Shop

Sliding gate opener – Royalgate RGSL2TO

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL2TO

*Suitable gate weight: Maximum 2000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release keyDoor Strike Lock

Ship or pick up from our office.

Door Strike Lock

*Fail-Secure/Fail-Safe *Capacity: 100 Kg *DC 12 VAn electric strike is an electromechanical lock release device that replaces a standard door strike plate.

It allows a door to be opened remotely, typically via an access control system, without manually retracting the latch. When activated, the electric strike releases the latch, enabling the door to be opened.

Here's a more detailed explanation:

Functionality:

-

Replaces Standard Strike:Electric strikes are installed in the door frame, taking the place of the standard strike plate.

-

Remote Release:They are designed to work with various access control systems, such as keypads, card readers, or intercoms.

-

Activation:When an authorized signal is received (e.g., a code is entered, a card is swiped), the electric strike releases the latch, allowing the door to be opened.

-

Fail-Safe or Fail-Secure:Electric strikes can be configured in either a fail-safe or fail-secure mode.

- Fail-safe: In this mode, the door unlocks when power is lost, making it suitable for safety applications where access is needed during power outages.

- Fail-secure: In this mode, the door remains locked when power is lost, requiring power to unlock, making it suitable for high-security applications.

How it Works:

- The electric strike contains a solenoid, which is an electromagnet.

- When the solenoid is activated by an electrical signal, it moves a component (like an armature) that allows the latch to move freely.

- This movement releases the door, allowing it to be opened.

Key Differences from Other Locks:

-

Electric vs. Magnetic Locks:Unlike magnetic locks, which use powerful magnets to hold the door closed, electric strikes release the latch mechanism.

-

Remote Access:Electric strikes offer remote access control, allowing doors to be unlocked without manual intervention.

-

Versatility:They can be used with various locking mechanisms, including cylindrical, mortise, and rim exit devices.

Common Applications:

-

Access Control:Electric strikes are a core component of access control systems in commercial and residential settings.

-

Security:They provide a higher level of security compared to standard locks, especially when used with fail-secure configurations.

-

Safety:In fail-safe configurations, they ensure safe egress during emergencies.

-

Specific Areas:They are commonly found in reception areas, daycare centers, and other locations where controlled access is needed.

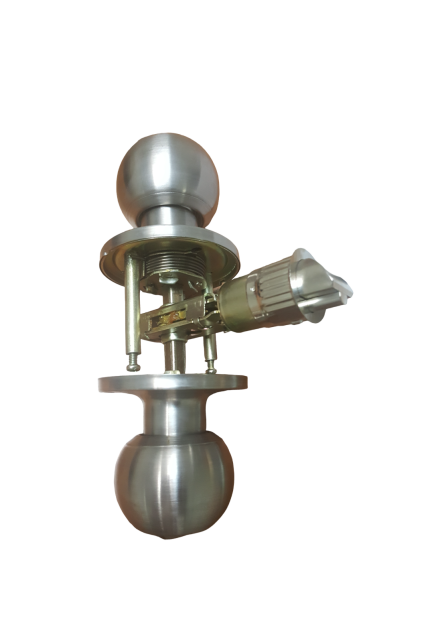

Pedestrian gate manual lock (Two-sided key)

Ship or pick up from our office.

Pedestrian gate manual lock (Two-sided key)

A "pedestrian gate manual lock (two-sided key)" refers to a type of gate latch or lock that can be operated and secured with a key from both sides of the gate. Here's a breakdown of what that means and why it's useful:- Manual Lock: This indicates that the lock is operated by hand, typically by turning a key or a knob/lever, rather than being electric or automated.

- Two-Sided Key (or Keyed on Both Sides): This is the key feature. It means that there is a key cylinder on both the exterior and interior sides of the gate. This allows you to:

- Lock the gate from either the inside or the outside using a key.

- Unlock the gate from either the inside or the outside using a key.

- Convenience: You don't have to walk around the gate to unlock it if you're on the "wrong" side.

- Security: It provides a consistent level of security from both directions, preventing unauthorized access whether someone is trying to get in from the outside or out from the inside (if that's a concern).

- Accessibility: It can be crucial for pedestrian gates that serve as primary entry points, offering easy access for residents or authorized personnel from either side.

- Deadbolt Hook Locks: These use a hook-shaped bolt that engages with a strike plate on the gate post.

- Mortise Locks: These are installed within a pocket cut into the gate frame, offering a clean, flush appearance and good security.

- Rim Locks: These are surface-mounted on the gate, making them easier to install.

