Main considerations for the design of automatic gates

One of the most important considerations regarding the main considerations for the design of automatic gates is the weight of each gate leaf.

A heavier gate needs a stronger force to open and close it. But this doesn’t just mean the force needed to overcome the inertia of the gate itself.

The gate will be affected by air pressure on its moving face and this can vary greatly depending on the speed of any wind blowing towards a moving gate.

As you increase the force required to move a gate, you are increasing the potential force passed to anything coming into contact with that moving gate.

Gate automation motor choices are also important. Pushing the gate open from as far from the hinge as possible requires less force. Ram motors and articulated arm gate motors push and pull the gate further from the hinge than underground motors. This means that they require less force to move the same gate than an underground motor does.

Articulate arm motors also present a risk due to their design. The articulated arm creates a gap between itself, the gate post or pillar, and the closed gate. As the gate is closed, this gap closes up.

The hinge end of swing gates creates a gap between the gate and the post, which must not be big enough for anyone to put their arm or leg through. As the gate opens, the gap between the gate and the mounting can close up.

Sliding gates with open spaces in their design can create risks if they slide open against railings. The leading edge of a sliding gate can also create risks when it slides past posts, pillars, edges of walls, etc.

Any safe automated gate system should include a manual release that disconnects the motors and allows gates to be moved by hand. All users of the gates should be taught how to use the system and where manual release keys are kept.

Risk Assessment

Your gate automation installer should deal with all the potential risks with a thorough safety audit. This looks at each potential risk in conjunction with how the gate will be used.

Your installer should bring the proposed gate design, choice of the gate automation system, and user knowledge together.

They should then apply the Standards and recommendations to design a safe gate automation system for you.

Typically, a thorough risk assessment includes the following:

Step 1: How the gate will be used

Step 2: The potential risks throughout the lifetime of the system

Step 3: How dangerous each potential risk is and what needs to be done to mitigate that risk

This allows the risks to be prioritized and dealt with in the following ways:

a: The risk is eliminated or reduced by the design of the gate automation system.

b: The risk is reduced by the application of safety devices added to the system.

c: Where it is not possible to incorporate a or b, warning signs and safety instructions are provided clearly for all users of the electric gates

d: Measures for fast and safe release from the hazard are incorporated.

A gate automation system can be dangerous if designed and installed by unqualified, inexperienced, or uncaring gate automation engineers. However, safe automatic gate systems are installed every day all over the world by professional installers.

When you’re looking for a gate installer, use this article to help you ask them questions about gate safety.

Make sure you have an installer who understands the risks, talks to you about your use of the gates, and applies the recommended risk prevention measures.

Royal Electronics Technology Center Corporation (Royal Gate) is the best choice to have the best Electric Gate.

We have many different sample gate designs that are viewable on our website.

Each design with special dimensions is different from the others, and we have some suitable gate opener packages for each one.

We have lots of different brands, models, and capacities of driveway gate operators and accessories in our stock, and we can give you our best recommendations, based on your chosen type, design, and dimensions of your driveway gate.

If you are interested in having a safe automatic gate installed on your property, Royal Gate is with you step by step.

Designing, fabricating, installing, and repairing automatic driveway gates is our main business.

