gate motor

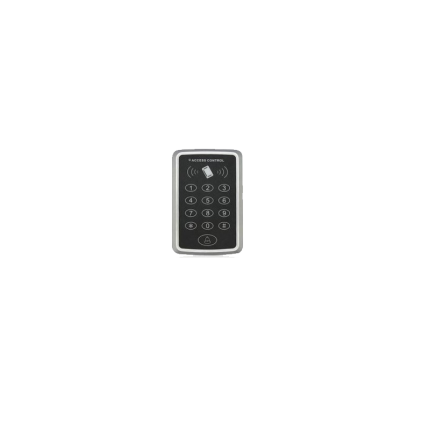

Keypad KO05SC107

Ship or pick up from our office.

Keypad KO05SC107

*Waterproof Keypad Version *EM/ID card/tag reader *Backlight Keypad *1000 Users *DC 12 V *Rain Shield Cover included in the keypad package The Keypad KO05SC107 is a standalone RFID access control keypad that is used to restrict entry to authorized individuals by requiring them to enter a specific code or PIN, or use an RFID card. 🔑 It's manufactured by Royal Electronics Technology Center Co. and is suitable for indoor use, although a rain shield cover is often included. Key Features & Specifications The KO05SC107 offers a range of features designed for security and convenience:- Access Methods: Users can gain entry by entering a PIN, using an RFID card, or a combination of both (card + PIN).

- User Capacity: It can store up to 1000 users, making it suitable for various settings like residential buildings, commercial properties, and industrial facilities.

- Card Reader Mode: It functions as an RFID card reader, and the transmission format can be adjusted by the user.

- Customization: Access can be customized for specific times or individuals, providing enhanced control.

- Integration: It can be integrated with other security systems such as intercoms, video surveillance, and alarm systems.

- Dimensions: The keypad has dimensions of 16 × 11 × 11 cm and weighs 0.4 kg.

- Durability: Some versions are waterproof.

- Residential homes

- Commercial offices

- Industrial facilities

- Any entry point where controlled access is needed, such as gates or doors.

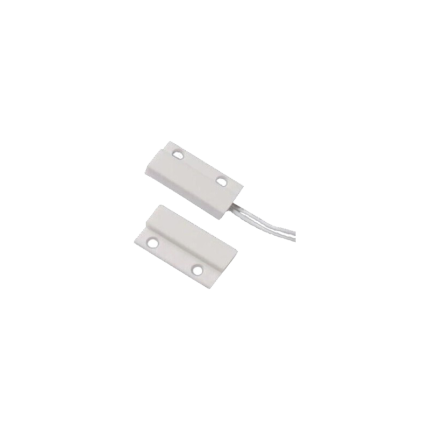

Magnetic Contact Switch – Wired

Ship or pick up from our office.

Magnetic Contact Switch

A magnetic contact switch, often simply called a magnetic contact or door/window sensor, is a simple yet highly effective security device that detects when a door, window, gate, or any movable barrier is opened or closed. How it Works: It consists of two main parts:- The Sensor Unit (with a Reed Switch): This part contains a reed switch. A reed switch is a small, hermetically sealed (airtight) glass capsule with two tiny, flexible magnetic metal reeds (or contacts) inside. These reeds are usually made of a ferromagnetic material. This sensor unit is typically mounted on the stationary part of the opening (e.g., the door frame, window frame, or gate post).

- The Magnet Unit: This part contains a small, permanent magnet. This unit is mounted on the moving part of the opening (e.g., the door itself, the window sash, or the gate panel).

- Closed Position (Circuit Complete): When the door/window/gate is closed, the magnet unit is in very close proximity to the sensor unit. The magnetic field from the permanent magnet pulls the two tiny reeds inside the glass capsule together, causing them to make electrical contact. This completes an electrical circuit, indicating that the opening is secured.

- Many common contacts are "Normally Open" (NO), meaning the circuit is open when the magnet is away and closes when the magnet is near.

- Some are "Normally Closed" (NC), meaning the circuit is closed when the magnet is near and opens when the magnet is away. This is very common in security systems, as an "open" circuit triggers an alarm.