- Latches with an external access kit: Some general-purpose gate latches can be converted to be two-sided key-lockable with an additional kit.

Pedestrian gate electric lock with remote control

Ship or pick up from our office.

Pedestrian gate electric lock with remote control

* Two remote controls included *DC 12 V pedestrian gate electric lock with a remote control is a security system that allows you to lock and unlock a walk-through gate using an electrical mechanism, typically activated by a remote control. This provides convenience and enhanced security, as you don't need a physical key to open the gate. Here's a breakdown of what it entails: How it Works:- Electric Lock Mechanism: Instead of a traditional manual deadbolt or latch, an electric lock uses an electrical impulse to control a bolt or latch. This impulse can come from a control board connected to various access control devices.

- Remote Control Activation: A key component is the remote control, which sends a wireless signal (radio frequency) to a receiver connected to the lock's control system. When the signal is received and recognized, the lock is instructed to engage (lock) or disengage (unlock).

- Integration with Gate Systems: These locks are often integrated with automatic gate openers or access control systems. When the gate closes, the lock can automatically engage, and when a remote signal is given, it disengages to allow the gate to open.

- Power Source: Electric locks require a power source, typically low voltage (e.g., 12V DC). Many systems include a battery backup to ensure continued operation during power outages.

- Solenoid Locks: These use an electromagnet to extend or retract a bolt, securing or releasing the gate.

- Electromagnetic Locks (Mag Locks): These consist of an electromagnet mounted on the gate frame and a metal strike plate on the gate itself. When power is applied, the electromagnet creates a powerful magnetic force that holds the gate shut. Removing power releases the lock.

- Electric Strikes: These replace the standard strike plate on the gate frame. They contain a solenoid that, when activated, pivots or retracts to release the gate's latch. They are often combined with a traditional keyed doorknob or lever.

- Remote Operation: The primary benefit, allowing you to open or close the gate from a distance.

- Automatic Operation: Many models automatically lock when the gate closes, improving security.

- Fail-Safe vs. Fail-Secure:

- Fail-Secure: The lock remains locked when power is lost. This is common for high-security applications where you want the gate to stay secure even during a power outage.

- Fail-Safe: The lock unlocks when power is lost. This might be preferred for safety reasons, ensuring an exit path in an emergency.

- Holding Force: This indicates the strength of the lock in resisting forced entry, measured in pounds (lbs).

- Compatibility: Ensure the electric lock is compatible with your specific gate type (wood, metal, swing, etc.) and any existing or planned access control systems (keypads, intercoms, smart home systems).

- Manual Override: Many electric locks include a manual release key or mechanism for use in case of power failure or remote control malfunction.

- Durability and Weather Resistance: Given that they are outdoors, look for locks built with durable, weather-resistant materials.

- Integration with Other Access Control: Beyond remote controls, these locks can often be integrated with:

- Keypads (for code entry)

- Intercom systems (audio/video communication and remote release)

- Smartphone apps (for remote monitoring and control)

- Biometric readers (fingerprint, face scan)

Magnetic lock

Ship or pick up from our office.

Magnetic lock

*Capacity: 180 Kg *DC 12 V A magnetic lock, also known as an electromagnetic lock or maglock, is a locking device that uses the principles of electromagnetism to secure a door. Unlike traditional mechanical locks, it has no moving parts. How It Works A magnetic lock consists of two main components:- Electromagnet: This is typically mounted on the door frame. It contains a coil of wire wrapped around a ferromagnetic core.

- Armature Plate: This is a steel plate mounted on the door itself, designed to align with the electromagnet.

- High Security: Magnetic locks can provide a very strong holding force, making them difficult to force open. They are also virtually unpickable, as there are no keyholes or cylinders.

- Durability and Low Maintenance: With no moving parts, magnetic locks experience less wear and tear than traditional locks, leading to greater longevity and reduced maintenance needs.

- Quick Operation: They unlock instantly when power is cut, allowing for quick release, which is beneficial in high-traffic areas or emergencies.

- Remote Operation and Access Control Integration: Magnetic locks can be easily integrated into electronic access control systems, allowing for remote operation, key card/fob access, biometric scanning, and detailed access logging.

- Versatility: They can be installed on various door types, including glass, wood, and metal, and are suitable for both swinging and sliding doors.

- Ease of Installation: Compared to some other electric locks, maglocks can be relatively straightforward to install.

- Constant Power Requirement: Magnetic locks need a continuous power supply to remain locked. This means they are dependent on electricity, and a power outage will result in the door unlocking (fail-safe).

- Cost: While the initial cost of the lock itself might be comparable, the overall installation can be more expensive due to the need for electrical wiring, power supplies, and integration with other security systems.

