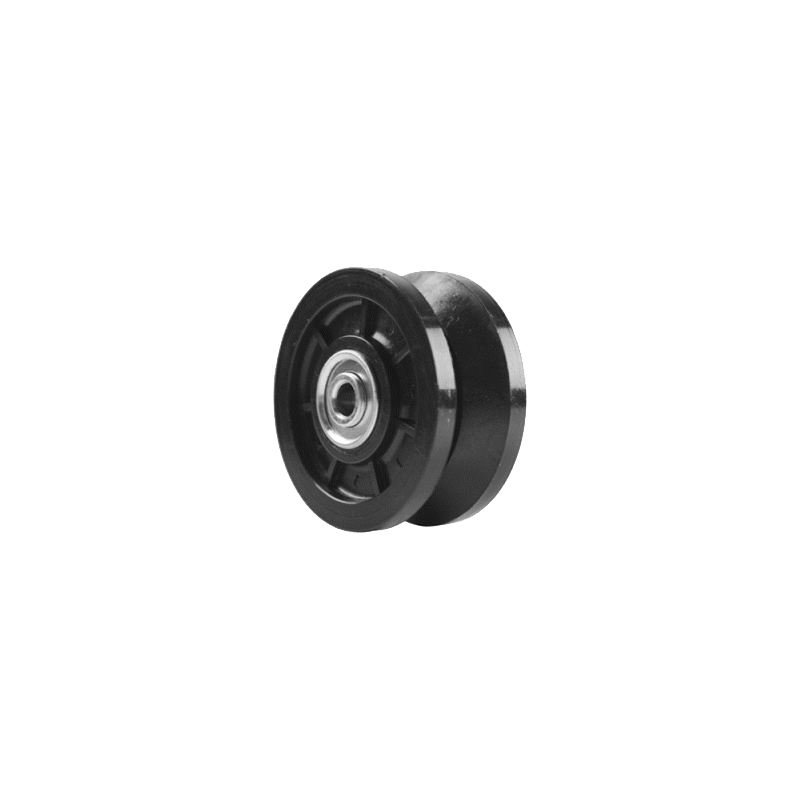

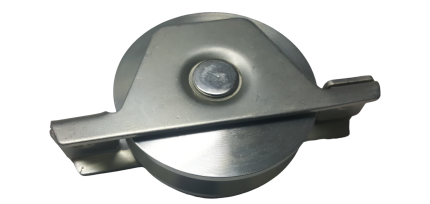

Sliding gate V-Groove nylon wheels -SLGWN778MLB

The wheels, typically made of nylon, feature a V-shaped groove that precisely matches the track, ensuring stability and reducing friction. This design helps to minimize noise, vibration, and wear, making them suitable for various applications, including heavy-duty sliding doors, industrial machinery, and even pet gates.

-

V-Groove Design:

The V-shaped groove in the wheel aligns perfectly with a corresponding V-shaped track, providing a stable and guided rolling surface.

-

Nylon Material:

Nylon offers several advantages, including good wear resistance, low friction, and the ability to withstand various environmental conditions.

-

Double Bearings:

Many V-Groove wheels incorporate double bearings for enhanced stability, smooth rolling, and increased load capacity.

-

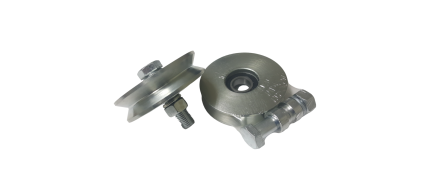

Heavy-Duty Construction:

The wheels are often made with a robust steel bracket that can handle substantial weight and provide a stable platform for the gate.

-

Corrosion Resistance:

The wheel’s bracket may be galvanized or coated to protect it from rust and corrosion.

-

Versatile Applications:

These wheels are suitable for a wide range of sliding gate applications, including residential, commercial, and industrial settings.

-

Smooth and Quiet Operation:

The V-groove design and nylon material help reduce friction and noise during gate movement.

-

Durability and Longevity:

The robust construction and wear-resistant nylon material ensure a long service life.

-

Reduced Maintenance:

The wheels require minimal maintenance due to their durable construction and smooth rolling action.

-

Stable and Secure Movement:

The V-groove and bearing system provides a stable and secure rolling surface for the gate.

-

Load Capacity:

V-Groove wheels are available in various sizes and load capacities to accommodate different gate sizes and weights.

-

Track Compatibility:

Ensure that the V-groove wheel’s specifications match the track’s dimensions for optimal performance.

-

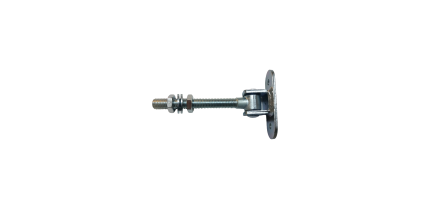

Installation:Proper installation is crucial for the longevity and performance of the wheels. Ensure the track is properly aligned and the wheels are securely mounted.

Reviews

There are no reviews yet.