Shop

Safety Sensor S300

Ship or pick up from our office.

Safety Sensor S300

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

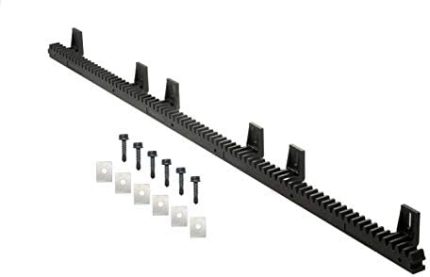

Sliding gate operator gear rack -SLGR611

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR611

*6 Holes *Length: 1018 mmSupport Roller

Ship or pick up from our office.

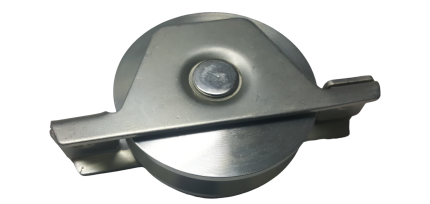

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.

Siren

Ship or pick up from our office.

Siren

A siren is a noise-making warning device designed to produce a loud, often piercing or fluctuating sound to alert people to an emergency, an approaching threat, or to draw attention to a specific situation. Sirens are characterized by their ability to generate high sound pressure levels (decibels) that can be heard over long distances and through various obstacles. There are two main types of sirens:- Mechanical (or Pneumatic) Sirens:

- How they work: These sirens produce sound by physically chopping or interrupting a flow of air. They typically consist of a rotating disk (rotor) with holes or slots, which spins rapidly past fixed holes or slots on a stationary casing (stator). As the rotor spins, it alternately allows and blocks air to pass through, creating pulsating air pressure waves that we perceive as sound. The pitch of the siren changes with the speed of the rotor and the number of holes.

- Characteristics: Often produce a characteristic "wailing" or "growling" sound. They can be very loud and consume significant power.

- Uses: Traditionally used as large outdoor warning sirens (e.g., air-raid sirens, tornado sirens) and on older emergency vehicles. You might still hear them in some older industrial settings as well.

- Electronic Sirens:

- How they work: These are the most common type found in modern applications. They generate sound electronically using circuits like oscillators, modulators, and amplifiers. These circuits synthesize various siren tones, which are then played through powerful external speakers.

- Characteristics: Highly versatile, able to produce a wide range of distinct tones (e.g., Wail, Yelp, Phaser/Piercer, Hi-Lo, Air Horn, Manual), and can often include voice announcements. They are generally more compact, consume less power than large mechanical sirens, and are easier to control.

- Uses:

- Emergency Vehicles: Police cars, ambulances, fire engines, and other emergency response vehicles use electronic sirens to alert traffic and pedestrians to their presence and urgency. Different tones are often used for different situations (e.g., Wail for distant approach, Yelp for closer proximity or heavy traffic, Air Horn for immediate attention).

- Vehicle Alarms: Car alarms commonly use a smaller, electronic siren (or the vehicle's horn) to sound a loud alert when triggered by a sensor (like a shock sensor, door sensor, or ultrasonic sensor).

- Security Systems: Residential and commercial alarm systems use sirens to deter intruders and alert occupants and neighbors to a security breach.

- Industrial and Safety Alarms: Used in factories, construction sites, and other workplaces to signal shift changes, emergencies, or specific warnings.

- Civil Defense/Public Warning Systems: Modern outdoor warning systems often use large electronic sirens that can broadcast specific tones and even pre-recorded voice messages for events like severe weather, hazardous material spills, or other public safety alerts.

UHF Licence Plate

Ship or pick up from our office.

UHF Licence Plate

A UHF (Ultra High Frequency) Licence Plate access control system is a vehicle identification and access management solution that uses UHF RFID (Radio Frequency Identification) technology to automatically grant or deny entry to vehicles. Instead of relying on traditional license plate recognition (ANPR/LPR) which uses cameras to read visible plates, UHF systems use RFID tags, often in the form of stickers or cards, affixed to vehicles. 🚗 When a vehicle with a registered UHF RFID tag approaches an access point (like a gate or barrier), a UHF reader emits radio waves. The tag, powered by these waves, transmits its unique identification data back to the reader. This data is then sent to an access control system which verifies the vehicle's authorization. If authorized, the system triggers the gate to open, allowing for fast, hands-free, and seamless entry and exit. This technology is widely used in places requiring efficient and secure vehicle flow, such as:- Gated communities 🏡

- Parking facilities (corporate, commercial, residential) 🅿️

- Industrial sites and logistics hubs 🏭

- Toll roads 🛣️

- UHF RFID Tags: These are small, passive (battery-less) or semi-active devices that contain a microchip storing a unique identification number and an antenna. They are typically affixed to the vehicle's windshield or license plate. When exposed to radio waves from a reader, the tag's antenna collects energy, powering the microchip to transmit its data.