- Additional Hardware for Safety: To comply with building codes and ensure safe egress, magnetic locks often require additional hardware such as push-to-exit buttons, motion sensors, or panic bars.

- Maintenance of Backup Systems: If battery backups are used to mitigate power outages, these batteries require regular checking and replacement.

Telescopic sliding gate hardware

Ship or pick up from our office.

Telescopic sliding gate hardware

Telescopic sliding gate hardware refers to the specialized components and kits used to construct and operate a telescopic sliding gate system. Unlike a traditional single-leaf sliding gate, a telescopic gate consists of multiple gate leaves (typically two or three) that slide and overlap each other as they open, significantly reducing the amount of "run-off" space required for the gate to retract. This makes them ideal for properties with limited lateral space. Here's a breakdown of the key hardware components and how they work: How a Telescopic Sliding Gate Works: The core principle behind a telescopic gate is the synchronized movement of its multiple leaves. This is typically achieved through a cable and pulley system or a geared track system.- Cable and Pulley System: This is a common method. When the primary gate leaf (the one directly driven by a motor or moved manually) begins to open, a series of cables and pulleys pull the secondary and tertiary leaves along parallel tracks. The cables are strategically routed so that each subsequent leaf moves at a faster rate, allowing them to stack neatly behind the primary leaf when fully open.

- Geared Track System: Some advanced systems use a geared track where a pinion on one gate leaf engages with a rack on the next, driving it along.

- Gate Leaves: These are the individual sections of the gate. They are designed to slide smoothly past each other.

- Tracks:

- Ground Tracks: Parallel tracks are installed on the ground for each gate leaf to slide on.

- Upper Guide Profile/Track: A top guide system is crucial for stability and smooth movement, preventing the gate leaves from wobbling or derailing.

- Wheels: Each gate leaf has wheels (often V-groove or round groove) that run along the ground tracks. These are typically heavy-duty to support the weight of the gate.

- Pulley System/Transmission Unit: This is the heart of the telescopic mechanism. It includes:

- Pulleys: Used to route and guide the steel cables.

- Steel Cables: Connect the gate leaves, ensuring synchronized movement.

- Cable Covers/Casings: Protect the cables and provide a neat appearance.

- Adjustable Pulley Systems/Tensioners: Allow for precise adjustment of cable tension to ensure smooth operation and prevent stretching over time.

- Connection Brackets/Couplers: Connect the cables to the gate leaves.

- Guide Brackets/Rollers: These are installed at the top of the gate or on a support post to keep the gate leaves aligned and stable as they move. They often feature nylon rollers to reduce friction and noise.

- Gate Stops and Receivers: To define the fully open and closed positions and secure the gate when closed.

- Gear Rack (for automated gates): If the gate is automated, a gear rack will be installed on the primary gate leaf, which engages with a pinion on the gate motor.

- Gate Motor (for automated systems): A powerful sliding gate motor is required, often a low-voltage DC motor with advanced electronics to handle the varying speeds and loads of the multiple leaves. A speed reduction gearbox may also be incorporated for safety.

- Space-Saving: The primary advantage, as they require significantly less run-off space than single-leaf sliding gates.

- Wider Opening: Allows for a wider clear opening in situations where space limitations would otherwise restrict it.

- Faster Operation: Can often open and close more quickly than a single, very large sliding gate.

- Aesthetics: Can be a more visually appealing solution for properties with limited space.

- Complexity: More complex to design and install than a standard sliding gate due to the synchronized movement.

- Maintenance: Requires regular lubrication and checking of the cable and pulley system to ensure smooth and reliable operation.

- Weight Distribution: Proper engineering is crucial to distribute the weight of multiple gate leaves evenly and ensure stability.

Keypad – K180SC103

Ship or pick up from our office.

Keypad - K180SC103

*EM/ID card/tag reader *Shock resistance *Anti-vandal Metal shell *Backlight *1000 Users *DC 12 V *IP 67 *Doorbell *Rain Shield Cover included The Keypad - K180SC103 is an access control keypad typically used for security systems, gate openers, or door entry systems. 🔑 It's designed to allow access by entering a digital code. Here's what we know about it: Functionality:- Code-Based Access: The primary function is to grant access when a correct digital code is entered.

- Security System Integration: It's likely part of a larger access control system, where it sends signals to a control panel or hub to manage entry.

- Applications: Commonly found in residential or commercial settings for controlling gates, garage doors, and electronic door locks.

- Relay Output: It features a relay output with a maximum contact of 15A/120VAC & 10A/30VDC, offering two modes: toggle click and self-hold. This allows it to control various devices, including lights, automatic feeders, and water pumps.

