Shop

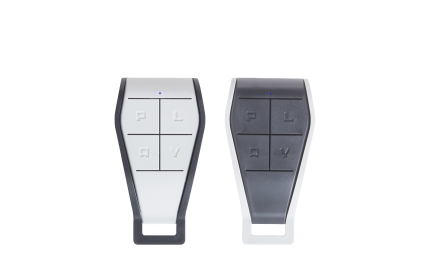

Original Gate Opener Remote Control

Ship or pick up from our office.

Original Gate Opener Remote Control

*433 MHz *2-4 Buttons *(More than 10 different designs)A gate opener remote is a handheld device that allows you to remotely open and close an automatic gate.

It sends a radio signal to a receiver connected to the gate's motor, triggering the gate to move. These remotes are a convenient way to control access to properties, especially when entering or exiting with a vehicle.

Here's a more detailed explanation:

-

Function:The remote transmits a radio signal to a receiver unit connected to the gate opener motor.

-

Convenience:They eliminate the need to manually open or close the gate, providing convenience and security.

-

Compatibility:Remotes must be compatible with the gate opener's frequency and coding system.

-

Types:There are various types of remotes, including single-button (for basic open/close) and multi-button (for more complex functions like stopping or partially opening the gate).

-

Programming:Remotes need to be programmed to work with the specific gate opener.

-

Frequency:Most gate openers use 433.92 MHz frequency, but some older systems might use different frequencies.

-

Range:The range of the remote can vary depending on obstructions like trees or buildings.

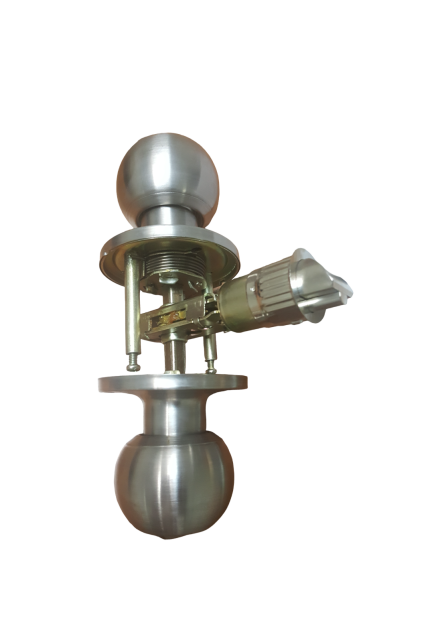

Pedestrian gate electric lock

Ship or pick up from our office.

Pedestrian gate electric lock

*DC12 V A pedestrian gate electric lock is a device that uses electrical power to secure a walk-through gate, offering enhanced security and convenience compared to traditional manual locks. These locks are commonly used in residential, commercial, and community settings, often integrated with access control systems. Here's a breakdown of what they are and how they work: How they work:- Electronic Control: The locking mechanism is controlled electronically. This allows it to be locked and unlocked automatically, typically triggered by an access control system.

- Access Control Integration: They can be linked to various access control devices, such as:

- Keypads: Users enter a code to unlock the gate.

- Remote controls: Wireless remotes allow for convenient opening from a distance.

- Intercoms: Visitors can communicate with occupants, who can then grant access.

- Key fobs/Card readers: Users can simply tap or swipe a fob/card to unlock.

- Push buttons: For easy exit from the inside.

- Telephone entry systems: Allowing access via phone.

- Types of Electric Locks:

- Electromechanical Locks: These use an electric impulse to trigger a mechanical latch or bolt to engage or disengage. They are known for their strength and durability, suitable for both indoor and outdoor use.

- Electromagnetic Locks (Maglocks): These consist of an electromagnet mounted on the gate frame and a strike plate on the gate itself. When power is applied, the electromagnet creates a strong magnetic force that holds the gate closed. To unlock, the power to the magnet is simply cut. They offer a high holding force and have no moving parts to wear out.

- Enhanced Security: They provide a higher level of security than manual locks, preventing forced entry and ensuring the gate remains closed, especially in high-wind conditions.

- Automatic Locking/Unlocking: Many models automatically lock when the gate closes and unlock when activated, eliminating the need for manual locking.

- Convenience: Remote operation, keypads, and other access control options make entry and exit much more convenient.

- Versatile Applications: Suitable for a variety of pedestrian gate types (wood, steel, vinyl, etc.) and environments, including driveways, pool areas, playgrounds, and commercial perimeters.