- UHF RFID Readers: These devices are installed at access points (e.g., gate entrances) and emit radio waves to detect and read the RFID tags on approaching vehicles. They have antennas to send and receive signals, and a processor to decode the data from the tags. UHF readers typically have a longer read range (up to 10-12 meters or more) compared to other RFID frequencies, allowing vehicles to pass without fully stopping.

- Access Control System (Software/Controller): This is the "brain" of the system. The reader sends the tag's ID number to this system. The access control software then compares this ID with its database of authorized vehicles. Based on pre-defined criteria (e.g., specific times of day, authorized user groups), it determines whether to grant or deny access.

- Barrier/Gate System: If access is granted by the control system, a signal is sent to the physical barrier (like a boom gate or sliding gate), which opens to allow the vehicle to pass.

- Speed and Efficiency 🚀: Vehicles don't need to stop or roll down windows, significantly reducing traffic congestion, especially during peak hours. This provides a "frictionless" entry experience.

- Long Read Range 📏: UHF RFID allows for detection from several meters away, enabling quick processing of vehicles even at higher speeds.

- Reliability in Diverse Conditions 🌧️☀️: Unlike optical ANPR systems that can be affected by dirt, rain, snow, or poor lighting, UHF RFID tags are generally more robust and less susceptible to environmental factors.

- Enhanced Security 🔒: RFID tags are difficult to duplicate or tamper with, offering a higher level of security than some other methods. The system also logs all entries and exits, providing a clear audit trail.

- Reduced Operational Costs 💰: Automation minimizes the need for manual gate attendants, leading to lower labor costs over time. There's also no need for physical cards or key fobs that can be lost or damaged, saving on replacement costs.

- Integration Capabilities 🔗: These systems can often integrate seamlessly with other security and management platforms, such as visitor management systems, surveillance cameras, and parking management software, for a comprehensive solution.

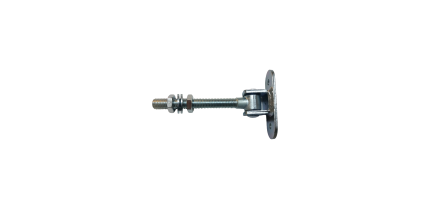

Swing gate adjustable hinge

Ship or pick up from our office.

Swing gate adjustable hinge

*Steel material *Heavy-duty hinge *5-1/2” Length (Total 7-1/2”) x 4-1/2” Width *Bolt thickness: 3⁄4”Sliding gate V-Groove wheels – SLGWSD410IB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410IB

*Heavy-duty *Steel material *Double bearing *Interior Bracket *Max 410 Kg *98 mm Diameter x 33 mm WidthA sliding gate V-groove wheel is a type of wheel designed to roll along a V-shaped track, providing support and guidance for sliding gates, particularly those made of metal.

The V-groove in the wheel precisely matches the track, ensuring smooth, stable, and quiet operation. These wheels are often used in industrial and heavy-duty applications due to their ability to handle significant weight and resist wear.

Here's a more detailed explanation:

-

V-Groove Design:The defining feature of these wheels is the V-shaped groove on their circumference. This groove fits snugly onto a corresponding V-shaped track, which can be made of angle iron or other suitable materials.

-

Track System:The track is typically installed along the path where the gate will slide, providing a stable and guided surface for the wheels to roll on.

-

Benefits:V-groove wheels offer several advantages, including:

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

- Stability: The V-groove design provides excellent stability, preventing the gate from wobbling or derailing.

- Durability: Many V-groove wheels are made from durable materials like steel or nylon, offering good wear resistance and longevity.

- Load Capacity: They can handle substantial weight, making them suitable for heavy gates.

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

-

Applications:V-groove wheels are commonly used in:

- Industrial Gates: Supporting heavy doors in factories and warehouses.

