driveway gates

Relay Mini PCB 5-Pin 10A

Ship or pick up from our office.

Relay Mini PCB 5-Pin 10A

A Relay Mini PCB 5-Pin 10A is a compact, electromechanical switch designed to be mounted directly onto a printed circuit board (PCB). It uses a small control voltage to switch a larger current, making it useful for isolating control circuits from power circuits or for switching higher-power loads with a low-power signal. Key Features and Specifications- Mini: This indicates its small physical size, making it suitable for applications where space is limited.

- PCB: This means it's designed for Printed Circuit Board mounting. Its pins are typically configured to be soldered directly into holes on the PCB.

- 5-Pin: These five pins usually consist of:

- Two pins for the coil: These are where the control voltage is applied to energize the coil and activate the relay.

- Three pins for the contacts: These typically include a common (COM) pin, a normally open (NO) pin, and a normally closed (NC) pin.

- 10A: This is the maximum current rating that the relay's contacts can safely switch. It means the relay is capable of handling up to 10 amperes of current through its switched contacts.

- Normally Open (NO): The contact is open when the coil is de-energized and closes when the coil is energized.

- Normally Closed (NC): The contact is closed when the coil is de-energized and opens when the coil is energized.

- Automotive applications: For controlling lights, motors, and other accessories.

- Home automation: Switching lights, appliances, and HVAC systems.

- Industrial control: In PLCs (Programmable Logic Controllers) and other control panels.

- Appliance control: In washing machines, refrigerators, and microwave ovens.

- DIY electronics projects: Where low-power signals need to control higher-power devices.

RFID Tag Access Control

Ship or pick up from our office.

RFID Tag Access Control

RFID Tag Access Control is a system that uses Radio Frequency Identification (RFID) technology to manage and control access to physical spaces or logical systems. It allows only authorized individuals or items to enter secure areas by wirelessly reading data stored on RFID tags. Think of it as a modern, electronic key system where your "key" is an RFID tag (like a card or key fob) and the "lock" is an RFID reader. How it Works ⚙️ The fundamental principle is straightforward:- RFID Tag/Credential: Each authorized individual or item is assigned an RFID tag. This tag contains a microchip that stores a unique identification code and an antenna.

- RFID Reader: A reader (also called an interrogator) is installed at the access point (e.g., a door, gate, or turnstile). The reader emits radio waves.

- Communication: When an RFID tag comes within range of the reader's radio waves, the tag's antenna captures energy from the reader's signal (for passive tags) or uses its own power source (for active tags) to activate its microchip. The tag then transmits its unique data back to the reader.

- Data Processing: The reader decodes the information from the tag and sends it to a central access control software or system.

- Authentication and Decision: The software compares the tag's unique ID with a database of authorized users and their assigned permissions. If the ID is valid and the user has permission to access that specific area at that time, the system sends a signal to unlock the door, open the gate, or grant access. If not, access is denied.

- Logging: The system typically logs every access attempt (both granted and denied), providing an audit trail for security monitoring and compliance.

- RFID Tag Access Controls/Credentials: These are the physical devices carried by users. They come in various forms, such as:

- Cards: Similar to credit cards, commonly used for employee badges or hotel key cards.

- Key Fobs: Small, convenient devices attached to keychains.

- Wristbands: Often used in recreational facilities or for events.

- Stickers/Labels: Can be affixed to items or vehicles.

- Mobile Credentials: Increasingly, smartphones can act as RFID tags through NFC (Near Field Communication), a subset of HF RFID.

- RFID Readers: Devices that emit radio waves to energize and read data from RFID tags. They can be fixed (at entry points) or mobile (handheld scanners).

- Antennas: Integral to the reader (or external), they transmit and receive radio signals to and from the tags. The antenna design influences the read range and reliability.

- Access Control Software/Management System: The "brain" of the system. This software manages user databases, assigns access permissions, logs events, and allows administrators to configure and monitor the system remotely.

- Access Control Panel/Controller: Hardware that connects the readers to the central software, processing data and controlling the locking mechanisms.

- Passive RFID Tags:

- Do not have an internal power source.

- They draw power from the radio waves emitted by the reader to operate.

- Are generally smaller, less expensive, and require no maintenance.

- Have a shorter read range (a few centimeters to a few feet).

- Most commonly used in access control for cards and key fobs.

- Active RFID Tags:

- Have their own internal power source (battery).

- Can transmit data over longer distances (up to several hundred meters) and at regular intervals.