- Fail-Secure vs. Fail-Safe:

- Fail-Secure: The lock remains locked when power is lost. This is common for high-security applications where maintaining security during a power outage is crucial.

- Fail-Safe: The lock unlocks when power is lost. This is often used in safety applications where immediate access is needed during emergencies or power failures.

- Battery Backup: Many systems include a battery backup to ensure continued operation during power outages.

- Manual Override: Most electric locks come with a key for manual release, providing a backup in case of power failure or system malfunction.

- Integration: They can be easily integrated with existing gate openers, timers, and other smart home or security systems.

Pedestrian gate electric lock with 2 Remote controls

Ship or pick up from our office.

Pedestrian gate electric lock with 2 Remote controls

*DC 12 VPedestrian Gate Hinges

Ship or pick up from our office.

Pedestrian Gate Hinges

Pedestrian gate hinges are designed to allow a gate intended for pedestrian use to swing open and closed, connecting the gate to its post or frame.

These hinges are crucial for the smooth operation and secure closure of the gate, ensuring proper alignment and functionality. They can be surface-mounted, bolt-on, or weld-on, and may include features like spring-assist or adjustable tension for self-closing.

Here's a more detailed breakdown:

-

Function:Pedestrian gate hinges primarily serve to join the gate to its supporting structure (post or frame) and allow for rotation.

-

Types:They can be surface-mounted, bolt-on, or weld-on, offering different installation methods.

-

Features:Some hinges incorporate self-closing mechanisms, like spring-assist or adjustable tension, which can be important for safety or convenience.

-

Materials:They are commonly made from steel, stainless steel, or polymer, ensuring durability and resistance to the elements.

-

Applications:Pedestrian gate hinges are suitable for various settings, including residential, HOA, and commercial properties, especially for side gates, walkways, and restricted access enclosures.

-

Considerations:When choosing hinges, factors like the gate's weight, size, and desired functionality (e.g., self-closing) should be taken into account.

Pedestrian gate manual lock (One side key)

Ship or pick up from our office.

Pedestrian gate manual lock (One side key)

A "pedestrian gate manual lock (one side key)" refers to a type of locking mechanism for a gate that is operated manually and requires a key to unlock it from one side, while the other side allows for easy exit without a key. Here's a breakdown of its key features:- Manual Operation: This lock doesn't rely on electricity or automation. You physically use your hand to engage or disengage the locking mechanism.

- One-Sided Key Access: The defining characteristic is that a physical key is needed to unlock the gate from one specific side (usually the exterior or entry side).

- Easy Exit (Thumb-Turn, Latch, or Push Pad): On the interior or exit side, there's typically a simple mechanism like a thumb-turn, lever, push pad, or a basic latch that allows for quick and easy opening without needing a key. This is often a safety feature, especially for emergency exits.

- Security: It provides a basic level of security, preventing unauthorized entry from the keyed side.

- Power Independence: Since it's manual, it's not affected by power outages.

- Common Use Cases: These locks are frequently found on garden gates, backyard gates, pool gates, and other pedestrian access points where controlled entry is desired but a quick exit is also necessary.

Pedestrian gate manual lock (Two-sided key)

Ship or pick up from our office.

Pedestrian gate manual lock (Two-sided key)

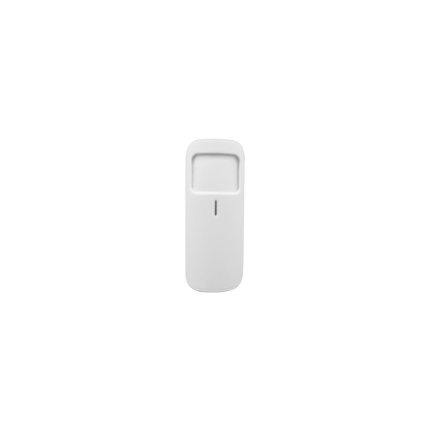

PIR Infrared Sensor – wired

Ship or pick up from our office.

PIR Infrared Sensor – wired

A PIR (Passive Infrared) sensor is an electronic sensor that detects infrared (IR) light radiating from objects within its field of view. It's called "passive" because it doesn't emit any energy itself; instead, it passively monitors the existing infrared radiation in its surroundings. All objects with a temperature above absolute zero emit some level of infrared radiation, and the hotter an object, the more radiation it emits. PIR sensors are particularly effective at detecting the infrared radiation emitted by warm bodies, such as humans and animals. How PIR Sensors Work At the core of a PIR sensor is a pyroelectric sensor, a material that generates an electrical charge when exposed to changes in infrared radiation. To detect motion, most PIR sensors use a dual-sensor design:- Dual Elements: The pyroelectric sensor is typically divided into two halves or elements, wired in a way that they cancel each other out when no motion is detected. This means that if both halves receive the same amount of IR radiation (e.g., from the ambient room temperature), their signals balance, and no output is generated.

