Shop

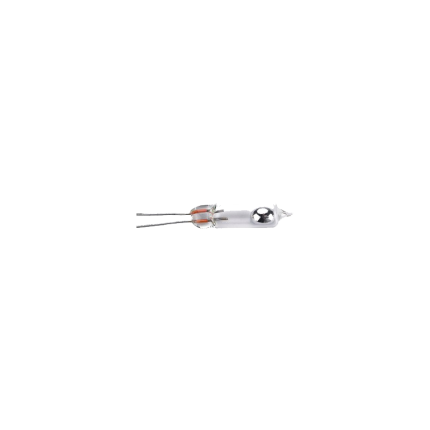

Mercury Level Switch

Ship or pick up from our office.

Mercury Level Switch

A mercury level switch is a type of electrical switch that uses a small amount of liquid mercury to open or close an electrical circuit based on its position or the level of a liquid. Essentially, the mercury acts as a conductive bridge between electrical contacts. How it Works The core component of a mercury level switch is a sealed glass or metal capsule containing one or more electrical contacts and a small, free-moving drop of mercury. When the switch or the liquid it's monitoring changes its tilt or level:- Tilt Switches: Gravity pulls the mercury to the lowest point within the capsule. If the tilt is sufficient, the mercury will flow to connect two or more contacts, completing an electrical circuit. Tilting it in the opposite direction moves the mercury away, breaking the circuit.

- Float Switches: In liquid level applications, the mercury switch is often integrated with a float mechanism. As the liquid level rises or falls, the float moves, which in turn tilts the mercury switch, causing the mercury to connect or disconnect the contacts.

- Displacement Switches: Some designs use a "plunger" that dips into a pool of mercury, raising the mercury level to contact an electrode and complete the circuit.

- Thermostats: In older thermostats, they controlled heating and cooling systems.

- Sump Pumps: Used to automatically turn on the pump when water levels rise.

- Appliances: Found in washing machines (for lid switches and load balancing), chest freezers (for lid lights), and some gas appliances like ovens and water heaters (as flame sensors).

- Automotive Industry: Previously used for trunk lid lights, ride control, and anti-lock braking systems.

- Industrial Settings: Utilized in liquid level control and safety systems.

- Roll Sensing/Tip-over Warnings: For construction equipment or other vehicles operating on uneven terrain.

- Durability and Reliability: The sealed contacts prevent oxidation, leading to a long lifespan.

- Quiet Operation: No abrupt snapping of contacts.

- No Contact Erosion: Mercury's liquid nature prevents the wear and tear seen in mechanical contacts.

- Spark-Free: They don't produce sparks when making or breaking circuits, making them suitable for hazardous environments.

- Toxicity of Mercury: This is the primary and most significant disadvantage. Mercury is a highly toxic substance, posing serious environmental and health risks if released.

- Environmental Concerns: Improper disposal of mercury switches can lead to widespread contamination. Due to these concerns, the use of mercury switches has been largely phased out in many applications, especially in new products.

- Sensitivity to Gravity/Orientation: While an advantage for tilt sensing, it makes them unsuitable for portable or mobile devices where orientation changes or vibrations could cause false readings.

- Limited Functionality: Most mercury switches provide only a simple on/off function.

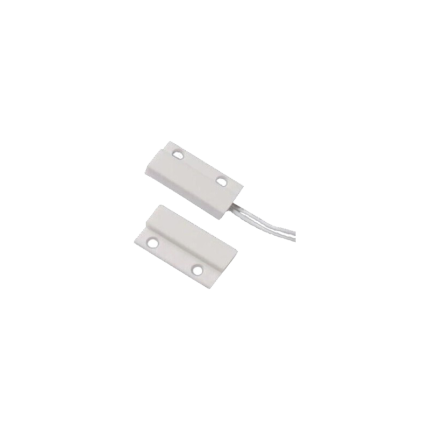

Magnetic Contact Switch – Wired

Ship or pick up from our office.

Magnetic Contact Switch

A magnetic contact switch, often simply called a magnetic contact or door/window sensor, is a simple yet highly effective security device that detects when a door, window, gate, or any movable barrier is opened or closed. How it Works: It consists of two main parts:- The Sensor Unit (with a Reed Switch): This part contains a reed switch. A reed switch is a small, hermetically sealed (airtight) glass capsule with two tiny, flexible magnetic metal reeds (or contacts) inside. These reeds are usually made of a ferromagnetic material. This sensor unit is typically mounted on the stationary part of the opening (e.g., the door frame, window frame, or gate post).

- The Magnet Unit: This part contains a small, permanent magnet. This unit is mounted on the moving part of the opening (e.g., the door itself, the window sash, or the gate panel).

- Closed Position (Circuit Complete): When the door/window/gate is closed, the magnet unit is in very close proximity to the sensor unit. The magnetic field from the permanent magnet pulls the two tiny reeds inside the glass capsule together, causing them to make electrical contact. This completes an electrical circuit, indicating that the opening is secured.

