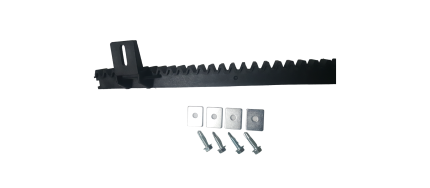

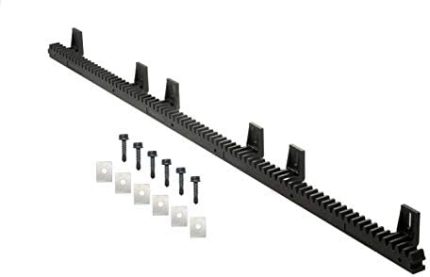

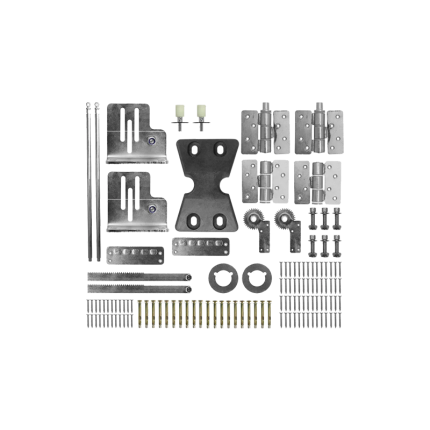

Sliding gate operator gear rack -SLGR612

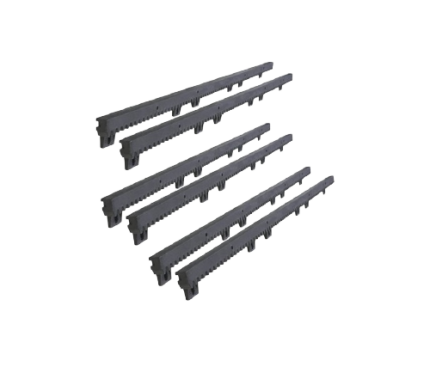

The nylon material offers a lightweight and durable option for the rack, while the steel core provides added strength and stability.

-

Function:

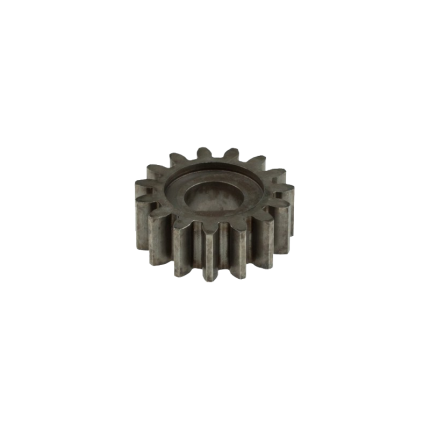

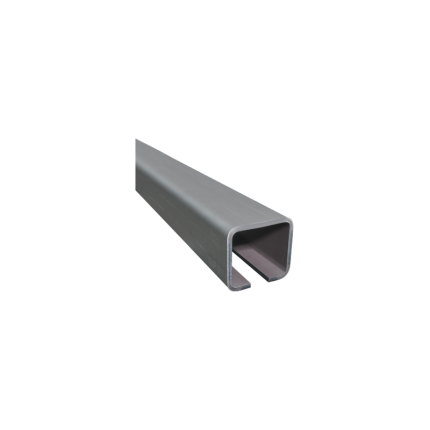

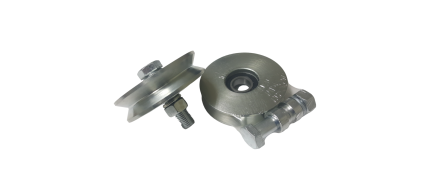

The sliding gate operator gear rack -SLGR612 is attached to the sliding gate, and the pinion gear (connected to the motor) engages with the rack’s teeth. As the pinion rotates, it moves the rack and thus the gate along its track.

-

Materials:

While some racks may be made entirely of metal, nylon is a popular choice due to its lightweight nature and ability to withstand wear and tear. The steel core provides the necessary strength and stability to handle the gate’s weight and movement.

-

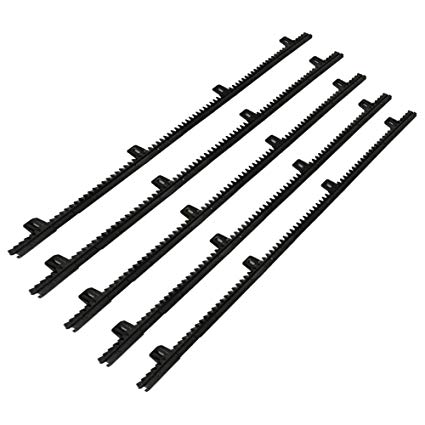

Types:

Nylon gear racks are available in various configurations, including standard, double-toothed, crowned, and spiral, each with its advantages for specific gate systems.

-

Installation:

The rack is typically mounted to the bottom of the gate, with the teeth facing downward. It’s crucial to ensure proper alignment with the pinion gear for smooth and reliable operation.

-

Advantages:Using a sliding gate operator gear rack -SLGR612 with a steel core offers a balance of durability, quiet operation, and corrosion resistance, making it suitable for various sliding gate applications.

Reviews

There are no reviews yet.