- Are larger and more expensive.

- Often used for long-range applications like vehicle tracking or asset management.

- Semi-Passive RFID Tags (Battery-Assisted Passive - BAP):

- Contain a battery to power the microchip, but still rely on the reader's signal to initiate communication.

- Offer better read range and performance than passive tags, without continuously transmitting like active tags.

- Low Frequency (LF) RFID (125-134 kHz):

- Short read range (1-10 cm).

- Less susceptible to interference from metal and water.

- Common in traditional access control systems.

- High Frequency (HF) RFID (13.56 MHz):

- Moderate read range (10 cm-1 meter).

- Widely used for access control, ticketing, and Near Field Communication (NFC) applications (like smartphone taps).

- Ultra-High Frequency (UHF) RFID (300 MHz-3 GHz, often 860-960 MHz for RAIN RFID):

- Long read range (up to 12 meters).

- More susceptible to interference from liquids and metals.

- Used in applications requiring longer read distances, such as vehicle access control or large-scale inventory tracking.

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.

UHF Label

Ship or pick up from our office.

UHF Label

A UHF (Ultra-High Frequency) label access control system uses radio-frequency identification (RFID) technology operating in the ultra-high frequency range (typically 860-960 MHz) to manage and control access to specific areas, buildings, or resources. It's a touchless, automated system that offers long-range reading capabilities and the ability to identify multiple items simultaneously, making it highly efficient for various applications like vehicle access, personnel tracking in large facilities, and event management. 🛂 How it Works The core principle of a UHF label access control system relies on the communication between RFID tags (labels) and RFID readers. Here's a breakdown of the process:- RFID Tags (Labels): These are small electronic devices, often in the form of adhesive labels, cards, or embedded devices. They contain a microchip that stores unique identification data and an antenna. Most UHF tags used in access control are passive, meaning they don't have their own power source and rely on the energy emitted by the reader.

- RFID Reader: The reader emits radio waves, creating an electromagnetic field. When a UHF RFID tag enters this field, it absorbs energy from the waves, which powers its microchip.

- Data Transmission: Once activated, the tag modulates the waves to transmit its stored data (its unique ID) back to the reader.

- Data Processing and Verification: The reader captures and decodes this data, then sends it to a central access control system (often a computer with specialized software and a backend database). The system verifies the tag's unique ID against a list of authorized credentials and pre-defined access rules.

- Access Granting/Denial: If the tag is authorized, the system sends a signal to unlock a door, open a gate, or grant access. If not authorized, access is denied, and the system may trigger an alarm or log the attempted entry.

- Logging: The system typically records all entry and exit events, providing a detailed audit trail for security and management purposes.

- UHF RFID Tags/Labels: These are the physical identifiers worn by individuals or attached to vehicles/assets. They store the unique ID and are read by the system.

- UHF RFID Readers: These devices emit radio waves to power and read the data from the tags. They are strategically installed at entry/exit points (e.g., doorways, gates). Fixed readers are common for specific zones, while handheld readers offer flexibility for mobile applications like inventory or searching for tags.

- Antennas: Connected to the readers, antennas are responsible for transmitting and receiving the radio signals. The type and placement of antennas affect the read range and coverage area.

- Access Control Software/System: This is the "brain" of the system. It manages the database of authorized tags, processes the data received from readers, applies access rules, and controls the locking mechanisms. It often integrates with other security or building management systems.

- Backend Database: Stores all the information related to RFID tags, authorized users, access levels, and event logs.

- Locking Mechanisms: These are the physical devices controlled by the system, such as electronic door locks, gate barriers, or turnstiles.

- Long Read Range 📏: UHF systems can read tags from several meters away (typically 3-10 meters, and sometimes up to 25 meters or more), allowing for hands-free and rapid access, particularly useful for vehicles or large volumes of people.

- High-Speed Data Transmission and Multi-Tag Reading ⚡: They can read multiple tags simultaneously (often over 100 tags per second), significantly improving efficiency in high-traffic areas and during events.

- Enhanced Efficiency ⏱️: Automation of access eliminates manual checks, reduces queuing times, and frees up staff for other tasks.

- Improved Security 🔒: Each tag has a unique identifier, making it difficult to forge or duplicate. The system provides real-time monitoring and detailed audit trails, enhancing accountability and security. Integration with other systems like surveillance cameras can further bolster security.

