For the BFT Deimos range of sliding gate operators, the main control board is typically the BFT Merak control unit. There are different versions, most commonly the

Merak SL1 and

Merak SL2, and sometimes an older

QSC board.

Here's a breakdown of the BFT Merak control board for Deimos operators:

Key Features and Characteristics of BFT Merak Control Boards (for Deimos):

- Integrated Control Unit: The control board is usually incorporated directly within the Deimos operator casing, making for a compact and self-contained unit.

- LCD Display (for newer models): Modern Merak boards (like Merak SL1 and SL2) feature an LCD display. This significantly simplifies programming, configuration, and diagnostics by providing clear menu options and error messages. Older QSC boards used a combination of LEDs for diagnostics.

- Built-in Receiver: Most Merak control boards have a two-channel rolling code radio receiver integrated. This allows for direct compatibility with BFT remote controls like the Mitto series (e.g., Mitto2, Mitto4).

- D-Track Technology: This is a core BFT technology present in Merak boards. D-Track is an intelligent torque management system that constantly monitors the gate's force and movement. It detects obstacles by identifying even slight variations in motor force due to temperature changes or wear. This ensures optimal safety by immediately reversing the gate's movement upon obstruction and helps with legal compliance for safety certifications.

- 24V Technology: Many BFT Deimos operators, and consequently their Merak control boards, operate on 24V technology. This offers several benefits:

- Safety: Lower voltage is inherently safer.

- Precise Control: Allows for precise adjustment of slowdown during opening and closing cycles.

- Intensive Use: Suitable for high-frequency use, including residential and light commercial applications.

- Battery Backup: Often allows for the integration of battery backup systems (e.g., BFT SLBAT2) for continued operation during power outages.

- Self-Learning and Self-Diagnostic Functions: The control unit can "learn" the gate's opening and closing limits during initial setup and perform self-diagnostics to identify potential issues, often indicated via the LCD display or LED codes.

- Safety Device Management: The Merak board manages various safety devices, including:

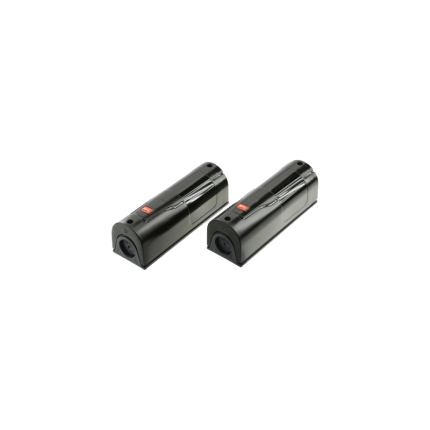

- Photocells: Connects to safety photocells (e.g., Compacta A20-180) that detect objects in the gate's path, triggering a stop or reversal.

- Obstacle Detection: As mentioned with D-Track, it's designed to detect obstacles and reverse motion to prevent damage.

- Programmable Functions: Offers a wide range of customizable settings, such as:

- Automatic closing time.

- Pedestrian passage mode.

- Slowdown in opening and closing.

- Quick closing.

- Maintenance warnings.

- Magnetic Limit Switches (for "Ultra" models): The "ULTRA" versions of Deimos operators (e.g., Deimos Ultra BT A400/A600) typically use magnetic limit switches for more precise and reliable end-of-stroke detection compared to traditional electromechanical microswitches.

- U-Link Connectivity (for advanced models): Some advanced Merak boards and Deimos models are compatible with BFT's U-Link communication protocol. This allows for more advanced integration with other BFT devices, wireless connections, and even cloud-based monitoring and diagnostics via specific gateways (B-Eba).

Common Issues and Troubleshooting for BFT Deimos Control Boards:

While generally reliable, control boards can experience issues. Some common problems and troubleshooting steps include:

- Blown Fuses: Often indicated by no power to the keypad or control board. A short circuit (e.g., a faulty flashing beacon, wiring issue) can cause fuses to blow. Identifying and fixing the short is crucial before replacing the fuse.

- Photocell Errors: Displayed as error codes (e.g., "PHCL" or "ER04"). This can be due to misaligned, dirty, or faulty photocells, or wiring issues to the photocells.

- Gate Not Opening/Closing or Random Operation: Can stem from power supply issues, remote control problems (dead batteries, interference, reprogramming needed), obstructions, or indeed, a faulty control board.

- Motor Not Working: Could be power failure, motor overheating, or a burnt-out motor.

- Gate Does Not Stay Closed: Malfunctioning limit switch or a faulty control board.

Maintenance and Replacement:

- Regular maintenance, including keeping photocells clean and checking wiring, can prevent many issues.

- If a control board is suspected to be faulty, it's recommended to consult a qualified technician. Replacement boards are available as spare parts.

In summary, the BFT Merak control board is the sophisticated brain behind the BFT Deimos sliding gate operators, providing advanced features for safety, programming, and reliable operation.