Shop

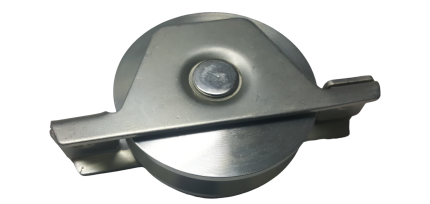

Sliding gate V-Groove wheels – SLGWSD410EB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410EB

*Steel material *Double bearing *Exterior Bracket *Max 410 Kg *98 mm Diameter x 36 mm Width *Heavy-dutySliding gate V-Groove wheels – SLGWSD410IB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410IB

*Heavy-duty *Steel material *Double bearing *Interior Bracket *Max 410 Kg *98 mm Diameter x 33 mm WidthA sliding gate V-groove wheel is a type of wheel designed to roll along a V-shaped track, providing support and guidance for sliding gates, particularly those made of metal.

The V-groove in the wheel precisely matches the track, ensuring smooth, stable, and quiet operation. These wheels are often used in industrial and heavy-duty applications due to their ability to handle significant weight and resist wear.

Here's a more detailed explanation:

-

V-Groove Design:The defining feature of these wheels is the V-shaped groove on their circumference. This groove fits snugly onto a corresponding V-shaped track, which can be made of angle iron or other suitable materials.

-

Track System:The track is typically installed along the path where the gate will slide, providing a stable and guided surface for the wheels to roll on.

-

Benefits:V-groove wheels offer several advantages, including:

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

- Stability: The V-groove design provides excellent stability, preventing the gate from wobbling or derailing.

- Durability: Many V-groove wheels are made from durable materials like steel or nylon, offering good wear resistance and longevity.

- Load Capacity: They can handle substantial weight, making them suitable for heavy gates.

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

-

Applications:V-groove wheels are commonly used in:

- Industrial Gates: Supporting heavy doors in factories and warehouses.

- Heavy-Duty Sliding Gates: For residential and commercial properties.

- Automated Gates: Used in conjunction with gate operators.

- Other Sliding Applications: They can also be found in other applications like sliding machinery or even pet gates.

- Industrial Gates: Supporting heavy doors in factories and warehouses.

-

Materials:V-groove wheels can be made from various materials, including:

- Steel: Offers high strength and load capacity.

- Nylon: Provides good wear resistance and reduced noise.

- Polyurethane: Offers a good balance of durability and quiet operation.

- Steel: Offers high strength and load capacity.

-

Installation:The wheels are typically mounted to the bottom of the gate, allowing them to roll along the track.

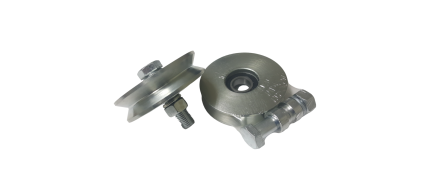

Sliding gate V-Groove wheels – SLGWSS400

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSS400

*Heavy-duty *Steel material *Single bearing *Max 400 Kg *98 mm Diameter x 32 mm Width *Heavy-duty bolts, nuts, and washers are includedSliding gate V-groove wheels are designed to roll along a V-shaped track, providing a guided and stable rolling surface for sliding gates.

These wheels are crucial for the smooth operation of sliding gates, especially those made of metal or used in industrial settings. The V-groove design minimizes friction, reduces noise and vibration, and ensures the gate remains aligned with its track.

Here's a more detailed explanation:

-

Function:V-groove wheels are specifically designed to roll along a V-shaped track, which can be made of angle iron or other suitable materials. This design provides guidance and support for the gate, preventing it from deviating from its intended path.

-

Benefits:The V-groove design offers several advantages:

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

- Noise Reduction: The smooth rolling action reduces noise and vibration compared to other wheel designs.

- Stability: The V-groove ensures the gate remains aligned with the track, preventing it from wobbling or derailing.

- Load Capacity: V-groove wheels are often designed with heavy-duty construction to handle substantial weight, making them suitable for various gate sizes and materials.

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

-

Materials:V-groove wheels are available in different materials, including:

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

- Steel: Provides strength and durability, suitable for heavy-duty applications.

- Cast Iron: Another durable option, often used for industrial applications.

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

-

Applications:V-groove wheels are used in a wide range of sliding gate applications, including:

- Residential Gates: For driveways and other entryways.

- Commercial Gates: In businesses and industrial settings.

- Industrial Doors: In factories and warehouses.

- Residential Gates: For driveways and other entryways.

Sliding gate V-Groove wheels -SLGWS800

Ship or pick up from our office.

