Sliding gate

Gate Opener Remote Control 1400FT315/2-CH

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315/2-CH

A high-range gate opener remote control 1400FT315/2-CH allows you to operate your gates from a greater distance than standard remotes, typically offering a range of several hundred feet or even up to a mile or more.

These remotes are often used in situations where the gate is located far from the entrance or when there are obstructions between the remote and the receiver.

Here's a more detailed explanation about Gate Opener Remote Control 1400FT315/2-CH:

What makes it high-range?

-

Stronger Transmitter:High-range remotes have a more powerful transmitter than standard remotes, allowing them to send a stronger signal over a longer distance.

-

Specialized Receiver:These remotes often work with a specialized receiver that is more sensitive and capable of picking up weaker signals.

-

Frequency:High-range remotes typically operate on a specific frequency (e.g., 433MHz or 315MHz) that is less prone to interference and allows for better transmission.

Benefits of high-range remotes like as the Gate Opener Remote Control 1400FT315/2-CH:

-

Increased Convenience:You can open your gate from a greater distance, which is particularly useful for large properties or when driving up to the gate.

-

Improved Security:High-range remotes can help prevent unauthorized access by allowing you to activate the gate from a safe distance.

-

Enhanced Flexibility:They can be used in a wider range of situations, such as when you need to open the gate for deliveries or visitors.

Factors affecting range:

-

Line of Sight:The range is usually maximized when there is a clear line of sight between the remote and the receiver.

-

Obstructions:Walls, trees, and other obstructions can reduce the range of the remote.

-

Weather Conditions:Extreme weather conditions like heavy rain or snow can also affect the range.

-

Antenna Placement:Proper placement of the antenna on the receiver can help improve the range.

Gate Opener Remote Control 1400FT315

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315

*High-Range 1400ft *315 MHz *Compatible with HomeLink system on vehicles *1 channelSliding Gate Opener -Zero ZSL1000

Ship or pick up from our office.

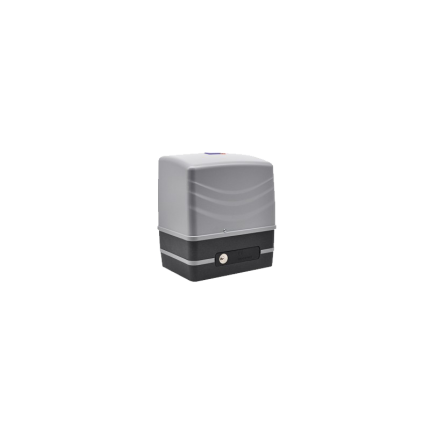

Sliding Gate Opener -Zero ZSL1000

*Suitable gate weight: Maximum 1000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release keySliding gate opener – VDS Carrera SL800

Ship or pick up from our office.

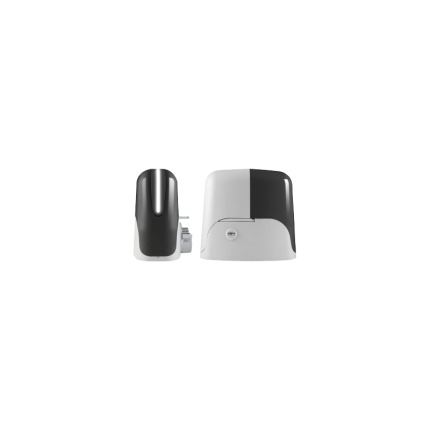

Sliding gate opener - VDS Carrera SL800

Suitable gate weight: Maximum 800 Kg Included:- 1 x Electromechanical motor

- 1 x Main control board

- 4 Meters x SLGR41 Gear rack

- 2 x Remote control

- 2 x Manual release key

- 1 x Base Plate

- 2 x Limit Switch bracket

- Installation Manual

- Programming Manual

Key Features of the VDS Carrera Gate Openers:

-

Sliding Gate Compatibility:The Carrera series is designed for sliding gates, utilizing a gear rack-driven mechanism.

-

Weight Capacity:Models are available for gates weighing up to 800 kg (Carrera 800) and 1000 kg (Carrera 1000).

-

Robust Construction:The motors feature steel and cast iron gears, lubricated with lithium grease for corrosion resistance and quiet operation, according to VDS Automation.

