Shop

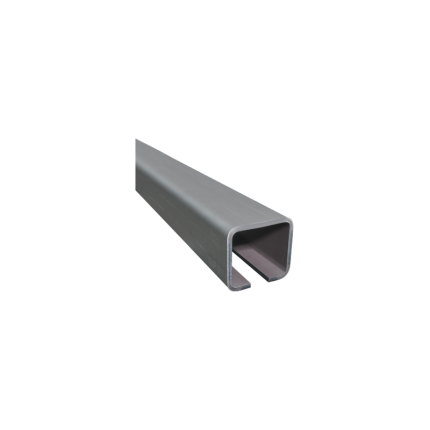

Cantilever sliding gate track

Ship or pick up from our office.

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

Relay 5-Pin 40A

Ship or pick up from our office.

Relay 5-Pin 40A

A 5-pin 40A relay is an electromechanical switch commonly used in automotive and other applications. It allows a low-power electrical signal to control a higher-power circuit. The "5-pin" refers to the number of terminals it has, and "40A" indicates that its contacts can safely handle a maximum current of 40 amps. How it Works A relay essentially functions like a remote-controlled switch. It has two main circuits:- Control Circuit (Coil): This low-power circuit energizes an electromagnet inside the relay.

- Switched Circuit (Contacts): This high-power circuit is controlled by the electromagnet, either opening or closing connections to a device.

- Pins 85 and 86: These are the coil terminals. When a small current (typically 12V DC in automotive applications) is applied across these pins, it creates a magnetic field.

- Pin 30: This is the common terminal for the switched circuit. It's usually connected to the main power source (e.g., battery) through a fuse.

- Pin 87: This is the Normally Open (NO) contact. When the relay coil is energized, pin 30 connects to pin 87, allowing current to flow to the connected device.

- Pin 87a: This is the Normally Closed (NC) contact. When the relay coil is not energized, pin 30 is connected to pin 87a. When the coil is energized, this connection breaks.

- High-Current Control: They allow you to control high-current devices (like headlights, fuel pumps, or cooling fans) with a low-current switch. This protects the sensitive, smaller switches from being damaged by excessive current.

- Reduced Voltage Drop: By placing the relay closer to the high-current device and power source, you can use shorter runs of heavier gauge wire for the high-current circuit, minimizing voltage drop and ensuring the device receives adequate power.

- Safety: They isolate high-current circuits from the passenger compartment, enhancing safety.

- Automotive: Headlights, fog lights, horns, fuel pumps, electric cooling fans, power windows, central locking, and various aftermarket accessories.

- Industrial Control: Switching motors, solenoids, and other heavy-duty equipment.

- General Purpose: Any application where a low-power signal needs to control a higher-power circuit.

- Pin 85: Connect to ground (-).

- Pin 86: Connect to the positive (+) side of your control switch. When this switch is activated, it provides power to the coil.

- Pin 30: Connect directly to the positive (+) terminal of your battery, always through an appropriately sized fuse.

- Pin 87: Connect to the positive (+) terminal of the device you want to power when the relay is activated (Normally Open connection).

- Pin 87a: (Optional) Connect to a device you want to power when the relay is not activated (Normally Closed connection).

Micro Limit Switch

Ship or pick up from our office.

Micro Limit Switch

A micro limit switch, often simply called a micro switch, is a type of electrical switch that's characterized by its small size and the precise, rapid action it takes when a minimal amount of force is applied to its actuator. It's designed to detect the presence or position of an object or the end of a mechanical movement. These switches are known for their:- High sensitivity: They require very little force to activate.

- Rapid response: The internal contacts "snap" open or closed very quickly, regardless of how slowly the actuator is pressed. This snap-action mechanism helps to reduce arcing and extends the switch's lifespan.

- Reliability: They are built to withstand millions of operations, making them durable for long-term use.

- Compact size: Their small footprint allows them to be used in applications where space is limited.

- Actuator: This is the external part that an object or mechanical component presses against. It can be a button, a lever (with or without a roller), a plunger, or other forms.

- Internal spring mechanism: This provides the "snap-action." When the actuator is pressed to a certain point (the "trip point"), the spring mechanism rapidly moves the contacts.

- Contacts: These are the electrical components that open or close the circuit. Micro switches usually have three terminals:

- Common (C): The input terminal.

- Normally Open (NO): This contact is open (no current flows) when the switch is unactivated and closes when the switch is actuated.

- Normally Closed (NC): This contact is closed (current flows) when the switch is unactivated and opens when the switch is actuated

- Household Appliances:

- Microwave ovens: To detect if the door is closed before operating.

- Washing machines: For door interlocks and water level detection.