Sliding gate V-Groove wheels -SLGWS800

Sliding gate V-Groove wheels are a fundamental component in a common type of sliding gate system. Unlike cantilever gates that hang above the ground, these gates roll directly on a track installed on the ground. Here's a detailed explanation: What they are: A V-Groove wheel is a type of wheel specifically designed with a V-shaped groove machined into its circumference. This groove perfectly mates with a corresponding V-shaped track, which is usually made of angle iron or a similar steel profile. How they work:- Track Installation: A V-shaped steel track is securely laid and typically anchored into the driveway or ground along the entire length of the gate's travel path. This track acts as the "railroad track" for the gate.

- Wheel Attachment: The V-Groove wheels are attached to the bottom frame of the sliding gate. Depending on the gate's length and weight, multiple wheels will be strategically placed along its underside.

- Guidance and Support: As the gate opens or closes (either manually or with a gate opener), the V-shaped groove of the wheels sits snugly onto the V-shaped track. This tight fit ensures:

- Smooth and Stable Movement: The gate rolls smoothly and without wobbling or derailing.

- Guidance: The wheels effectively guide the gate in a straight line, preventing it from veering off course.

- Load Distribution: The wheels bear the weight of the gate, distributing it evenly along the track.

- Materials: V-Groove wheels are typically made from durable materials to withstand heavy loads and wear:

- Steel (most common): Offers high strength, load capacity, and durability. Often zinc-plated or galvanized for corrosion resistance.

- Cast Iron: More economical but can be more prone to breakage than steel, and may require more frequent lubrication.

- Nylon or High-Impact Polymer: Quieter in operation and excellent for corrosion resistance, but generally have lower load capacities than steel and may not last as long under heavy use.

- Bearings: High-quality V-Groove wheels incorporate sealed bearings (like precision ball bearings). These reduce friction, ensure smooth rolling, and often require no lubrication, making them "maintenance-free."

- Sizes: Available in various diameters (e.g., 3", 4", 6") and load capacities (ranging from hundreds to thousands of pounds per wheel) to suit different gate sizes and weights.

- With or Without Brackets: Some wheels come with integrated mounting brackets for easier installation, while others are just the wheel itself, requiring a custom bracket or housing.

- Stability and Alignment: The V-groove design provides excellent stability, keeping the gate perfectly aligned with the track and preventing it from tilting or derailing.

- High Load Capacity: Especially steel V-Groove wheels, they are designed to handle very heavy gates, making them suitable for large residential, commercial, and industrial applications.

- Durability and Longevity: Made from robust materials, they offer a long service life, particularly with sealed bearings.

- Relatively Simple System: The concept is straightforward, and the components are widely available.

- Ground Track Maintenance: The main drawback compared to cantilever gates is that the ground track can accumulate debris (leaves, dirt, snow, ice). This debris must be regularly cleaned to ensure smooth operation and prevent damage to the wheels or opener. In Surrey, BC's climate, this is an important consideration due to rain and potential for snow.

- Driveway Disruption: Installing a ground track requires cutting into or modifying the driveway surface.

- Noise: While smoother than some other wheel types, they can still produce some noise, particularly if the track is not perfectly clean or if the wheels are worn.

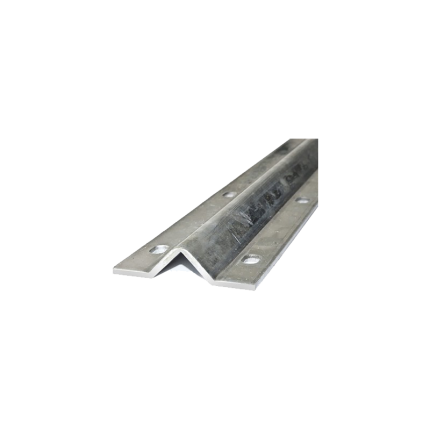

Sliding Gate V-Track

Ship or pick up from our office.

Sliding Gate V-Track

NOTE: For 25 ft sliding gate V-Track, please do not make an online order.Because of the limit of the shipping length and weight, we have to cut the full length of the product (25') to 2 x (12'-6") for pick-up from our store OR 4 x (6'-3") to send by Canada Post.

If your order requires cutting services, additional costs will apply.

To create an order for sliding gate V-Track, please send your request with the shipping address, postal code, and the length of your inquiry in the note. You will receive a quotation with the shipping costs within a maximum of one business day. A sliding gate V-track is a specific type of ground track that a sliding gate rolls on, utilizing wheels with a complementary V-shaped groove. This system is one of the most common ways to implement a sliding driveway gate, especially for residential and light commercial applications. Here's a breakdown: Purpose: The sliding gate V-track as the linear guide and support for the entire sliding gate. It ensures that the gate moves in a straight line, smoothly, and without wobbling or derailing as it opens and closes. It's an integral part of a "rolling gate" system, where the gate literally rolls on the ground. Key Characteristics and Components:- V-Shape Profile: The most defining feature. The track has an inverted V-shape or a 90-degree angle (like an angle iron) with a slightly rounded top. This V-shape mates perfectly with the V-groove wheels attached to the bottom of the gate.

