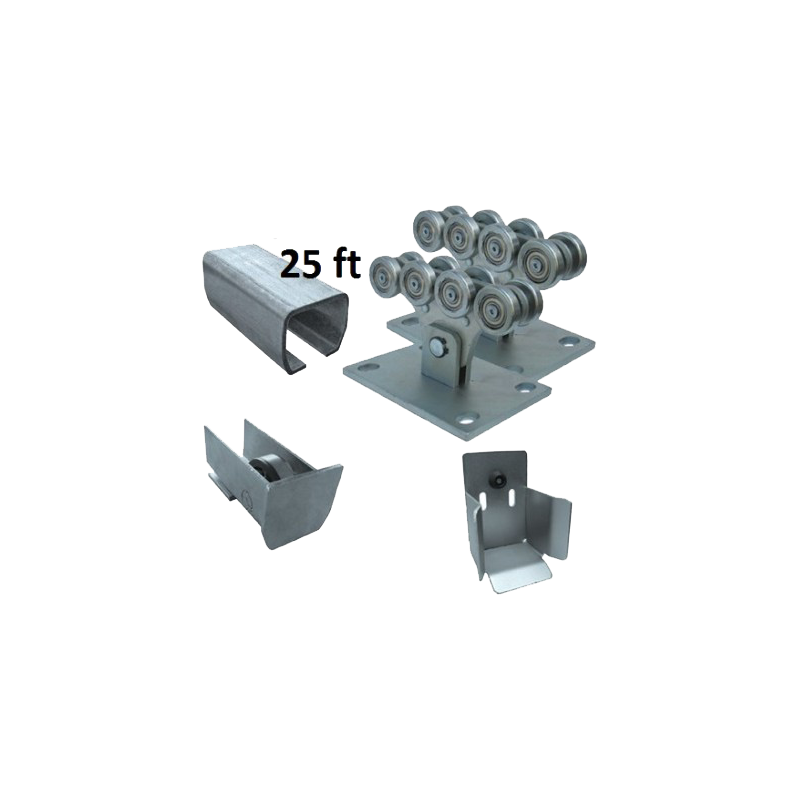

Cantilever Sliding Gate Hardware

Cantilever mechanism sliding driveway gate kit is the highest version of the sliding gates.

The cantilever mechanism is suitable for gates with a maximum of 500 Kg

We can not ship the cantilever tracks because of Canada Post’s limited length, so if you need to have this package, you have to submit your order and choose the local pickup option.

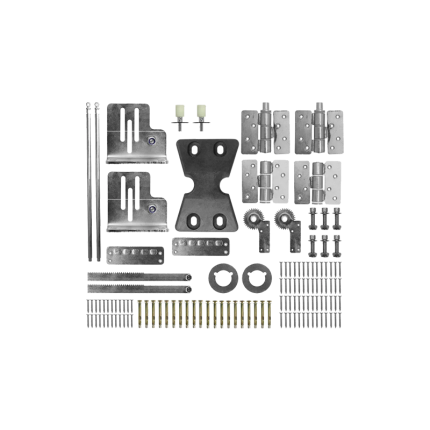

Included:

*2 x Trolley carriage 8 Wheels

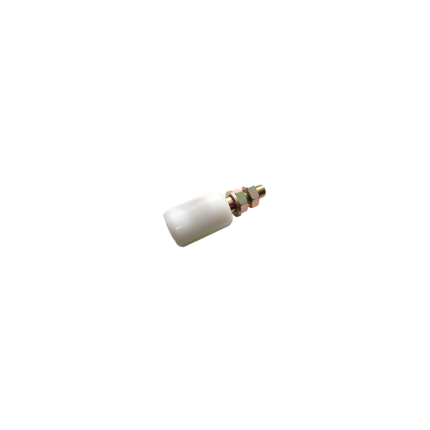

*1 x Stopper

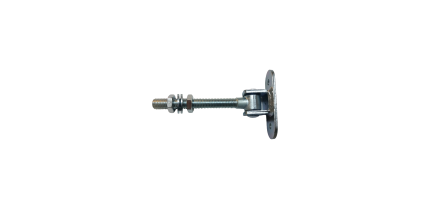

*1 x Roller stop wheel

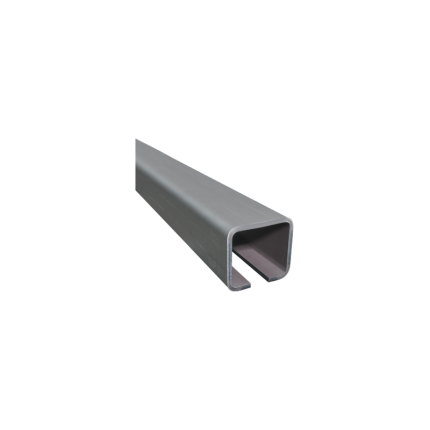

*25′ Aluminum track (3” H x 2” W)

A cantilever gate is a type of sliding gate that does not require a ground track.

Instead, it is supported by rollers attached to posts on one side of the opening, allowing the gate to slide open and closed without touching the ground.

This design makes them suitable for uneven surfaces and areas where ground tracks are not feasible.

A cantilever mechanism in sliding driveway gates refers to a design where the gate is supported and guided by rollers mounted on a vertical post, allowing it to slide open and closed without requiring a track on the ground. This differs from traditional sliding gates that rely on a track for support.

The cantilever design is particularly useful for driveways with uneven surfaces, debris, or snow, as it eliminates the need for a ground track.

-

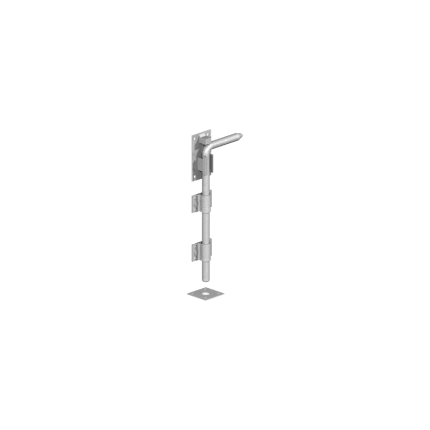

No Ground Track:

Unlike traditional sliding gates, cantilever gates do not have a track on the ground for the gate to roll on.

-

Support System:

Cantilever gates are supported by a system of rollers attached to a vertical post, usually located on one side of the gate opening.

-

Suspended Operation:

The gate is suspended above the ground and slides open and closed by rolling along the rollers mounted on the support post.

-

Counterbalance:

Cantilever gates are typically counterbalanced to ensure smooth and stable operation, especially when opening and closing.

-

Benefits:

This design is ideal for driveways with uneven surfaces, debris, or snow, as it avoids the issues associated with ground-level tracks.

-

Installation:Cantilever gates may require more precise installation of the support posts and rollers, but they offer advantages in terms of reduced maintenance and better operation in challenging environments.

Reviews

There are no reviews yet.