- Weatherproof (IP44): This rating suggests it can withstand certain outdoor conditions, making it suitable for gate or outdoor door applications.

- Timer Function: In self-hold mode, you can set a timer to adjust the working time of the connected device.

- Dimensions: Approximately 24 × 18 × 12 cm.

- Weight: Around 0.8 kg.

Sliding gate opener – Royalgate RGSL1TN

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL1TN

*Suitable gate weight: Maximum 1000 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release key Reliability and safety are at the base of the mechanical components: produced with sturdy materials, they turn on large ball bearings that are attached to die-cast aluminum housings. The endless screw is made of rolled steel and the internal gear has involute teeth. This special construction increases significantly the gear's life by decreasing its friction. The result: quiet movement, high performance, and no wear. This product is the kit solution for sliding gate installation with double sliding. Two operators, one with a control unit for perfect synchronization of the motors and accessories.Safety sensor VEDO180

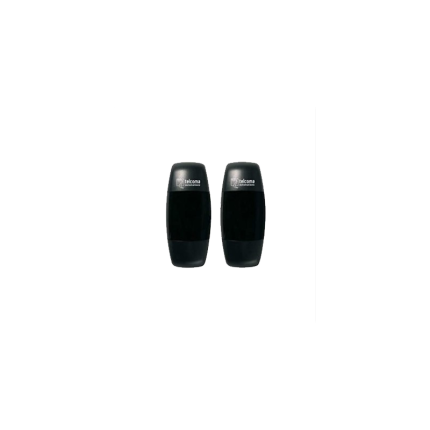

Ship or pick up from our office.

Safety sensor VEDO180

*NO/NC *AC/DC 12-24 V *Receiving Range: 25 Meters *IP 44Sliding gate opener -Royalgate RGSL1.3T

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL1.3T

*Suitable gate weight: Maximum 1300 Kg Included: *1 x Electromechanical motor *1 x Main control board *4 Meters x SLGR41 Gear rack *2 x Remote control *2 x Manual release key Open gates weighing up to 1850 lbs effortlessly with this gear rack-driven sliding gate opener. It is designed with a 110V AC motor which provides exceptional torque and its continuous operation makes it ideal for most applications. 13 ft nylon gear rack track is included in the kit and if your gates are more than 13 ft in length then you can opt for an extra rack.- Opens gates weighing up to 1850 lb

- Easy to install

- Get the desired torque and tension by adjusting the potentiometer

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close (0, 30, 60, 90 seconds)

- Reliable electromagnetism limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated

Sliding gate V-Groove wheels – SLGWSD410EB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410EB

*Steel material *Double bearing *Exterior Bracket *Max 410 Kg *98 mm Diameter x 36 mm Width *Heavy-dutySliding gate operator gear rack -SLGR612

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR612

*6 Holes *Length: 1018 mm The Sliding Gate Operator Gear Rack -SLGR612 is a specific type of gear rack designed to work with automatic sliding gate operators. ⚙️ It's an essential component that allows the gate motor to move the gate open and closed. Here's a breakdown of what that means: What is a Gear Rack for a Sliding Gate Operator? A gear rack is a linear component with teeth cut along its length. It acts like a long, straight gear. In the context of a sliding gate, the gear rack is attached to the bottom or side of the gate. The gate operator, which contains a motorized gear (or pinion), engages with these teeth. As the motor turns the pinion, it "walks" along the gear rack, causing the gate to slide horizontally. Key Features and Specifications of SLGR612 The sliding gate operator gear rack -SLGR612 described as a "Special Type" of gear rack, with the following known characteristics:- Length: 1018 mm (approximately 3.34 feet) 📏

- Holes: It features 6 holes, likely for mounting to the gate.

- Weight: 10 kg

- Dimensions: 200 × 100 × 100 cm (these dimensions seem to refer to the packaging or a larger kit, not just the rack itself, which is a common occurrence in product listings).

- Material: While not explicitly stated for SLGR612, gear racks are commonly made from galvanized steel for heavy-duty applications or nylon reinforced with a steel core for quieter operation and lighter gates. Heavy gates typically use steel racks.

- Smooth and Reliable Operation: The precise engagement between the pinion and the rack teeth ensures consistent and smooth movement of the gate.

- Durability: Made from robust materials, they withstand daily use and varying weather conditions.

- Enhanced Security: The mechanical linkage makes it difficult to force the gate open manually without the operator's input.

- Convenience: They enable the automated opening and closing of gates via remote controls, keypads, or other access control systems.