- Fresnel Lens: A Fresnel lens is often placed in front of the pyroelectric sensor. This special lens has multiple facets that help to focus infrared light from different angles onto the sensor elements, increasing its range and sensitivity, and creating distinct detection zones.

- Motion Detection: When a warm object, like a person, moves across the sensor's field of view, it first enters one detection zone (and thus one half of the pyroelectric sensor) and then the other. This causes a differential change in the amount of infrared radiation impinging on each half of the sensor. This difference in IR energy between the two halves creates an electrical signal.

- Signal Processing: The sensor's internal circuitry processes this change in voltage. If the change is significant enough (indicating a "moving heat source"), the sensor triggers an output signal.

- Security Systems: The PIR infrared sensor are a fundamental component of burglar alarms and motion-activated security cameras, detecting intruders by their body heat.

- Automatic Lighting: PIR infrared sensors are used in homes, offices, and public spaces to automatically turn lights on when someone enters a room or area and off when it's unoccupied, leading to energy savings.

- Smart Home Automation: The PIR infrared sensor play a crucial role in smart homes, triggering various automated actions like adjusting thermostats, turning on appliances, or opening doors based on occupancy.

- Automatic Doors: Many automatic door systems, like those found in shopping malls, use PIR sensors to detect approaching individuals and open the doors.

- Industrial Monitoring: They can be used to monitor machinery movement or detect the presence of personnel in hazardous areas for safety purposes.

- Wildlife Tracking and Research: Researchers use them to monitor animal movements unobtrusively.

PIR Infrared Sensor – wireless

Ship or pick up from our office.

PIR Infrared Sensor – wireless

A wireless PIR (Passive Infrared) sensor is a type of motion detector that uses infrared technology to detect the presence and movement of people, animals, or other warm objects within its field of view, and then transmits this information wirelessly to a central control unit. Here's a breakdown of its key aspects: PIR (Passive Infrared) Technology:- Passive: The "passive" in PIR means the sensor does not emit any energy (like radar or ultrasonic sensors do). Instead, it "passively" detects the infrared radiation (heat energy) naturally emitted by all objects with a temperature above absolute zero.

- Infrared Detection: All living beings (humans, pets) and warm objects emit infrared radiation.

- How it works: A PIR sensor typically has two sensing elements within its housing. When no motion is present, both elements detect the same amount of infrared radiation from the ambient environment. When a warm body moves across the sensor's field of view, it first enters one sensing element's range, causing a rapid change in the infrared energy detected by that element. As the body moves further, it then affects the second element. This differential change in infrared energy between the two elements is what the sensor interprets as motion.

- Fresnel Lens: PIR sensors often have a specialized faceted lens (a Fresnel lens) on their front. This lens helps to focus the infrared radiation onto the sensing elements and creates multiple "detection zones" or "fingers" within the sensor's field of view, which increases its coverage and sensitivity.

- No Wires for Communication: The "wireless" aspect means the sensor communicates with the alarm system's control panel (or receiver) using radio frequencies (RF) rather than physical wires.

- Battery Powered: Wireless PIR sensors are usually battery-powered, making them easy to install anywhere without needing to run electrical wiring. The batteries typically last for a significant period (months to years) before needing replacement.

- Transmitter: Each sensor has a small radio transmitter that sends a signal to the central alarm panel when motion is detected.

- Receiver: The alarm control panel has a built-in or external wireless receiver that listens for signals from the PIR sensors (and other wireless sensors like door/window contacts).

- Easy Installation: No need for complex wiring, making DIY installation simpler and reducing labor costs for professional installers. This is a significant advantage in existing structures where running wires might be difficult or aesthetically unappealing.

- Flexible Placement: Can be mounted virtually anywhere within their effective range of the control panel, providing versatile coverage.

- Reduced False Alarms (Compared to Simple Motion Detectors): Because PIR sensors detect heat signatures, they are less likely to be triggered by non-living things like swaying curtains, blowing leaves, or shadows (though extreme drafts or sudden temperature changes can still be an issue if not properly installed).