-

Control and Safety:They include a control unit with an air-stop seal, anti-squashing system, and options for electronic torque control and slowing down.

-

Easy Programming:The pre-wired systems are designed for easy programming and installation.

-

Optional Accessories:Keypads, remote control radio receivers, and safety sensors can be integrated.

-

Made in Italy:VDS Automazioni is an Italian company that emphasizes the quality and safety of its products.

-

Manual Release:A manual release lever with a custom key is included for emergency situations.

Sliding gate opener -VDS Carrera SL1000

Ship or pick up from our office.

Product Sheet PDF

Sliding gate opener -VDS Carrera SL1000

*Suitable gate weight: Maximum 1000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release key *1 x Base Plate *2 x Limit Switch bracket *Installation Manual *Programming ManualSliding gate opener -Key Automation TURBO82120

Ship or pick up from our office.

Product Sheet PDFSliding gate opener -Key Automation TURBO82120

Included in the Package:

- 1 x Electromechanical motor

- 1 x Main control board

- 4 Meters x SLGR41 Gear rack

- 2 x Remote control

- 2 x Manual release key

TECHNICAL FEATURES

| Speed | cm/s | 16 |

| Torque | Nm | 23 |

| Duty cycle percentage | % | 30 |

| Control unit | CT102B | |

| Voltage | Vac | 120 |

| AC Voltage Frequency | Hz | 50/60 |

| Nominal current | A | 1,9 |

| Nominal power | W | 450 |

| Appliance isolation class | I | |

| Degree of protection | IP | 44 |

| Dimensions (L - D - H) | mm | 320 - 184 - 260 |

| Item | kg | 13 |

| Minimum operating temperature | °C | -20 |

| Max operating temperature | °C | +55 |

| Max leaf weight | kg | 800 |

Sliding gate opener -Key Automation SUN7224

Ship or pick up from our office.

Product Sheet PDFSliding gate opener -Key Automation SUN7224

Electromechanical gear motor for sliding gates up to 700 kg:

- With a slowdown function both in opening and closing to preserve gate integrity

- Electronic and mechanical parts are well protected from external agents

- Easy maintenance thanks to the horizontal control unit position

- High technological materials resistant to weather conditions

- Gear reduction with an extra-large bearing with high performance

- Extremely silent mechanics, protected by a robust die-cast and powder-coated aluminum body

- With 24 Vdc control unit CT10224

- The release system is ergonomic, efficient, and easily accessible

- Opens gates weighing up to 700 kg

- Easy to install and programming

- Get the desired torque and tension by adjusting the parameters

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate opener –Key Automation SUN11024

Ship or pick up from our office.

Product Sheet PDFSliding gate opener –Key Automation SUN11024

High-quality Italian-made with state-of-the-art technology and design. Open gates weighing up to 1100 KG effortlessly with this gear rack-driven sliding gate opener. It is designed with a 24V DC motor, which provides exceptional torque, and its continuous operation makes it ideal for most applications. A 13 ft nylon gear rack track is included in the kit, and if your gates are more than 13 ft in length, then you can opt for an extra rack.- Opens gates weighing up to 1100 kg

- Easy to install and program

- Get the desired torque and tension by adjusting the parameters using the KUBE PRO and PROGRAMMING MODULE

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate operator limit sensor – Magnetic mechanism

Ship or pick up from our office.

Sliding gate operator limit sensor - Magnetic mechanism

A sliding gate operator limit sensor, often a limit switch, is a crucial component that signals the gate operator when the gate has reached its fully open or fully closed position, stopping the motor and preventing over-travel. These sensors ensure the gate stops at the correct positions, preventing damage to the gate and surrounding structure.

Here's a more detailed explanation:

-

Function:Limit sensors, like limit switches, detect when the gate reaches its extreme open or closed positions.

-

How it works:When the gate reaches the limit, the sensor sends a signal to the gate operator's control board, which then stops the motor.

-

Importance:Without limit sensors, the gate might continue to move, potentially hitting the end posts or other obstructions, causing damage.

-

Types:Common types include magnetic limit switches and photoelectric sensors (photo eyes).

-

Magnetic Limit Switches:These utilize magnets placed on the gate and a magnetic sensor on the operator. When the magnet aligns with the sensor, it triggers the limit switch.