- Opened Position (Circuit Broken/Changed): When the door/window/gate is opened, the magnet moves away from the reed switch. As the magnetic field weakens, the reeds spring back to their original position, breaking the electrical contact. This change in the circuit (from closed to open, or open to closed, depending on the type) signals the connected system (e.g., a car alarm, home security system, or gate control panel) that the opening has occurred.

- Security Systems (Homes, Businesses, Vehicles): This is the most prevalent use. Magnetic contacts are placed on:

- Doors and Windows: To detect unauthorized entry. When a door or window is opened, it triggers the alarm.

- Garage Doors/Overhead Doors: Larger, more robust magnetic contacts are used for garage doors.

- Gates: Used on pedestrian gates or even main driveway gates (sometimes in conjunction with the gate opener's own limit switches) to monitor their open/closed status for security purposes.

- Safes and Vaults: To detect if they have been opened.

- Vehicle Doors/Trunks/Hoods: While vehicles have internal sensors, magnetic contacts can be added for enhanced security on specific compartments or custom modifications.

- Access Control Systems: To monitor entry and exit points, log access events, or control other devices based on door status.

- Automation Systems: To trigger actions based on the status of a movable part. Examples include:

- Turning lights on/off when a door opens.

- Indicating when a cabinet door is ajar.

- Position sensing in industrial machinery.

- Appliance Safety: Some appliances use magnetic contacts to ensure a lid is closed or a guard is in place before operation.

- Surface Mount: Most common, easily screwed or adhered to the surface of the frame and door.

- Recessed/Flush Mount: Designed to be drilled into the frame and door for a more discreet, hidden installation.

- Heavy Duty/Overhead Door Contacts: Larger and more rugged, built for the heavier use and larger gaps often found with garage or industrial doors.

- Wired vs. Wireless:

- Wired: Physically connected to the alarm panel via wires, offering high reliability.

- Wireless: Contain a small battery and a radio transmitter to send signals wirelessly to the alarm panel, offering easier installation.

Magnetic lock

Ship or pick up from our office.

Magnetic lock

*Capacity: 180 Kg *DC 12 V A magnetic lock, also known as an electromagnetic lock or maglock, is a locking device that uses the principles of electromagnetism to secure a door. Unlike traditional mechanical locks, it has no moving parts. How It Works A magnetic lock consists of two main components:- Electromagnet: This is typically mounted on the door frame. It contains a coil of wire wrapped around a ferromagnetic core.

- Armature Plate: This is a steel plate mounted on the door itself, designed to align with the electromagnet.

- High Security: Magnetic locks can provide a very strong holding force, making them difficult to force open. They are also virtually unpickable, as there are no keyholes or cylinders.

- Durability and Low Maintenance: With no moving parts, magnetic locks experience less wear and tear than traditional locks, leading to greater longevity and reduced maintenance needs.

- Quick Operation: They unlock instantly when power is cut, allowing for quick release, which is beneficial in high-traffic areas or emergencies.

- Remote Operation and Access Control Integration: Magnetic locks can be easily integrated into electronic access control systems, allowing for remote operation, key card/fob access, biometric scanning, and detailed access logging.

- Versatility: They can be installed on various door types, including glass, wood, and metal, and are suitable for both swinging and sliding doors.

- Ease of Installation: Compared to some other electric locks, maglocks can be relatively straightforward to install.

- Constant Power Requirement: Magnetic locks need a continuous power supply to remain locked. This means they are dependent on electricity, and a power outage will result in the door unlocking (fail-safe).

- Cost: While the initial cost of the lock itself might be comparable, the overall installation can be more expensive due to the need for electrical wiring, power supplies, and integration with other security systems.

- Additional Hardware for Safety: To comply with building codes and ensure safe egress, magnetic locks often require additional hardware such as push-to-exit buttons, motion sensors, or panic bars.

- Maintenance of Backup Systems: If battery backups are used to mitigate power outages, these batteries require regular checking and replacement.

Manual release key – Swing/Sliding gate openers

Ship or pick up from our office.