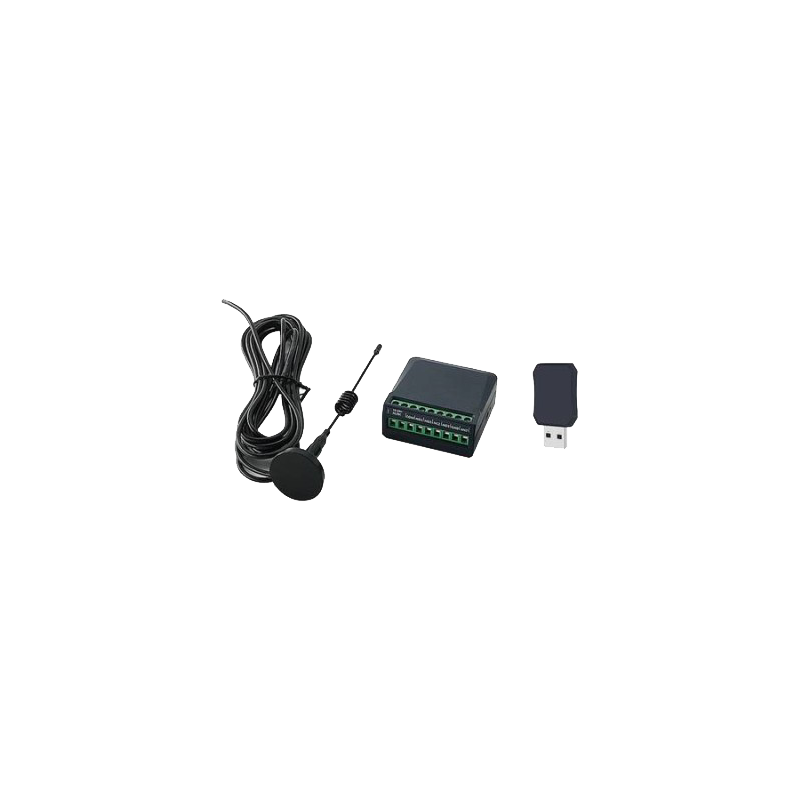

Also, we install smart access control systems for the automatic driveway gates.

By using this system, you can open and close your sliding gate or your swing gate by using your smartphone.

Main considerations for the design of automatic gates

–> To have in-site technical services:

- If you have an account with us, please send your request directly from your customer panel.

- Please click here to send your information and request directly to our customer hub, and let us know your preferred dates to schedule a visit.

- If you are in Greater Vancouver, BC, our technician will come to your address and resolve the problem.

- To have on-site technical services for your installed automatic driveway gate, if you have an account with Royal Gates, please send your request directly from your customer’s panel.

- If this is your first service request, and looking for our recommendations, please send some pictures from the gate operator, main control panel, and receivers or your remote control to us using WhatsApp at 778 384 2800 or by email to retcc.ca@gmail.com.

- You can click here to send your information and request directly to our customer hub, and let us know your preferred dates to schedule a visit.

- You will be contacted within one business day.

–> To get an estimate for your required driveway gate, you can click on “Fast Estimate”.

- If you want to continue please submit the form, your request will directly come to our customer hub and we will make contact with you, within a maximum of one business day.

- To create a custom quote, need more information like design, dimensions, your address, name, and email.

- You can click here to send your information and request directly to our customer hub, and let us know your preferred dates to schedule a visit (If necessary).

- If you are in Greater Vancouver, BC, our technician will come to your address.

- Please send some pictures of the driveway, posts, and the electric sources to us using WhatsApp at 778 384 2800 or by email to retcc.ca@gmail.com.

- You can click here to send your information and request directly to our customer hu,b and let us know your preferred dates to schedule a visit.

- You will be contacted within one business day.

If your location is out of the BC, you can send some pictures from your driveway gate, and the operator by text message or email and call us to get our technician’s suggestions to resolve the issue on your driveway gate opener.

Royal Electronics Technology Center Co (Royal Gates) using the best gate automation technicians can repair the driveway gate operators.

Our main service area is in Vancouver BC Canada.

Victoria Island, Duncan, Gibsons, Nanaimo, Sechelt, Tofino, Port Alberni, Qualicum Beach, Parksville, Vancouver, West Vancouver, North Vancouver, Richmond, Burnaby, New Westminster, Surrey, Delta, White Rock, Coquitlam, Port Coquitlam, Anmore, Langley, Maple Ridge, Pitt Meadows, Abbotsford, and Chilliwack in British Columbia are our services areas.

For more information on the installation methods and our previous project regards to “How to Install an Automatic Gate” please visit our YouTube channel.