- Touchless Operation 🖐️: The long read range enables touchless access, which is beneficial for hygiene, particularly in high-traffic areas or environments where physical contact should be minimized.

- Scalability 📈: UHF RFID systems can be easily scaled to accommodate a growing number of users and access points without compromising performance.

- Durability and Resistance 💪: UHF tags are often resistant to environmental factors like water, oil, and chemicals, and the data stored on their chips is protected. They can also be reused.

- Reduced Wear and Tear: As there's no physical contact with readers, the system components experience less wear and tear, leading to lower maintenance costs.

Card Holder

Ship or pick up from our office.

Card Holder

A UHF/RFID card holder is a specialized enclosure designed to hold and protect UHF (Ultra-High Frequency) RFID cards, often used for access control, vehicle identification, and logistics.

These holders typically consist of a durable material with a slot or pocket to securely accommodate the card, and may feature a mounting mechanism like suction cups for windshield attachment.

They enable convenient and reliable use of UHF RFID cards in various applications, such as parking systems, building access, and asset tracking, by providing a designated place for the card and facilitating easy scanning by RFID readers.

UHF Tag

Ship or pick up from our office.

UHF Tag

A UHF (Ultra-High Frequency) tag access control system is a security solution that uses radio frequency identification (RFID) technology operating in the ultra-high frequency range (typically 860-960 MHz) to control and monitor entry and exit of individuals or vehicles to restricted areas. 🛂 It's an automated system that identifies an individual or object with a unique RFID tag and, based on pre-defined permissions, grants or denies access. Unlike traditional barcode systems, UHF RFID doesn't require a direct line of sight between the tag and reader, allowing for longer read ranges and the ability to read multiple tags simultaneously. How It Works A UHF tag access control system generally consists of four main components:- UHF RFID Tags: These are small electronic devices containing a microchip and an antenna. The microchip stores data, such as a unique identifier or user information. Passive UHF tags, the most common type, are powered by the electromagnetic field emitted by the reader. Active tags have their own battery, enabling longer read ranges and continuous data transmission.

- UHF RFID Readers: These devices emit radio waves to create an electromagnetic field. When a UHF tag enters this field, it absorbs energy (for passive tags) and uses it to power its microchip. The tag then modulates the waves to transmit its stored data back to the reader. Readers can be fixed at entry points (like doors or gates) or handheld.

- Antennas: Integrated with the reader, antennas are responsible for transmitting and receiving the radio signals. Their design and placement are crucial for optimizing read performance and range.

- Access Control Software/Server: This is the "brain" of the system. The reader sends the decoded tag data to the software, which compares it against a database of authorized users and their assigned access levels. If the credentials match, the software sends a signal to unlock the door, open a gate, or trigger another access action. This software also logs all access events, providing an audit trail.

- Long Read Range: UHF systems can read tags from several meters away, making them ideal for applications like vehicle access control where you don't need to stop and present a card.

- High Read Speed and Multi-Tag Reading: They can quickly read multiple tags at once, which is beneficial in high-traffic areas or for tracking numerous assets simultaneously.

- Automation and Efficiency: Automated identification eliminates the need for manual checks, speeding up entry and exit processes.

- Enhanced Security: By identifying individuals and logging access events, these systems improve security and accountability. Features like encryption and unique IDs help prevent unauthorized access and cloning.

- Durability: UHF tags are often designed to be robust and can withstand various environmental conditions, making them suitable for outdoor or industrial use.

- Scalability: Systems can be easily expanded to cover more access points or accommodate a larger number of users.

- Vehicle Access Control: Automatically granting access to parking lots, gated communities, or corporate campuses without requiring drivers to stop and swipe a card.

- Building and Room Access: Controlling entry to offices, secure areas, or sensitive facilities for employees and authorized personnel.

- Event Management: Using RFID-enabled wristbands or badges for quick and efficient entry to concerts, theme parks, or VIP areas.

- Asset Tracking: While primarily for access, the same technology can track the movement of valuable assets within a controlled environment.

- Personnel Tracking: Monitoring the presence and movement of staff within a facility for safety or operational purposes.

- Interference: Performance can be affected by certain materials like metal and liquids in the environment, which can interfere with radio waves.

- Cost: Initial installation costs can be higher compared to simpler access control methods due to the specialized hardware and software.

- Regulatory Compliance: UHF frequencies are not globally harmonized, meaning system components must comply with regional radio regulations.

- Security Risks: While secure, like any digital system, there's a potential for sophisticated cloning or hacking attempts if not properly secured with encryption and robust protocols.