Manual release key – Swing/Sliding gate openers

A swing or sliding gate opener release key is a tool that allows you to manually operate a swing gate when the automatic opener is not functioning, such as during a power outage. It disengages the automatic mechanism, enabling the gate to be opened or closed manually.

Here's a more detailed explanation:

-

Purpose:The key is used to unlock the gate opener's motor, allowing it to be moved by hand.

-

Location:The release mechanism is often found near the gate motor, either on the motor itself or in a nearby housing.

-

Functionality:The key may turn a dial or lever that releases the motor's gears, enabling manual operation.

-

Importance:This manual release mechanism is essential for emergency access and situations where the automatic system is unavailable.

Mercury Level Switch

Ship or pick up from our office.

Mercury Level Switch

A mercury level switch is a type of electrical switch that uses a small amount of liquid mercury to open or close an electrical circuit based on its position or the level of a liquid. Essentially, the mercury acts as a conductive bridge between electrical contacts. How it Works The core component of a mercury level switch is a sealed glass or metal capsule containing one or more electrical contacts and a small, free-moving drop of mercury. When the switch or the liquid it's monitoring changes its tilt or level:- Tilt Switches: Gravity pulls the mercury to the lowest point within the capsule. If the tilt is sufficient, the mercury will flow to connect two or more contacts, completing an electrical circuit. Tilting it in the opposite direction moves the mercury away, breaking the circuit.

- Float Switches: In liquid level applications, the mercury switch is often integrated with a float mechanism. As the liquid level rises or falls, the float moves, which in turn tilts the mercury switch, causing the mercury to connect or disconnect the contacts.

- Displacement Switches: Some designs use a "plunger" that dips into a pool of mercury, raising the mercury level to contact an electrode and complete the circuit.

- Thermostats: In older thermostats, they controlled heating and cooling systems.

- Sump Pumps: Used to automatically turn on the pump when water levels rise.

- Appliances: Found in washing machines (for lid switches and load balancing), chest freezers (for lid lights), and some gas appliances like ovens and water heaters (as flame sensors).

- Automotive Industry: Previously used for trunk lid lights, ride control, and anti-lock braking systems.

- Industrial Settings: Utilized in liquid level control and safety systems.

- Roll Sensing/Tip-over Warnings: For construction equipment or other vehicles operating on uneven terrain.

- Durability and Reliability: The sealed contacts prevent oxidation, leading to a long lifespan.

- Quiet Operation: No abrupt snapping of contacts.

- No Contact Erosion: Mercury's liquid nature prevents the wear and tear seen in mechanical contacts.

- Spark-Free: They don't produce sparks when making or breaking circuits, making them suitable for hazardous environments.

- Toxicity of Mercury: This is the primary and most significant disadvantage. Mercury is a highly toxic substance, posing serious environmental and health risks if released.

- Environmental Concerns: Improper disposal of mercury switches can lead to widespread contamination. Due to these concerns, the use of mercury switches has been largely phased out in many applications, especially in new products.

- Sensitivity to Gravity/Orientation: While an advantage for tilt sensing, it makes them unsuitable for portable or mobile devices where orientation changes or vibrations could cause false readings.

- Limited Functionality: Most mercury switches provide only a simple on/off function.

Micro Limit Switch

Ship or pick up from our office.

Micro Limit Switch

A micro limit switch, often simply called a micro switch, is a type of electrical switch that's characterized by its small size and the precise, rapid action it takes when a minimal amount of force is applied to its actuator. It's designed to detect the presence or position of an object or the end of a mechanical movement. These switches are known for their:- High sensitivity: They require very little force to activate.

- Rapid response: The internal contacts "snap" open or closed very quickly, regardless of how slowly the actuator is pressed. This snap-action mechanism helps to reduce arcing and extends the switch's lifespan.

- Reliability: They are built to withstand millions of operations, making them durable for long-term use.

- Compact size: Their small footprint allows them to be used in applications where space is limited.

- Actuator: This is the external part that an object or mechanical component presses against. It can be a button, a lever (with or without a roller), a plunger, or other forms.

