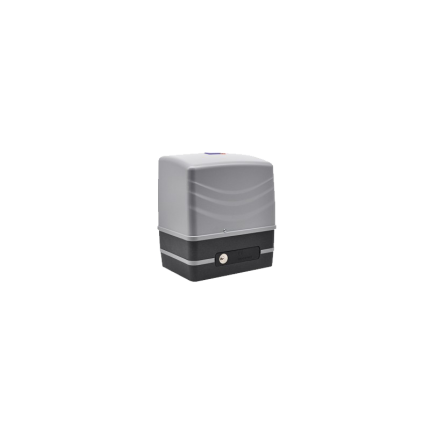

Sliding Gate Opener -Zero ZSL1000

*Suitable gate weight: Maximum 1000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release keySliding gate opener – VDS Carrera SL800

Ship or pick up from our office.

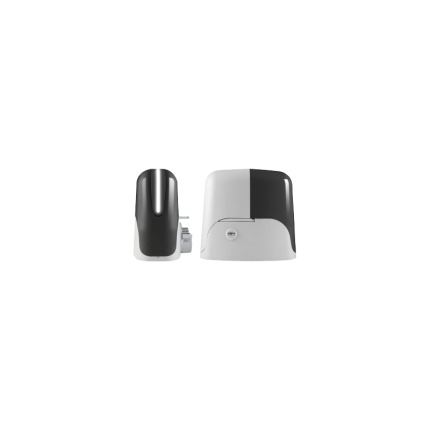

Sliding gate opener - VDS Carrera SL800

Suitable gate weight: Maximum 800 Kg Included:- 1 x Electromechanical motor

- 1 x Main control board

- 4 Meters x SLGR41 Gear rack

- 2 x Remote control

- 2 x Manual release key

- 1 x Base Plate

- 2 x Limit Switch bracket

- Installation Manual

- Programming Manual

Key Features of the VDS Carrera Gate Openers:

-

Sliding Gate Compatibility:The Carrera series is designed for sliding gates, utilizing a gear rack-driven mechanism.

-

Weight Capacity:Models are available for gates weighing up to 800 kg (Carrera 800) and 1000 kg (Carrera 1000).

-

Robust Construction:The motors feature steel and cast iron gears, lubricated with lithium grease for corrosion resistance and quiet operation, according to VDS Automation.

-

Control and Safety:They include a control unit with an air-stop seal, anti-squashing system, and options for electronic torque control and slowing down.

-

Easy Programming:The pre-wired systems are designed for easy programming and installation.

-

Optional Accessories:Keypads, remote control radio receivers, and safety sensors can be integrated.

-

Made in Italy:VDS Automazioni is an Italian company that emphasizes the quality and safety of its products.

-

Manual Release:A manual release lever with a custom key is included for emergency situations.

Sliding gate opener -VDS Carrera SL1000

Ship or pick up from our office.

Product Sheet PDF

Sliding gate opener -VDS Carrera SL1000

*Suitable gate weight: Maximum 1000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release key *1 x Base Plate *2 x Limit Switch bracket *Installation Manual *Programming ManualSliding gate opener -Key Automation TURBO82120

Ship or pick up from our office.

Product Sheet PDFSliding gate opener -Key Automation TURBO82120

Included in the Package:

- 1 x Electromechanical motor

- 1 x Main control board

- 4 Meters x SLGR41 Gear rack

- 2 x Remote control

- 2 x Manual release key

TECHNICAL FEATURES

| Speed | cm/s | 16 |

| Torque | Nm | 23 |

| Duty cycle percentage | % | 30 |

| Control unit | CT102B | |

| Voltage | Vac | 120 |

| AC Voltage Frequency | Hz | 50/60 |

| Nominal current | A | 1,9 |

| Nominal power | W | 450 |

| Appliance isolation class | I | |

| Degree of protection | IP | 44 |

| Dimensions (L - D - H) | mm | 320 - 184 - 260 |

| Item | kg | 13 |

| Minimum operating temperature | °C | -20 |

| Max operating temperature | °C | +55 |

| Max leaf weight | kg | 800 |

Sliding gate opener -Key Automation SUN7224

Ship or pick up from our office.

Product Sheet PDFSliding gate opener -Key Automation SUN7224

Electromechanical gear motor for sliding gates up to 700 kg:

- With a slowdown function both in opening and closing to preserve gate integrity

- Electronic and mechanical parts are well protected from external agents

- Easy maintenance thanks to the horizontal control unit position

- High technological materials resistant to weather conditions

- Gear reduction with an extra-large bearing with high performance

- Extremely silent mechanics, protected by a robust die-cast and powder-coated aluminum body

- With 24 Vdc control unit CT10224

- The release system is ergonomic, efficient, and easily accessible

- Opens gates weighing up to 700 kg

- Easy to install and programming

- Get the desired torque and tension by adjusting the parameters

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate opener –Key Automation SUN11024

Ship or pick up from our office.

Product Sheet PDFSliding gate opener –Key Automation SUN11024

High-quality Italian-made with state-of-the-art technology and design. Open gates weighing up to 1100 KG effortlessly with this gear rack-driven sliding gate opener. It is designed with a 24V DC motor, which provides exceptional torque, and its continuous operation makes it ideal for most applications. A 13 ft nylon gear rack track is included in the kit, and if your gates are more than 13 ft in length, then you can opt for an extra rack.- Opens gates weighing up to 1100 kg

- Easy to install and program

- Get the desired torque and tension by adjusting the parameters using the KUBE PRO and PROGRAMMING MODULE

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate operator limit sensor – Magnetic mechanism

Ship or pick up from our office.