- Refrigerators: To turn the light on/off when the door opens/closes.

- Printers: To detect paper jams or the position of paper.

- Automotive Industry:

- Car doors: To detect if a door is open or closed (e.g., for interior lights or security systems).

- Brake pedals: To activate brake lights.

- Seat belt mechanisms: To detect if a seat belt is fastened.

- Industrial Automation:

- Conveyor systems: To detect the presence of items or the end of travel for a belt.

- Robotic arms: For precise positioning and limit detection of movement.

- Machine safety guards: To ensure guards are correctly positioned before machinery operates.

- Elevators and hoists: To prevent over-travel and ensure proper door operation.

- Consumer Electronics:

- Computer mice and keyboards: For button clicks.

- Vending machines: For coin detection or jam detection.

- Medical Equipment:

- In various diagnostic tools and surgical instruments for precise control.

- Pin Plunger: A simple button-like plunger that is directly pressed.

- Roller Lever: Features a lever with a roller at the end, ideal for applications with sliding or rotating components.

- Hinge Lever: A simple lever arm that pivots to actuate the switch.

- Flexible Roller: Similar to a roller lever, but with a more flexible arm to accommodate irregular surfaces or wider ranges of motion.

- Spring Plunger: A plunger supported by a spring, allowing for a certain degree of "overtravel" beyond the actuation point without damaging the switch.

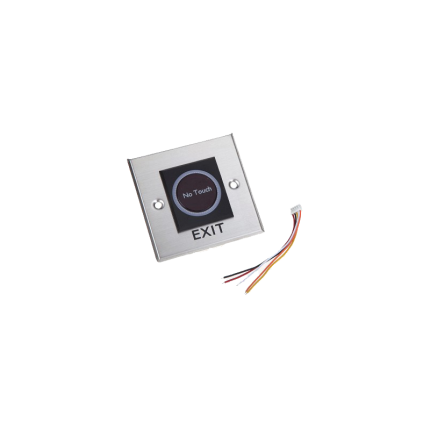

Doorbell SDB111

Ship or pick up from our office.

Doorbell SDB111

The "Doorbell SDB111" primarily refers to a wired doorbell system that operates on a 12-volt DC power supply. It's often associated with Royal Electronics Technology Center Co. and is commonly used for security access control in homes, offices, and other buildings. Here's a breakdown of its typical characteristics about the doorbell SDB111:- Wired System: The "12V" in its name signifies that it's a wired doorbell, meaning it connects to a power source via electrical wires. This usually involves a transformer that converts household voltage to 12V DC.

- Low Voltage: Like many doorbell systems, it operates on low voltage for safety.

- Functionality: Its primary function is to produce a chime sound (like a "ding-dong") when the doorbell button is pressed. It's often chosen for its durability and continuous function without needing battery replacements.

- Installation: These doorbells can be installed with screws or double-sided adhesive tape and typically come with wiring diagrams.

- Security Integration: They are considered a good security measure as they are external and can be integrated with other security systems.

- Access Control: The SDB111 is specifically mentioned in the context of access control systems, suggesting its use in managing entry to a property.

Sliding gate operator gear rack -SLGR612

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR612

*6 Holes *Length: 1018 mmCar alarm shock sensor

Ship or pick up from our office.

Car alarm shock sensor

A car alarm shock sensor is a critical component of a vehicle's security system designed to detect physical impacts or vibrations to the car. Its primary purpose is to trigger the alarm if someone attempts to break into the vehicle, tamper with it, or even tow it away. How it Works: The core principle behind a shock sensor is that it measures the intensity of vibrations or impacts. Most modern shock sensors are piezoelectric or electromagnetic, and they typically work in a dual-stage manner to reduce false alarms:- Detection of Vibration/Impact:

- When the car experiences a physical disturbance (e.g., a window being hit, someone trying to pry open a door, a car next to it bumping it, or even a strong bass from a passing vehicle), the shock sensor registers this as a vibration or impact.

- Internally, the sensor often contains a small weight or a piezoelectric crystal that moves or generates a voltage when subjected to mechanical stress. This movement or voltage change is converted into an electrical signal.

- Sensitivity Adjustment and Dual-Stage Triggers:

- Modern shock sensors are usually adjustable in terms of sensitivity. This is crucial to prevent false alarms from minor disturbances (like a loud truck passing by or someone lightly tapping the car).

- Many high-quality sensors are dual-stage or multi-stage:

- Light Impact (Pre-warning/First Stage): If a minor impact or vibration is detected (e.g., someone bumps the car, or a strong wind rattles it), the sensor sends a "pre-warning" signal to the alarm control unit. This typically results in a short series of chirps from the alarm or a warning flash of the lights. This is designed to deter a potential intruder without fully setting off the alarm.