- Internal spring mechanism: This provides the "snap-action." When the actuator is pressed to a certain point (the "trip point"), the spring mechanism rapidly moves the contacts.

- Contacts: These are the electrical components that open or close the circuit. Micro switches usually have three terminals:

- Common (C): The input terminal.

- Normally Open (NO): This contact is open (no current flows) when the switch is unactivated and closes when the switch is actuated.

- Normally Closed (NC): This contact is closed (current flows) when the switch is unactivated and opens when the switch is actuated

- Household Appliances:

- Microwave ovens: To detect if the door is closed before operating.

- Washing machines: For door interlocks and water level detection.

- Refrigerators: To turn the light on/off when the door opens/closes.

- Printers: To detect paper jams or the position of paper.

- Automotive Industry:

- Car doors: To detect if a door is open or closed (e.g., for interior lights or security systems).

- Brake pedals: To activate brake lights.

- Seat belt mechanisms: To detect if a seat belt is fastened.

- Industrial Automation:

- Conveyor systems: To detect the presence of items or the end of travel for a belt.

- Robotic arms: For precise positioning and limit detection of movement.

- Machine safety guards: To ensure guards are correctly positioned before machinery operates.

- Elevators and hoists: To prevent over-travel and ensure proper door operation.

- Consumer Electronics:

- Computer mice and keyboards: For button clicks.

- Vending machines: For coin detection or jam detection.

- Medical Equipment:

- In various diagnostic tools and surgical instruments for precise control.

- Pin Plunger: A simple button-like plunger that is directly pressed.

- Roller Lever: Features a lever with a roller at the end, ideal for applications with sliding or rotating components.

- Hinge Lever: A simple lever arm that pivots to actuate the switch.

- Flexible Roller: Similar to a roller lever, but with a more flexible arm to accommodate irregular surfaces or wider ranges of motion.

- Spring Plunger: A plunger supported by a spring, allowing for a certain degree of "overtravel" beyond the actuation point without damaging the switch.

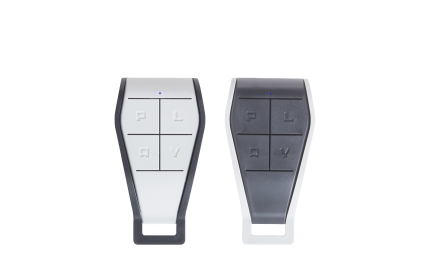

Original Gate Opener Remote Control

Ship or pick up from our office.

Original Gate Opener Remote Control

*433 MHz *2-4 Buttons *(More than 10 different designs)A gate opener remote is a handheld device that allows you to remotely open and close an automatic gate.

It sends a radio signal to a receiver connected to the gate's motor, triggering the gate to move. These remotes are a convenient way to control access to properties, especially when entering or exiting with a vehicle.

Here's a more detailed explanation:

-

Function:The remote transmits a radio signal to a receiver unit connected to the gate opener motor.

-

Convenience:They eliminate the need to manually open or close the gate, providing convenience and security.

-

Compatibility:Remotes must be compatible with the gate opener's frequency and coding system.

-

Types:There are various types of remotes, including single-button (for basic open/close) and multi-button (for more complex functions like stopping or partially opening the gate).

-

Programming:Remotes need to be programmed to work with the specific gate opener.

-

Frequency:Most gate openers use 433.92 MHz frequency, but some older systems might use different frequencies.

-

Range:The range of the remote can vary depending on obstructions like trees or buildings.

Pedestrian gate electric lock

Ship or pick up from our office.

Pedestrian gate electric lock

*DC12 V A pedestrian gate electric lock is a device that uses electrical power to secure a walk-through gate, offering enhanced security and convenience compared to traditional manual locks. These locks are commonly used in residential, commercial, and community settings, often integrated with access control systems. Here's a breakdown of what they are and how they work: How they work:- Electronic Control: The locking mechanism is controlled electronically. This allows it to be locked and unlocked automatically, typically triggered by an access control system.