- Materials:

- Galvanized Steel (Most Common): Highly durable, strong, and resistant to corrosion due to the galvanization process. It can handle heavy gates and high traffic volumes. Sections are typically joined together to form the required length.

- Aluminum: Lighter weight and excellent corrosion resistance. Often used for lighter gates or in environments where rust is a major concern (like coastal areas).

- Installation:

- Bolt-Down: The V-track is typically designed to be bolted securely to a concrete driveway or foundation. It has pre-drilled holes for anchor bolts. This allows for easier installation on existing concrete and simpler replacement if a section gets damaged.

- Embeddable (Less Common for DIY): Some V-tracks are designed to be embedded directly into wet concrete during construction.

- Level and Straight: Crucially, the V-track must be installed perfectly level and straight along the entire travel path of the gate to ensure smooth and consistent operation. Any dips, humps, or curves will cause issues with the gate's movement and can put undue strain on the gate operator and wheels.

- Lengths: Sliding gate V-tracks are sold in sections (e.g., 6 feet, 10 feet, 2.4 meters, 3 meters). Multiple sections are joined together using connection pins or by welding to achieve the total required length, which should be at least twice the width of the gate opening to allow the gate to fully retract.

- Complementary Hardware:

- V-Groove Wheels: These are essential and roll directly on top of the V-track. As discussed previously, they have a V-shaped groove that fits snugly into the track.

- Guide Rollers/Posts: Used at the top of the gate to keep it upright and prevent tipping.

- Gate Stops: Installed at the ends of the track to prevent the gate from over-traveling.

- Stability: The sliding gate V-track V-groove design provides excellent lateral stability, keeping the gate aligned and preventing it from wobbling.

- Load Capacity: Due to the direct ground support and robust V-track/wheel combination, these systems can handle very heavy and long gates.

- Simple Mechanical Principle: The system is straightforward, making it reliable.

- Debris Accumulation: The main drawback is that the V-track, being on the ground, is susceptible to collecting dirt, leaves, gravel, snow, and ice. This debris can obstruct the gate's movement, cause wear on the wheels, and may even lead to derailment or damage to the gate opener. Regular cleaning of the track is essential, especially during winter months in Canada.

- Driveway Disruption: Installing a sliding gate V-track requires modifying the driveway surface, often by bolting it down or embedding it in concrete, which creates a slight raised profile.

- Water Drainage: Proper drainage around the track is important to prevent water pooling.

Sliding gate, Full Privacy, 12 ft

Pick up from our showroom at #100, 11538 132A Street, Surrey, BC.

Sliding gate, Full Privacy, 12 ft

- Aluminum Full Privacy Sliding Gate

- Sliding Gate Package Includes: 1 x driveway gate panel, 2 x steel gate posts (8' H by 4" x 4" each), Rollers, Wheels, V-tracks

- Material: Aluminum Tube Framing, Aluminum privacy panels with a black powder paint coating

- Sliding Gate Dimensions: 12' W x 6' H.

- No hidden fees

A sliding gate is a type of gate that opens and closes by moving horizontally along a track, typically along a fence line.

Unlike swing gates, which rotate on hinges, sliding gates save space, making them ideal for narrow driveways or areas with limited space. They are commonly used in residential, commercial, and industrial settings for security and access control.

Here's a more detailed explanation:

How it works:

-

Track and Wheels:Sliding gates typically move along a track, either embedded in the ground or mounted along the fence line. They are supported by wheels or rollers that run along the track.

-

Mechanism:The gate is usually opened and closed by a motor and gear system that engages with a toothed rack on the gate, causing it to slide.

-

Space Saving:The horizontal movement allows sliding gates to operate in areas where swing gates wouldn't be feasible due to space constraints.

-

Security:Sliding gates offer a robust security solution, especially when combined with access control systems.

-

Types:Common types include traditional sliding gates, which use a track, and cantilever gates, which don't require a ground track and are supported by a counterbalance system.

-

Benefits:They are known for their space-saving design, ease of installation (especially cantilever gates), and minimal maintenance.

Smart Video Doorbell

Ship or pick up from our office.

Smart Video Doorbell

*WiFi connection *Android/IOS app on the smartphone *Answer visitors using smartphone worldwideStand-Alone Fingerprint Access Control

Support Roller

Ship or pick up from our office.

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.

Swing gate – Deer design – 14 ft

Swing gate - Deer design - 14 ft

- Pick up from our showroom at #100, 11538 132A Street, Surrey, BC.

- Royal Gate Deer Style Dual Swing Driveway Gate

- Gate Package Includes: 2 x driveway gate panel, 2 x steel gate posts (8′ H by 4″ x 4″ each), 4 x Heavy duty adjustable steel hinges

- Material: Hot Dip Galvanized steel gate with a black powder paint coating

- Gate Dimensions: 14′ W x 6′ H.

- No hidden fees