- Heavy Impact (Full Alarm/Second Stage): If a more significant impact or sustained vibration is detected (e.g., a window being smashed, a door being forced open, or the vehicle being jacked up for wheel theft), the sensor sends a "full alarm" signal. This triggers the main alarm, sounding the siren, flashing the lights, and potentially sending an alert to the owner's remote or smartphone.

- Single-Stage: Triggers the full alarm for any detected shock above a certain threshold. (Less common in modern systems due to false alarm potential).

- Dual-Stage (or Dual-Zone): As described above, offers a warning chirp for light impacts and a full alarm for heavy impacts. This is the most common and effective type.

- Digital Shock Sensors: These are more advanced, using microprocessors to analyze the vibration patterns. They can often differentiate between different types of impacts (e.g., a window break vs. a passing truck) and are less prone to false alarms.

- Integrated with Other Sensors: Some advanced alarm modules now combine shock sensing with other functions like tilt sensing (to detect towing) or even glass-break detection (listening for the specific sound of breaking glass) into a single unit (e.g., Compustar's FT-DAS-II sensor).

- Early Detection: Can detect an attempted break-in before a door or hood is even opened.

- Comprehensive Protection: Provides protection for the entire vehicle body, including windows, wheels, and the undercarriage (against jacking).

- Deterrent: The warning chirps often scare off potential thieves.

- Sensitivity Adjustment is Key: Proper installation and calibration of the shock sensor are crucial. If it's too sensitive, it will cause false alarms due to loud vehicles, thunder, or even heavy rain. If it's not sensitive enough, it might not detect a genuine threat. Professional installation is highly recommended to ensure optimal performance.

- Environmental Factors: Vibrations from heavy trucks, construction, or even strong winds can sometimes trigger poorly adjusted sensors.

- Not a Standalone Solution: While important, a shock sensor is usually part of a comprehensive alarm system that also includes door/hood/trunk sensors, and sometimes ultrasonic or tilt sensors for maximum protection.

Metal Case Diode Bridge KBPC5010

Ship or pick up from our office.

Metal Case Diode Bridge KBPC5010

The Metal Case Diode Bridge KBPC5010 is a specific type of bridge rectifier, a crucial electronic component used to convert alternating current (AC) into direct current (DC). It is widely employed in various power supply applications. Here's a breakdown of its key features and what each part of its name signifies: What is a Bridge Rectifier? A bridge rectifier is a circuit of four (or more) diodes in a specific configuration that allows for full-wave rectification. This means it efficiently converts both the positive and negative half-cycles of an AC input into a pulsating DC output. Compared to simpler half-wave rectifiers, bridge rectifiers are more efficient and provide a smoother DC output. KBPC5010 Explained- KBPC: This is typically a series designation for a family of single-phase bridge rectifiers with specific package styles.

- 50: This number indicates the maximum average forward rectified current (Io) the device can handle, which in this case is 50 Amperes (A). This high current rating makes it suitable for demanding applications.

- 10: This number typically refers to the voltage class, often indicating a maximum repetitive peak reverse voltage (VRRM) of 1000 Volts (V) (where '10' often means 10 x 100V). This high voltage rating allows it to handle substantial AC input voltages.

- Conversion: Converts single-phase AC to pulsating DC.

- Current Rating: Up to 50 Amperes (A) average forward current.

- Voltage Rating: Up to 1000 Volts (V) repetitive peak reverse voltage.

- Surge Current Capability: Often capable of handling high non-repetitive surge currents (e.g., 400A or 450A for a short duration), which is crucial for handling initial power-on transients.

- Low Forward Voltage Drop: Minimizes power loss and improves efficiency.

- High Reliability: Designed for robust performance in various environments.

- Mounting: Typically features through-hole mounting with a screw hole for chassis or heatsink mounting.

- Terminals: Often uses 0.25" (6.35 mm) Faston terminals for easy connection. Some variants (like KBPC5010W) might have wire leads.

- Operating Temperature: Wide operating junction temperature range, often from -40°C to +150°C.

- Power supplies: As a core component to rectify AC mains voltage into DC for electronic devices.

- Battery chargers: Converting AC power to DC for charging batteries.

- Motor control circuits: Providing DC power for electric motors.

- Industrial control systems: Used in various industrial applications requiring AC-to-DC conversion.

- Input rectifiers for variable frequency drives (VFDs).

Gate Opener Remote Control

Ship or pick up from our office.