- Pet Immunity: Many wireless PIR sensors offer "pet immunity" features. These sensors are designed to ignore the infrared signatures of smaller animals (below a certain weight, e.g., 40 lbs or 80 lbs), helping to prevent false alarms in homes with pets. This is achieved by adjusting the sensor's lens and internal logic to focus on specific infrared patterns that are indicative of human-sized targets.

- Energy Efficiency: As passive devices, they consume very little power, contributing to long battery life.

- Comprehensive Coverage: Ideal for protecting large areas or rooms, as a single sensor can cover a significant space.

- Integration: Seamlessly integrate with smart home security systems, allowing for remote monitoring, alerts via smartphone apps, and sometimes even integration with other smart devices (e.g., turning on lights when motion is detected).

- Home Security Systems: Widely used indoors to detect intruders in living rooms, hallways, bedrooms, and basements. Outdoor-rated versions are also available for perimeter protection.

- Commercial Security Systems: Protecting offices, warehouses, retail spaces, and other commercial properties.

- Automated Lighting: Activating lights in rooms, hallways, or outdoor areas when someone enters.

- Smart Home Automation: Triggering various smart home routines based on occupancy (e.g., adjusting thermostat, playing music).

- Access Control: Monitoring movement in restricted areas.

- Placement: Proper placement is crucial to avoid false alarms. Avoid aiming them directly at heat sources (vents, radiators, direct sunlight, fireplaces), areas with strong drafts, or windows (especially those exposed to direct sun or busy outdoor activity).

- Pet Immunity Settings: If you have pets, ensure the sensor has pet immunity and that it's set correctly for your pet's size and the sensor's mounting height.

- Signal Range: Ensure the sensor is within the wireless range of your alarm panel, considering walls and other obstructions that might weaken the signal.

- Battery Life: Be mindful of battery replacement schedules to ensure continuous operation.

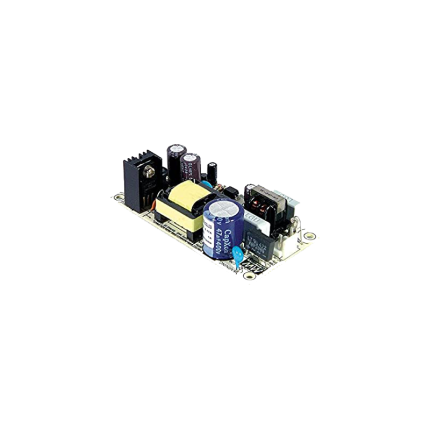

Power converter – AC 24 V to DC 12 V

Ship or pick up from our office.

Power converter - AC 24 V to DC 12 V

A power converter - AC 24 V to DC 12 V is a device that transforms alternating current (AC) at 24 volts into direct current (DC) at 12 volts. These are also commonly referred to as AC/DC power adapters or rectifiers. How it Works ⚙️ The conversion process from AC to DC typically involves several key stages:- Step-Down Transformer: The 24V AC input first goes through a transformer. This component reduces the voltage from 24V AC to a lower AC voltage, although not necessarily directly to 12V DC at this stage. It's about getting to a more manageable voltage level for the subsequent steps.

- Rectification: The reduced AC voltage then enters a rectifier circuit, usually made of diodes. Diodes allow current to flow in only one direction, effectively converting the alternating current (which periodically reverses direction) into a pulsating direct current (which flows in one direction but isn't smooth).

- Half-wave rectifiers block half of the AC waveform.

- Full-wave rectifiers (like a bridge rectifier) use both halves of the AC waveform, resulting in a smoother, more efficient conversion.

- Smoothing (Filtering): The pulsating DC output from the rectifier isn't perfectly steady. It has "ripples" or fluctuations. To smooth this out, capacitors are used. These components store electrical energy during the peaks of the waveform and release it during the dips, creating a much more stable and continuous DC voltage.

- Voltage Regulation: Finally, a voltage regulator circuit ensures that the output voltage remains consistently at the desired 12V DC, regardless of minor fluctuations in the input AC voltage or changes in the load connected to the converter. This also helps protect the connected device from voltage spikes or drops.

- CCTV cameras and surveillance systems: Many security cameras operate on 12V DC, and these converters allow them to be powered from a 24V AC power supply (which is often used in larger installations for longer cable runs due to less voltage drop).

- Low-voltage lighting: Converting 24V AC to 12V DC for certain LED lights or other low-voltage lighting systems.

- Industrial control systems: Some industrial equipment or sensors might use 12V DC power while the facility's power supply is 24V AC.