- Heavy-Duty Sliding Gates: For residential and commercial properties.

- Automated Gates: Used in conjunction with gate operators.

- Other Sliding Applications: They can also be found in other applications like sliding machinery or even pet gates.

- Industrial Gates: Supporting heavy doors in factories and warehouses.

-

Materials:V-groove wheels can be made from various materials, including:

- Steel: Offers high strength and load capacity.

- Nylon: Provides good wear resistance and reduced noise.

- Polyurethane: Offers a good balance of durability and quiet operation.

- Steel: Offers high strength and load capacity.

-

Installation:The wheels are typically mounted to the bottom of the gate, allowing them to roll along the track.

Sliding gate V-Groove wheels – SLGWSD410EB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410EB

*Steel material *Double bearing *Exterior Bracket *Max 410 Kg *98 mm Diameter x 36 mm Width *Heavy-dutyVehicle central door lock actuator

Ship or pick up from our office.

Vehicle central door lock actuator

A vehicle central door lock actuator is the electromechanical component responsible for physically locking and unlocking your car's doors when you press a button on your key fob, the interior door switch, or when the central locking system otherwise activates (e.g., speed-sensitive locking). Think of it as the "muscle" of your car's power door locks. Here's a more detailed breakdown: How it Works:- Signal Transmission: When you press the lock or unlock button on your key fob (remote control) or the switch inside the car, a radio frequency signal or an electrical signal is sent to the vehicle's Electronic Control Unit (ECU), often referred to as the Body Control Module (BCM).

- Processing by ECU: The ECU decodes this signal and determines whether the command is to lock or unlock the doors.

- Actuator Activation: The ECU then sends an electrical current to the door lock actuator located inside each door.

- Mechanical Movement: The actuator contains a small electric motor, a set of gears, and linkages (or sometimes a cable).

- When the motor receives the electrical current, it rotates in one direction to engage the locking mechanism (locking the door) or in the opposite direction to disengage it (unlocking the door).

- The gears amplify the motor's force, and the linkages convert the rotational motion of the motor into the linear or pivotal motion needed to move the door latch and lock/unlock the door.

- Feedback (Optional): Some systems provide feedback, such as a light flash or a horn chirp, to confirm that the doors have been locked or unlocked.

- Electric Motor: A small, reversible DC motor that provides the power.

- Gear Train: A series of gears that transmit and multiply the motor's torque to move the locking mechanism.

- Linkages/Cable: Connect the internal mechanism of the actuator to the door's actual latching mechanism.

- Electrical Contacts/Switches: These are inside the actuator and tell the ECU the current state of the lock (locked or unlocked).

- Housing: Encapsulates and protects all the internal components.

- Motor-driven Actuators (Most Common in Modern Cars): As described above, these use a small electric motor and gears. They offer precise control and are generally durable.

- Solenoid-driven Actuators (Older or Simpler Systems): These use an electromagnetic coil (solenoid) to create a rapid, linear pulling or pushing motion. They are typically simpler but can be less robust for frequent use.

- Convenience: Allows for simultaneous locking or unlocking of all doors with a single action, eliminating the need to manually lock each door.

- Security: Ensures all doors are properly locked, preventing unauthorized access.

- Safety: Modern systems often include features like:

- Speed-sensitive locking: Doors automatically lock when the vehicle reaches a certain speed.

- Automatic re-locking: If you unlock the car but don't open a door within a certain time, the doors will re-lock automatically.

- Anti-theft features: Some systems disable interior release levers when "double locked" to prevent entry even after glass breakage.

- Remote Keyless Entry: Integral to the operation of key fob remotes.

- Inconsistent Locking/Unlocking: One or more doors don't respond reliably to the lock/unlock command from the fob or interior switch.

- Unusual Noises: Clicking, grinding, buzzing, or whirring sounds coming from inside the door when trying to lock or unlock. This often indicates worn gears or a struggling motor.

- Sluggish Operation: The door lock moves slowly or with a delay.

- Door Stays Locked or Unlocked: A specific door might be stuck in the locked or unlocked position, even when the rest of the car responds. You might still be able to operate it manually.

- Random Locking/Unlocking: The door might lock or unlock itself without input.

- "Door Ajar" Warning Light: In some cases, a faulty actuator (specifically, a worn internal switch) can cause the "door open" warning light to stay on even when the door is closed, or trigger the car alarm.