Ship or pick up from our office.

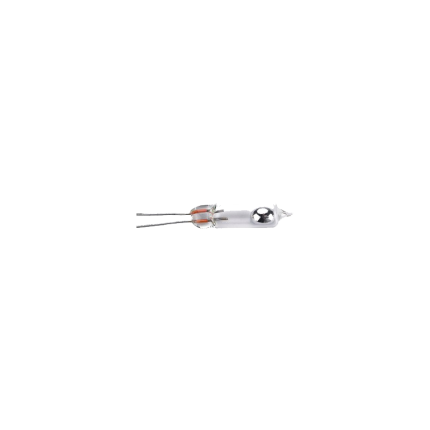

Mercury Level Switch

A mercury level switch is a type of electrical switch that uses a small amount of liquid mercury to open or close an electrical circuit based on its position or the level of a liquid. Essentially, the mercury acts as a conductive bridge between electrical contacts.

How it Works

The core component of a mercury level switch is a

sealed glass or metal capsule containing one or more electrical contacts and a small, free-moving drop of mercury.

When the switch or the liquid it's monitoring changes its tilt or level:

- Tilt Switches: Gravity pulls the mercury to the lowest point within the capsule. If the tilt is sufficient, the mercury will flow to connect two or more contacts, completing an electrical circuit. Tilting it in the opposite direction moves the mercury away, breaking the circuit.

- Float Switches: In liquid level applications, the mercury switch is often integrated with a float mechanism. As the liquid level rises or falls, the float moves, which in turn tilts the mercury switch, causing the mercury to connect or disconnect the contacts.

- Displacement Switches: Some designs use a "plunger" that dips into a pool of mercury, raising the mercury level to contact an electrode and complete the circuit.

Applications

Historically, mercury level switches were used in a wide range of applications due to their reliability and the non-eroding nature of mercury contacts. These included:

- Thermostats: In older thermostats, they controlled heating and cooling systems.

- Sump Pumps: Used to automatically turn on the pump when water levels rise.

- Appliances: Found in washing machines (for lid switches and load balancing), chest freezers (for lid lights), and some gas appliances like ovens and water heaters (as flame sensors).

- Automotive Industry: Previously used for trunk lid lights, ride control, and anti-lock braking systems.

- Industrial Settings: Utilized in liquid level control and safety systems.

- Roll Sensing/Tip-over Warnings: For construction equipment or other vehicles operating on uneven terrain.

Advantages and Disadvantages

Advantages:

- Durability and Reliability: The sealed contacts prevent oxidation, leading to a long lifespan.

- Quiet Operation: No abrupt snapping of contacts.

- No Contact Erosion: Mercury's liquid nature prevents the wear and tear seen in mechanical contacts.

- Spark-Free: They don't produce sparks when making or breaking circuits, making them suitable for hazardous environments.

Disadvantages:

- Toxicity of Mercury: This is the primary and most significant disadvantage. Mercury is a highly toxic substance, posing serious environmental and health risks if released.

- Environmental Concerns: Improper disposal of mercury switches can lead to widespread contamination. Due to these concerns, the use of mercury switches has been largely phased out in many applications, especially in new products.

- Sensitivity to Gravity/Orientation: While an advantage for tilt sensing, it makes them unsuitable for portable or mobile devices where orientation changes or vibrations could cause false readings.

- Limited Functionality: Most mercury switches provide only a simple on/off function.

Due to the toxicity of mercury, many applications that once relied on mercury switches have transitioned to safer, alternative technologies such as solid-state sensors, optical sensors, or mechanical float switches.