Mercury Level Switch

Ship or pick up from our office.

Mercury Level Switch

A mercury level switch is a type of electrical switch that uses a small amount of liquid mercury to open or close an electrical circuit based on its position or the level of a liquid. Essentially, the mercury acts as a conductive bridge between electrical contacts. How it Works The core component of a mercury level switch is a sealed glass or metal capsule containing one or more electrical contacts and a small, free-moving drop of mercury. When the switch or the liquid it's monitoring changes its tilt or level:- Tilt Switches: Gravity pulls the mercury to the lowest point within the capsule. If the tilt is sufficient, the mercury will flow to connect two or more contacts, completing an electrical circuit. Tilting it in the opposite direction moves the mercury away, breaking the circuit.

- Float Switches: In liquid level applications, the mercury switch is often integrated with a float mechanism. As the liquid level rises or falls, the float moves, which in turn tilts the mercury switch, causing the mercury to connect or disconnect the contacts.

- Displacement Switches: Some designs use a "plunger" that dips into a pool of mercury, raising the mercury level to contact an electrode and complete the circuit.

- Thermostats: In older thermostats, they controlled heating and cooling systems.

- Sump Pumps: Used to automatically turn on the pump when water levels rise.

- Appliances: Found in washing machines (for lid switches and load balancing), chest freezers (for lid lights), and some gas appliances like ovens and water heaters (as flame sensors).

- Automotive Industry: Previously used for trunk lid lights, ride control, and anti-lock braking systems.

- Industrial Settings: Utilized in liquid level control and safety systems.

- Roll Sensing/Tip-over Warnings: For construction equipment or other vehicles operating on uneven terrain.

- Durability and Reliability: The sealed contacts prevent oxidation, leading to a long lifespan.

- Quiet Operation: No abrupt snapping of contacts.

- No Contact Erosion: Mercury's liquid nature prevents the wear and tear seen in mechanical contacts.

- Spark-Free: They don't produce sparks when making or breaking circuits, making them suitable for hazardous environments.

- Toxicity of Mercury: This is the primary and most significant disadvantage. Mercury is a highly toxic substance, posing serious environmental and health risks if released.

- Environmental Concerns: Improper disposal of mercury switches can lead to widespread contamination. Due to these concerns, the use of mercury switches has been largely phased out in many applications, especially in new products.

- Sensitivity to Gravity/Orientation: While an advantage for tilt sensing, it makes them unsuitable for portable or mobile devices where orientation changes or vibrations could cause false readings.

- Limited Functionality: Most mercury switches provide only a simple on/off function.

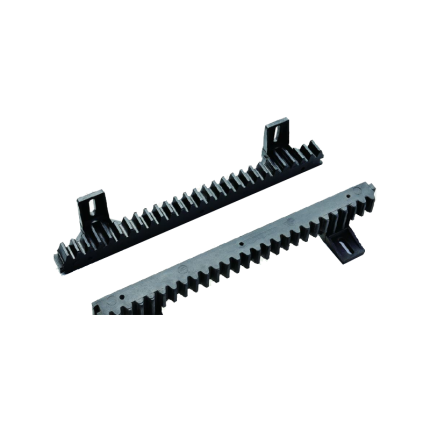

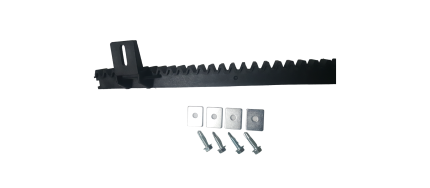

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

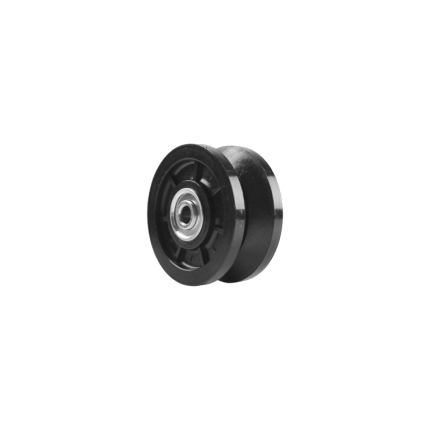

Sliding gate V-Groove nylon wheels -SLGWNS250

Ship or pick up from our office.