Sliding gate operator limit sensor - Magnetic mechanism

A sliding gate operator limit sensor, often a limit switch, is a crucial component that signals the gate operator when the gate has reached its fully open or fully closed position, stopping the motor and preventing over-travel. These sensors ensure the gate stops at the correct positions, preventing damage to the gate and surrounding structure.

Here's a more detailed explanation:

-

Function:Limit sensors, like limit switches, detect when the gate reaches its extreme open or closed positions.

-

How it works:When the gate reaches the limit, the sensor sends a signal to the gate operator's control board, which then stops the motor.

-

Importance:Without limit sensors, the gate might continue to move, potentially hitting the end posts or other obstructions, causing damage.

-

Types:Common types include magnetic limit switches and photoelectric sensors (photo eyes).

-

Magnetic Limit Switches:These utilize magnets placed on the gate and a magnetic sensor on the operator. When the magnet aligns with the sensor, it triggers the limit switch.

-

Photoelectric Sensors (Photo Eyes):These use infrared beams to detect obstructions. When the beam is broken (e.g., by the gate), the sensor signals the operator to stop.

-

Installation:Proper installation and adjustment of limit sensors are crucial for the reliable operation.

-

Maintenance:Regular inspection and maintenance of limit sensors are recommended, as they can wear out or become misaligned over time.

Sliding gate operator limit stopper bracket

Ship or pick up from our office.

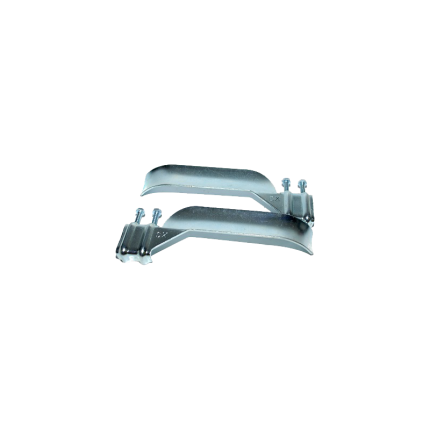

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment.A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions.

These brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track.

Here's a more detailed explanation:

-

Purpose:The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling.

-

How it works:The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor.

-

Components:

- Bracket: The physical structure that holds the sensor.

- Sensor: A device (often a magnet) that interacts with the limit switch.

- Limit Switch: A switch on the gate operator's control board that is activated by the sensor.

- Bracket: The physical structure that holds the sensor.

-

Importance:

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

- Reliability: Ensures consistent and reliable gate operation by defining the travel limits.

- Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

Sliding gate operator gear

Ship or pick up from our office.

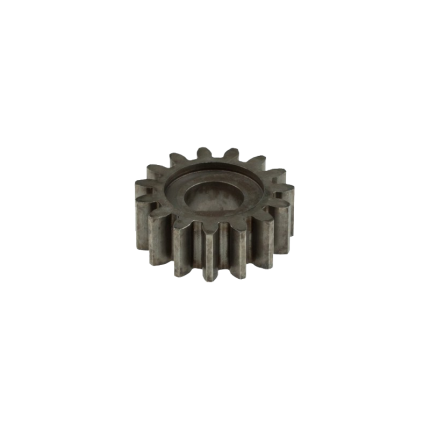

Sliding gate operator gear

A sliding gate operator gear refers to the toothed gear or rack and pinion system that facilitates the movement of a sliding gate.

This system typically consists of a toothed metal bar (the rack) attached to the gate and a motorized pinion gear that engages with the rack, causing the gate to slide open and closed.

Here's a more detailed explanation:

-

Rack:This is a toothed bar, usually made of steel or nylon-reinforced steel, mounted along the bottom of the sliding gate.

-

Pinion Gear:This gear is connected to the motor of the gate operator. When the motor rotates, the pinion gear engages with the rack's teeth, causing the gate to move.

-

Operation:The rotation of the pinion gear drives the gate along the track, either opening or closing it, depending on the direction of rotation.

-

Materials:While some racks are made of all-metal, nylon racks with a steel core are popular due to their lightweight nature, durability, and resistance to rust and wear.

Sliding gate operator main control board – Key Automation

Ship or pick up from our office.

Sliding gate operator main control board – Key Automation

The main control board for a Key Automation sliding gate operator, like the SUN7224 or SUN11024, is the central processing unit that manages the gate's movement, safety features, and other functionalities.

It receives signals from remote controls, keypads, or sensors, and then directs the motor to open or close the gate accordingly.

Here's a more detailed explanation:

-

Core Function:The control board acts as the "brain" of the gate system, interpreting signals and controlling the motor.

-

Input:It receives signals from various input devices, such as remote controls, keypads, or safety sensors.

-

Output:It sends commands to the motor to start, stop, reverse, or adjust its speed based on the input received.

-

Safety Features:Many control boards include safety features like obstacle detection, which can automatically stop or reverse the gate if it encounters an obstruction.

-

Programming and Diagnostics:Some control boards offer programming capabilities and diagnostic displays to simplify setup and troubleshooting.

-

D-Track Technology:Some Key Automation models, like the Deimos, utilize D-Track technology for precise torque management and impact detection.

-

Power Supply:Control boards typically operate on a specific voltage (e.g., 24V DC or 110V AC).