- Automotive accessories (with specific input needs): While most car systems are 12V DC, there might be niche applications where a 24V AC source needs to be converted.

- Various electronic projects and devices that require a stable 12V DC supply from an AC input.

Power converters – AC 24 V to DC 15 V

Ship or pick up from our office.

Power converters - AC 24 V to DC 15 V

A "Power converter - AC 24 V to DC 15 V" is a device that transforms an alternating current (AC) input of 24 volts into a direct current (DC) output of 15 volts. Here's a breakdown of what that means and how it works: AC (Alternating Current): This is the type of electricity typically supplied by wall outlets in homes and businesses. The voltage constantly changes direction, flowing back and forth. 24V AC is a common voltage for certain low-voltage control systems, industrial equipment, and sometimes HVAC systems. DC (Direct Current): This is the type of electricity that flows in only one direction. Most electronic devices, like phones, laptops, and many sensors or control circuits, require DC power. How an AC to DC Converter Works: An AC to DC converter (also known as a rectifier or power supply) typically involves several stages:- Step-Down Transformer: The initial 24V AC is usually too high for direct conversion to 15V DC. A transformer "steps down" this AC voltage to a lower, more manageable AC voltage.

- Rectification: This is the core of the AC to DC conversion. Diodes are used to convert the alternating current into a pulsating direct current. There are different types of rectifiers (half-wave, full-wave, bridge) that achieve this with varying degrees of efficiency and ripple.

- Smoothing (Filtering): The pulsating DC output from the rectifier isn't perfectly smooth. Capacitors are used to "smooth out" these ripples, creating a more stable DC voltage.

- Regulation: To ensure a precise and constant 15V DC output, a voltage regulator is often employed. This circuit maintains the output voltage at the desired level, even if the input voltage fluctuates or the load on the power supply changes.

- Industrial control systems: Powering sensors, actuators, and control circuits that operate on 15VDC.

- HVAC systems: Often 24VAC is used for thermostats and control panels, but some components within the system might require 15VDC.

- Security systems: Powering cameras, access control devices, and other equipment.

- Lighting systems: Especially in specialized LED lighting setups.

- Custom electronics projects: Where a stable 15VDC is needed from an existing 24VAC infrastructure.

- Output current (Amps): How much current the connected device needs.

- Power rating (Watts): The total power the converter can deliver.

- Efficiency: How much energy is lost during the conversion process (higher efficiency means less heat and less wasted energy).

- Protection features: Over-voltage, over-current, short-circuit protection for safety and device longevity.

- Form factor: Whether it's an open-frame, enclosed, or DIN-rail mount design.

Power inverter 110 V to 220 V

Ship or pick up from our office.

Power inverter 110 V to 220 V

A power inverter 110V to 220V (also known as a step-up voltage converter) is an electronic device that transforms an input voltage of 110 volts (V) into an output voltage of 220V. This type of inverter is crucial for bridging the gap between different regional electrical standards. How It Works At its core, a 110V to 220V power inverter utilizes a transformer to achieve the voltage conversion. Here's a simplified explanation:- Input (DC to AC Conversion for Inverters): While the prompt asks about a "power inverter 110V to 220V," it's important to clarify that traditional inverters convert DC (Direct Current) from a battery (e.g., 12V, 24V, 48V) into AC (Alternating Current). If the input is already 110V AC, then the device is more accurately called a voltage converter or transformer, as it's stepping up AC to AC. However, some inverters are designed to take a DC input and produce 110V AC or 220V AC, or even both.

- Step-Up Transformation: For a 110V AC to 220V AC conversion, the device contains a transformer with primary and secondary coils. The 110V AC from the power source is fed into the primary coil. Through electromagnetic induction, this voltage is "stepped up" to 220V in the secondary coil, which then becomes the output.

- Waveform: Inverters and converters can produce different types of AC waveforms:

- Pure Sine Wave: This is the most desirable waveform, replicating the smooth, consistent power from a utility grid. It's ideal for sensitive electronics.

- Modified Sine Wave: This is a cruder approximation of a sine wave and is generally suitable for less sensitive appliances, but can cause issues or damage with certain delicate electronics.

- Power Capacity (Wattage): This indicates how much power the device can supply. Ensure it's sufficient to handle the total wattage of the appliances you intend to connect. Exceeding the inverter's capacity can lead to damage.

- Efficiency: A higher efficiency rating means less energy is wasted as heat during the conversion process, which is important for battery-powered setups.