-

Photoelectric Sensors (Photo Eyes):These use infrared beams to detect obstructions. When the beam is broken (e.g., by the gate), the sensor signals the operator to stop.

-

Installation:Proper installation and adjustment of limit sensors are crucial for the reliable operation.

-

Maintenance:Regular inspection and maintenance of limit sensors are recommended, as they can wear out or become misaligned over time.

Sliding gate operator main control board – Zero

Ship or pick up from our office.

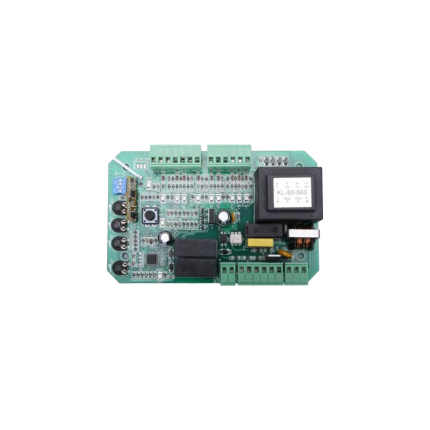

Sliding gate operator main control board – Zero

The sliding gate operator main control board (also referred to as a PCB or circuit board) is the central component that manages all the functions of an automatic sliding gate system.

It acts as the "brain" of the gate, receiving signals from various input devices (like remote controls, keypads, or safety sensors) and translating them into actions for the gate's motor and other components.

Here's a more detailed breakdown:

1. Central Control: The control board is the central hub for all gate operations. It receives signals from different sources, such as:

- Remote controls: For opening and closing the gate.

- Keypads: For authorized access.

- Safety sensors: To detect obstructions and prevent accidents.

- Other accessories: Such as loop detectors, intercom systems, etc.

2. Signal Processing: The control board interprets the signals it receives and determines the appropriate action for the gate.

3. Motor Activation: Based on the processed signal, the control board sends instructions to the gate's motor to either open or close the gate.

4. Adjustable Settings: The control board often allows for adjustments to various parameters, including:

- Gate speed: The speed at which the gate opens and closes.

- Opening and closing timers: To control the duration of the gate's movement.

- Safety features: Including force adjustments, obstacle detection sensitivity, and slow-down settings.

Sliding gate operator main control board – VDS

Ship or pick up from our office.

Sliding gate operator main control board – VDS

The VDS SIMPLY sliding gate operator's main control board is the central unit that controls the operation of a sliding gate, typically one that weighs up to 600kg.

It's made by VDS Automation, an Italian company known for its gate automation products.

This control board manages functions like opening and closing the gate, potentially adjusting speed and force, and integrating with accessories such as keypads and safety sensors.

-

Central Control:The control board acts as the brain of the gate, receiving signals from remote controls or other input devices and translating them into actions for the gate's motor and other components.

-

Remote Control Integration:It typically includes a built-in radio receiver that can be programmed to work with VDS remote controls.

-

Safety Features:The control board can manage safety mechanisms like anti-squashing systems and potentially adjustable speed and force settings.

-

Easy Installation and Programming:The VDS SIMPLY control board is designed for easy installation, often featuring pre-wired components and straightforward programming.

-

Optional Accessories:It can be integrated with optional accessories like keypads, safety sensors, and other components to enhance functionality.

-

Durability:The control unit is often housed in a box with an air-stop seal to protect it from moisture and insects, and the mechanical parts may be lubricated with lithium grease for longevity.

-

Italian Manufacturing:VDS (Simply SL110) is specifically mentioned as an Italian-made control board, emphasizing quality and reliability.

Cantilever sliding gate track

Ship or pick up from our office.

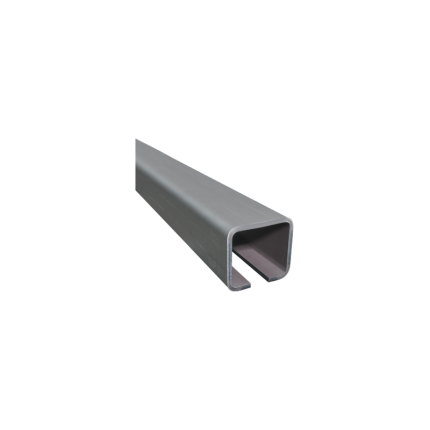

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.