Sliding gate V-Groove nylon wheels -SLGWNS250

*Double bearing *Max 250 Kg *98 mm Diameter (4") x 44 mm Width (1-3/4") (Heavy-duty bolts, nuts, and washers are included)Sliding gate operator gear rack -SLGR41

Ship or pick up from our office.

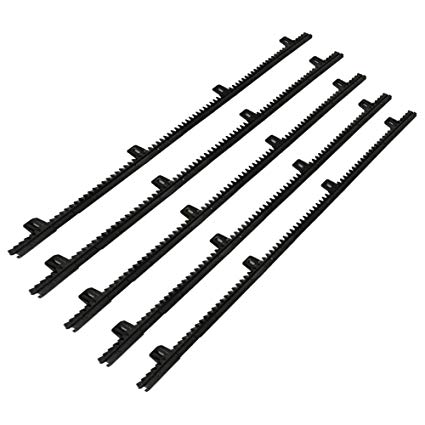

Sliding gate operator gear rack -SLGR41

*4 Holes *Length: 1018 mmSliding gate V-Groove nylon wheels -SLGWN778MLB

Ship or pick up from our office.

Sliding gate V-Groove nylon wheels -SLGWN778MLB

*Double bearing *Max 250 Kg *4" Diameter x 1-3/4" Width (Heavy-duty bolts, nuts, and washers are included)UHF Licence Plate

Ship or pick up from our office.

UHF Licence Plate

A UHF (Ultra High Frequency) Licence Plate access control system is a vehicle identification and access management solution that uses UHF RFID (Radio Frequency Identification) technology to automatically grant or deny entry to vehicles. Instead of relying on traditional license plate recognition (ANPR/LPR) which uses cameras to read visible plates, UHF systems use RFID tags, often in the form of stickers or cards, affixed to vehicles. 🚗 When a vehicle with a registered UHF RFID tag approaches an access point (like a gate or barrier), a UHF reader emits radio waves. The tag, powered by these waves, transmits its unique identification data back to the reader. This data is then sent to an access control system which verifies the vehicle's authorization. If authorized, the system triggers the gate to open, allowing for fast, hands-free, and seamless entry and exit. This technology is widely used in places requiring efficient and secure vehicle flow, such as:- Gated communities 🏡

- Parking facilities (corporate, commercial, residential) 🅿️

- Industrial sites and logistics hubs 🏭

- Toll roads 🛣️

- UHF RFID Tags: These are small, passive (battery-less) or semi-active devices that contain a microchip storing a unique identification number and an antenna. They are typically affixed to the vehicle's windshield or license plate. When exposed to radio waves from a reader, the tag's antenna collects energy, powering the microchip to transmit its data.

- UHF RFID Readers: These devices are installed at access points (e.g., gate entrances) and emit radio waves to detect and read the RFID tags on approaching vehicles. They have antennas to send and receive signals, and a processor to decode the data from the tags. UHF readers typically have a longer read range (up to 10-12 meters or more) compared to other RFID frequencies, allowing vehicles to pass without fully stopping.

- Access Control System (Software/Controller): This is the "brain" of the system. The reader sends the tag's ID number to this system. The access control software then compares this ID with its database of authorized vehicles. Based on pre-defined criteria (e.g., specific times of day, authorized user groups), it determines whether to grant or deny access.

- Barrier/Gate System: If access is granted by the control system, a signal is sent to the physical barrier (like a boom gate or sliding gate), which opens to allow the vehicle to pass.

- Speed and Efficiency 🚀: Vehicles don't need to stop or roll down windows, significantly reducing traffic congestion, especially during peak hours. This provides a "frictionless" entry experience.

- Long Read Range 📏: UHF RFID allows for detection from several meters away, enabling quick processing of vehicles even at higher speeds.

- Reliability in Diverse Conditions 🌧️☀️: Unlike optical ANPR systems that can be affected by dirt, rain, snow, or poor lighting, UHF RFID tags are generally more robust and less susceptible to environmental factors.

- Enhanced Security 🔒: RFID tags are difficult to duplicate or tamper with, offering a higher level of security than some other methods. The system also logs all entries and exits, providing a clear audit trail.

- Reduced Operational Costs 💰: Automation minimizes the need for manual gate attendants, leading to lower labor costs over time. There's also no need for physical cards or key fobs that can be lost or damaged, saving on replacement costs.

- Integration Capabilities 🔗: These systems can often integrate seamlessly with other security and management platforms, such as visitor management systems, surveillance cameras, and parking management software, for a comprehensive solution.