- Safety Features: Look for features like overload protection, short-circuit protection, and surge protection to safeguard your appliances and the inverter itself.

- Frequency: Electrical grids operate at either 50 Hz or 60 Hz. Ensure the inverter's output frequency matches the requirements of your appliances. Some inverters can switch between frequencies.

- Portability: Some are designed for travel, while others are larger for industrial or home use.

- International Travel: They allow travelers from countries with 110V systems (like North America) to use their 220V appliances (like hair dryers, chargers) in countries with 220V outlets (common in Europe, Asia, and other regions).

- Using Imported Appliances: If you have an appliance designed for 220V (e.g., a European kitchen appliance) but your home has 110V outlets, a step-up converter enables you to use it.

- Industrial and Specialized Applications: In industries, they can be used for automation and control systems, telecommunications, and emergency power systems to ensure compatible power supply for various equipment.

- Renewable Energy Systems: In off-grid solar or wind power setups, inverters convert DC power from batteries into the required AC voltage (which could be 110V or 220V depending on the load).

- High-Power Appliances: Some larger appliances or specialized tools might require 220V power, even in regions where 110V is standard for most household items. A converter can provide the necessary voltage without extensive electrical rewiring.

Programmable timer relay

Ship or pick up from our office.

Programmable timer relay

A programmable timer relay is an electronic device that combines the functions of a timer and a relay, allowing users to set specific time delays for switching electrical circuits on or off. Essentially, it acts as an automated switch that operates based on pre-programmed time intervals. This enables the automation of various processes and equipment across a wide range of applications. How it Works Programmable timer relays incorporate internal circuitry (often microcontrollers or digital logic chips) that allow for precise timekeeping and control. Here's a general overview of how they function:- Control Signal: The programmable timer relay receives an input or "trigger" signal, which initiates the timing process. This signal can come from a switch, sensor, or another control device.

- Timing Mechanism: Once the signal is received, the internal timing mechanism begins to count down or up based on the programmed parameters.

- Delay Period: During this delay, the relay's contacts remain in their initial state (either normally open or normally closed).

- Contact Switching: Once the programmed delay period elapses, the relay's contacts change state, either closing to allow current to flow or opening to interrupt it.

- Maintaining State & Resetting: The relay maintains its new state until the input signal is removed, or a reset function is triggered. Programmable relays offer various timing modes, such as:

- On-delay: The relay activates after a set delay once the input signal is applied.

- Off-delay: The relay deactivates after a set delay once the input signal is removed.

- Interval: The relay activates for a set period and then deactivates.

- Cyclic: The relay repeatedly alternates between on and off states for specified durations.

- Industrial Automation: They control the sequencing of machinery, conveyor belts, pumps, and other equipment in manufacturing processes, ensuring precise timing and preventing system overloads.

- Lighting Control: Used in homes, commercial buildings, and street lighting to turn lights on and off at specific times or based on ambient light levels, optimizing energy consumption and security.

- HVAC Systems: Regulate fan operations, compressor cycles, and defrost cycles in heating, ventilation, and air conditioning systems to maintain desired temperatures and reduce energy use.

- Security Systems: Implement delays for door locks, alarm systems, and surveillance cameras, allowing for controlled access and scheduled activation/deactivation.

- Pump Control: Manage water pumps, sewage pumps, and sump pumps, ensuring they operate only when needed, which conserves water and prevents pump damage.

- Home Automation: Automate various household appliances like irrigation systems, washing machines, and dishwashers.

- Vehicle Systems: Control functions like intermittent windshield wipers and turn signals.

- Versatility and Customization: They can be programmed for various timing functions and sequences within a single unit, offering great flexibility for diverse applications.

- Energy Savings: By automating on/off cycles and ensuring equipment runs only when necessary, they help reduce energy consumption and costs.

- Increased Efficiency: They enable automated control of equipment and processes, improving overall operational efficiency and reducing the need for manual intervention.

- Reduced Components and Wiring: By integrating multiple timing and switching functions into one device, they can replace several individual timers and relays, simplifying wiring, reducing component inventory, and saving space in control panels.

- Cost-Effectiveness: For simpler automation tasks, they offer a more economical solution compared to full-fledged PLCs.

- Ease of Use: Many programmable timer relays feature user-friendly digital interfaces or software, making them relatively easy to configure without requiring extensive programming knowledge.

- Precise Time Control: They offer high temporal precision, with delays ranging from milliseconds to several hours.

- Troubleshooting: Integrated displays often provide alarm messages and I/O status, simplifying troubleshooting.