- Access Control Integration: They can be linked to various access control devices, such as:

- Keypads: Users enter a code to unlock the gate.

- Remote controls: Wireless remotes allow for convenient opening from a distance.

- Intercoms: Visitors can communicate with occupants, who can then grant access.

- Key fobs/Card readers: Users can simply tap or swipe a fob/card to unlock.

- Push buttons: For easy exit from the inside.

- Telephone entry systems: Allowing access via phone.

- Types of Electric Locks:

- Electromechanical Locks: These use an electric impulse to trigger a mechanical latch or bolt to engage or disengage. They are known for their strength and durability, suitable for both indoor and outdoor use.

- Electromagnetic Locks (Maglocks): These consist of an electromagnet mounted on the gate frame and a strike plate on the gate itself. When power is applied, the electromagnet creates a strong magnetic force that holds the gate closed. To unlock, the power to the magnet is simply cut. They offer a high holding force and have no moving parts to wear out.

- Enhanced Security: They provide a higher level of security than manual locks, preventing forced entry and ensuring the gate remains closed, especially in high-wind conditions.

- Automatic Locking/Unlocking: Many models automatically lock when the gate closes and unlock when activated, eliminating the need for manual locking.

- Convenience: Remote operation, keypads, and other access control options make entry and exit much more convenient.

- Versatile Applications: Suitable for a variety of pedestrian gate types (wood, steel, vinyl, etc.) and environments, including driveways, pool areas, playgrounds, and commercial perimeters.

- Fail-Secure vs. Fail-Safe:

- Fail-Secure: The lock remains locked when power is lost. This is common for high-security applications where maintaining security during a power outage is crucial.

- Fail-Safe: The lock unlocks when power is lost. This is often used in safety applications where immediate access is needed during emergencies or power failures.

- Battery Backup: Many systems include a battery backup to ensure continued operation during power outages.

- Manual Override: Most electric locks come with a key for manual release, providing a backup in case of power failure or system malfunction.

- Integration: They can be easily integrated with existing gate openers, timers, and other smart home or security systems.

Pedestrian gate electric lock with remote control

Ship or pick up from our office.

Pedestrian gate electric lock with remote control

* Two remote controls included *DC 12 V pedestrian gate electric lock with a remote control is a security system that allows you to lock and unlock a walk-through gate using an electrical mechanism, typically activated by a remote control. This provides convenience and enhanced security, as you don't need a physical key to open the gate. Here's a breakdown of what it entails: How it Works:- Electric Lock Mechanism: Instead of a traditional manual deadbolt or latch, an electric lock uses an electrical impulse to control a bolt or latch. This impulse can come from a control board connected to various access control devices.

- Remote Control Activation: A key component is the remote control, which sends a wireless signal (radio frequency) to a receiver connected to the lock's control system. When the signal is received and recognized, the lock is instructed to engage (lock) or disengage (unlock).

- Integration with Gate Systems: These locks are often integrated with automatic gate openers or access control systems. When the gate closes, the lock can automatically engage, and when a remote signal is given, it disengages to allow the gate to open.

- Power Source: Electric locks require a power source, typically low voltage (e.g., 12V DC). Many systems include a battery backup to ensure continued operation during power outages.

- Solenoid Locks: These use an electromagnet to extend or retract a bolt, securing or releasing the gate.

- Electromagnetic Locks (Mag Locks): These consist of an electromagnet mounted on the gate frame and a metal strike plate on the gate itself. When power is applied, the electromagnet creates a powerful magnetic force that holds the gate shut. Removing power releases the lock.

- Electric Strikes: These replace the standard strike plate on the gate frame. They contain a solenoid that, when activated, pivots or retracts to release the gate's latch. They are often combined with a traditional keyed doorknob or lever.

- Remote Operation: The primary benefit, allowing you to open or close the gate from a distance.

- Automatic Operation: Many models automatically lock when the gate closes, improving security.

- Fail-Safe vs. Fail-Secure:

- Fail-Secure: The lock remains locked when power is lost. This is common for high-security applications where you want the gate to stay secure even during a power outage.