Gate Opener Remote Control

(More than 100 different designs) *433 MHz *2-5 Buttons A gate opener remote control is a handheld device that allows you to wirelessly open and close an automatic gate from a distance. It's a key component of an automated gate system, offering convenience and enhanced security for residential, commercial, and industrial properties. Here's a breakdown of what it is and how it works: What it is:- Handheld device: Typically small and portable, often designed to be kept in a car, on a keychain, or mounted on a visor.

- Transmitter: It contains a small radio transmitter that sends a wireless signal.

- User interface: Usually features one or more buttons to command the gate (e.g., open, close, stop).

- Signal Transmission: When you press a button on the remote, it sends a digitally encoded radio frequency (RF) signal (typically in the 300 to 900 MHz range) through the air.

- Signal Reception: A receiver unit, connected to the gate motor, is tuned to the same frequency as the remote. It picks up this signal.

- Signal Decoding: The receiver interprets the coded information embedded in the signal to understand the desired action (e.g., open the gate).

- Motor Activation: The decoded signal is sent to the gate's control board, which then activates the gate motor.

- Gate Movement: The motor, through various mechanisms (gears, chains, arms), physically moves the gate to open or close.

- Convenience: Allows you to operate the gate without leaving your vehicle, especially useful in bad weather or at night.

- Security: Provides controlled access to your property, deterring unauthorized entry. Many modern remotes use "rolling code" technology, which changes the code with each use, making it harder for unauthorized individuals to intercept and duplicate the signal.

- Range: Typically works within a certain distance, ranging from 20-50 feet up to 100 feet or more, depending on the model and environment.

- Compatibility: Most remotes are designed to work with specific gate opener brands and models, though universal remotes exist that can be programmed to work with various systems.

- Multiple Remotes: Many gate openers can be paired with multiple remotes, allowing several authorized users to control the gate.

- Integration: Some advanced systems can be integrated with smartphone apps, keypads, or other smart home devices for even greater control and monitoring.

- Safety Features: Often used in conjunction with safety sensors (like photo eyes or pressure sensors) that detect obstructions and prevent the gate from closing on people or objects.

Infrared PIR Motion Sensor Switch

Ship or pick up from our office.

Infrared PIR Motion Sensor Switch

An Infrared PIR Motion Sensor Switch is an electronic device that detects movement by sensing changes in infrared (IR) radiation in its field of view. "PIR" stands for Passive Infrared, meaning it doesn't emit any energy itself but rather passively monitors the infrared radiation given off by objects. 🌡️ How it Works At the core of a PIR sensor is a pyroelectric sensor, which is sensitive to heat (infrared radiation). Most PIR sensors have two halves, or "slots," wired in a differential arrangement. Here's a simplified breakdown of its operation:- Idle State: When there's no movement, both halves of the sensor detect the same amount of ambient infrared radiation from the surroundings.

- Motion Detection: When a warm object, like a human or animal, moves into the sensor's field of view, it first intercepts one half of the sensor, creating a temporary difference in the infrared radiation detected by the two halves. This difference generates a voltage pulse.

- Signal Processing: The sensor's circuitry processes this voltage pulse. If the change is significant and matches the pattern of a moving heat source, the sensor triggers an output signal.

- Fresnel Lens: A key component of a PIR sensor is the Fresnel lens . This specially designed plastic lens focuses infrared radiation from different angles onto the pyroelectric sensor, effectively dividing the detection area into multiple sensitive zones. This allows the sensor to have a wider field of view and detect movement more effectively.

- Automatic Lighting Control: This is one of the most common applications. PIR sensors turn lights on when someone enters a room, hallway, or outdoor area and turn them off after a set period of no motion, saving energy.

- Security Systems: They are integral to security alarms, detecting intruders and triggering alerts or security cameras.

- Smart Home Systems: PIR sensors play a role in smart homes for automating various functions, from lighting and HVAC systems to controlling appliances based on occupancy.

- Automatic Doors: In public buildings, they detect approaching individuals to automatically open doors.

- Energy Management: By ensuring that lights, HVAC, and other devices only operate when an area is occupied, PIR sensors contribute significantly to energy savings in residential and commercial settings.

- Wildlife Tracking and Research: Researchers use them to monitor animal movements without disturbance.

Gate Opener Remote Control

Ship or pick up from our office.

Gate Opener Remote Control

– Copy Code typeGate opener remote controls use two main code types for copying: fixed code and rolling code.

Fixed code remotes are simpler and easier to clone, while rolling code remotes offer enhanced security and require more advanced techniques for copying.

Gate Opener Remote Control Fixed Code type:

- How it works: A fixed code remote transmits the same code every time it's pressed.

- Cloning: These are generally easier to clone using a universal remote duplicator.

- Security: Less secure than rolling code, as the code can be intercepted and copied.

- Example: Commonly found in older or simpler gate opener systems.