- Fail-Safe: The lock unlocks when power is lost. This might be preferred for safety reasons, ensuring an exit path in an emergency.

- Holding Force: This indicates the strength of the lock in resisting forced entry, measured in pounds (lbs).

- Compatibility: Ensure the electric lock is compatible with your specific gate type (wood, metal, swing, etc.) and any existing or planned access control systems (keypads, intercoms, smart home systems).

- Manual Override: Many electric locks include a manual release key or mechanism for use in case of power failure or remote control malfunction.

- Durability and Weather Resistance: Given that they are outdoors, look for locks built with durable, weather-resistant materials.

- Integration with Other Access Control: Beyond remote controls, these locks can often be integrated with:

- Keypads (for code entry)

- Intercom systems (audio/video communication and remote release)

- Smartphone apps (for remote monitoring and control)

- Biometric readers (fingerprint, face scan)

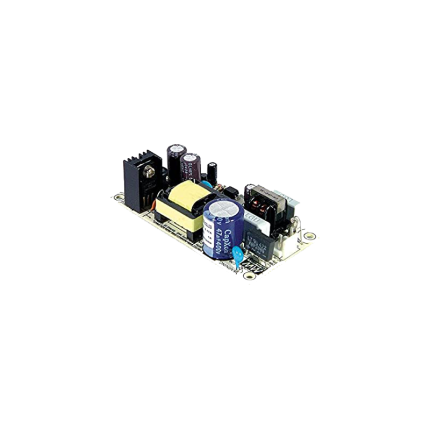

Power converter – AC 24 V to DC 12 V

Ship or pick up from our office.

Power converter - AC 24 V to DC 12 V

A power converter - AC 24 V to DC 12 V is a device that transforms alternating current (AC) at 24 volts into direct current (DC) at 12 volts. These are also commonly referred to as AC/DC power adapters or rectifiers. How it Works ⚙️ The conversion process from AC to DC typically involves several key stages:- Step-Down Transformer: The 24V AC input first goes through a transformer. This component reduces the voltage from 24V AC to a lower AC voltage, although not necessarily directly to 12V DC at this stage. It's about getting to a more manageable voltage level for the subsequent steps.

- Rectification: The reduced AC voltage then enters a rectifier circuit, usually made of diodes. Diodes allow current to flow in only one direction, effectively converting the alternating current (which periodically reverses direction) into a pulsating direct current (which flows in one direction but isn't smooth).

- Half-wave rectifiers block half of the AC waveform.

- Full-wave rectifiers (like a bridge rectifier) use both halves of the AC waveform, resulting in a smoother, more efficient conversion.

- Smoothing (Filtering): The pulsating DC output from the rectifier isn't perfectly steady. It has "ripples" or fluctuations. To smooth this out, capacitors are used. These components store electrical energy during the peaks of the waveform and release it during the dips, creating a much more stable and continuous DC voltage.

- Voltage Regulation: Finally, a voltage regulator circuit ensures that the output voltage remains consistently at the desired 12V DC, regardless of minor fluctuations in the input AC voltage or changes in the load connected to the converter. This also helps protect the connected device from voltage spikes or drops.

- CCTV cameras and surveillance systems: Many security cameras operate on 12V DC, and these converters allow them to be powered from a 24V AC power supply (which is often used in larger installations for longer cable runs due to less voltage drop).

- Low-voltage lighting: Converting 24V AC to 12V DC for certain LED lights or other low-voltage lighting systems.

- Industrial control systems: Some industrial equipment or sensors might use 12V DC power while the facility's power supply is 24V AC.

- Automotive accessories (with specific input needs): While most car systems are 12V DC, there might be niche applications where a 24V AC source needs to be converted.

- Various electronic projects and devices that require a stable 12V DC supply from an AC input.

Programmable timer relay

Ship or pick up from our office.

Programmable timer relay

A programmable timer relay is an electronic device that combines the functions of a timer and a relay, allowing users to set specific time delays for switching electrical circuits on or off. Essentially, it acts as an automated switch that operates based on pre-programmed time intervals. This enables the automation of various processes and equipment across a wide range of applications. How it Works Programmable timer relays incorporate internal circuitry (often microcontrollers or digital logic chips) that allow for precise timekeeping and control. Here's a general overview of how they function:- Control Signal: The programmable timer relay receives an input or "trigger" signal, which initiates the timing process. This signal can come from a switch, sensor, or another control device.

- Timing Mechanism: Once the signal is received, the internal timing mechanism begins to count down or up based on the programmed parameters.

- Delay Period: During this delay, the relay's contacts remain in their initial state (either normally open or normally closed).

- Contact Switching: Once the programmed delay period elapses, the relay's contacts change state, either closing to allow current to flow or opening to interrupt it.

- Maintaining State & Resetting: The relay maintains its new state until the input signal is removed, or a reset function is triggered. Programmable relays offer various timing modes, such as:

- On-delay: The relay activates after a set delay once the input signal is applied.

- Off-delay: The relay deactivates after a set delay once the input signal is removed.

- Interval: The relay activates for a set period and then deactivates.

- Cyclic: The relay repeatedly alternates between on and off states for specified durations.

- Industrial Automation: They control the sequencing of machinery, conveyor belts, pumps, and other equipment in manufacturing processes, ensuring precise timing and preventing system overloads.

- Lighting Control: Used in homes, commercial buildings, and street lighting to turn lights on and off at specific times or based on ambient light levels, optimizing energy consumption and security.

- HVAC Systems: Regulate fan operations, compressor cycles, and defrost cycles in heating, ventilation, and air conditioning systems to maintain desired temperatures and reduce energy use.

- Security Systems: Implement delays for door locks, alarm systems, and surveillance cameras, allowing for controlled access and scheduled activation/deactivation.

- Pump Control: Manage water pumps, sewage pumps, and sump pumps, ensuring they operate only when needed, which conserves water and prevents pump damage.

- Home Automation: Automate various household appliances like irrigation systems, washing machines, and dishwashers.

- Vehicle Systems: Control functions like intermittent windshield wipers and turn signals.

- Versatility and Customization: They can be programmed for various timing functions and sequences within a single unit, offering great flexibility for diverse applications.

- Energy Savings: By automating on/off cycles and ensuring equipment runs only when necessary, they help reduce energy consumption and costs.

- Increased Efficiency: They enable automated control of equipment and processes, improving overall operational efficiency and reducing the need for manual intervention.

- Reduced Components and Wiring: By integrating multiple timing and switching functions into one device, they can replace several individual timers and relays, simplifying wiring, reducing component inventory, and saving space in control panels.

- Cost-Effectiveness: For simpler automation tasks, they offer a more economical solution compared to full-fledged PLCs.

- Ease of Use: Many programmable timer relays feature user-friendly digital interfaces or software, making them relatively easy to configure without requiring extensive programming knowledge.

- Precise Time Control: They offer high temporal precision, with delays ranging from milliseconds to several hours.

- Troubleshooting: Integrated displays often provide alarm messages and I/O status, simplifying troubleshooting.

Programmer module -Key Automation 900DYL

Ship or pick up from our office.

PRODUCT SHEET PDFProgrammer module -Key Automation 900DYL

*REMOTE LCD CONTROLLER *Display module cable length: 120 cmThe Key Automation 900DYL is a programming module used to configure and customize the settings of Key Automation 14A control units, commonly found in sliding and swing gate openers.

It allows installers to adjust parameters and settings of the gate automation system, such as torque, tension, and auto-close features. It also facilitates the addition of new remote controls.

Here's a more detailed breakdown:

-

Programming Module:The 900DYL is a specific programmer designed for the Key Automation 14A control board.

-

Customization:It enables adjustments to various settings of the gate opener, including speed, force, and other operational parameters.

-

Remote Control Integration:The programmer allows installers to add and configure new remote controls for the gate opener.

-

Emergency Release:In case of a power failure, the 900DYL, in conjunction with the gate opener, provides an emergency release mechanism.

-

Applications:It's used with both sliding and swing gate operators, and it's compatible with the 14A control unit.