- Many common contacts are "Normally Open" (NO), meaning the circuit is open when the magnet is away and closes when the magnet is near.

- Some are "Normally Closed" (NC), meaning the circuit is closed when the magnet is near and opens when the magnet is away. This is very common in security systems, as an "open" circuit triggers an alarm.

- Opened Position (Circuit Broken/Changed): When the door/window/gate is opened, the magnet moves away from the reed switch. As the magnetic field weakens, the reeds spring back to their original position, breaking the electrical contact. This change in the circuit (from closed to open, or open to closed, depending on the type) signals the connected system (e.g., a car alarm, home security system, or gate control panel) that the opening has occurred.

- Security Systems (Homes, Businesses, Vehicles): This is the most prevalent use. Magnetic contacts are placed on:

- Doors and Windows: To detect unauthorized entry. When a door or window is opened, it triggers the alarm.

- Garage Doors/Overhead Doors: Larger, more robust magnetic contacts are used for garage doors.

- Gates: Used on pedestrian gates or even main driveway gates (sometimes in conjunction with the gate opener's own limit switches) to monitor their open/closed status for security purposes.

- Safes and Vaults: To detect if they have been opened.

- Vehicle Doors/Trunks/Hoods: While vehicles have internal sensors, magnetic contacts can be added for enhanced security on specific compartments or custom modifications.

- Access Control Systems: To monitor entry and exit points, log access events, or control other devices based on door status.

- Automation Systems: To trigger actions based on the status of a movable part. Examples include:

- Turning lights on/off when a door opens.

- Indicating when a cabinet door is ajar.

- Position sensing in industrial machinery.

- Appliance Safety: Some appliances use magnetic contacts to ensure a lid is closed or a guard is in place before operation.

- Surface Mount: Most common, easily screwed or adhered to the surface of the frame and door.

- Recessed/Flush Mount: Designed to be drilled into the frame and door for a more discreet, hidden installation.

- Heavy Duty/Overhead Door Contacts: Larger and more rugged, built for the heavier use and larger gaps often found with garage or industrial doors.

- Wired vs. Wireless:

- Wired: Physically connected to the alarm panel via wires, offering high reliability.

- Wireless: Contain a small battery and a radio transmitter to send signals wirelessly to the alarm panel, offering easier installation.

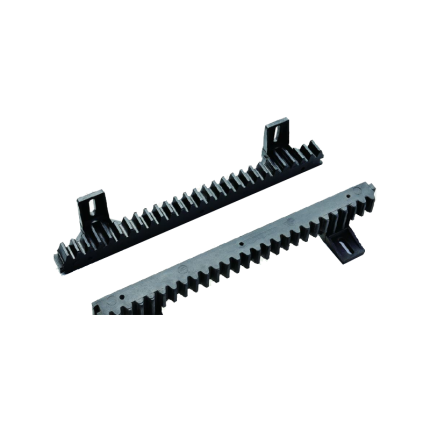

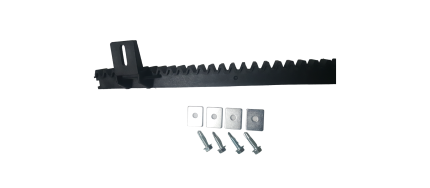

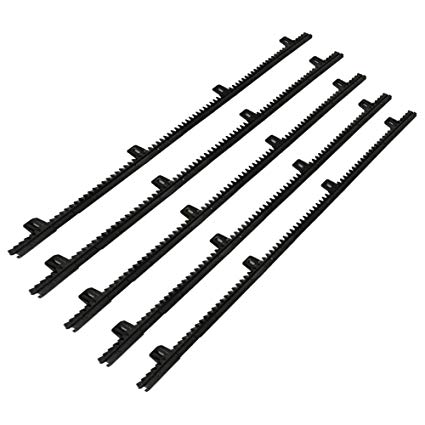

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

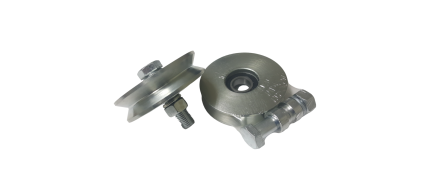

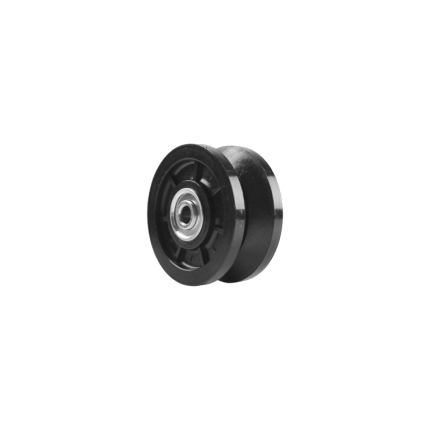

Sliding gate V-Groove nylon wheels -SLGWNS250

Ship or pick up from our office.

*Double bearing *Max 250 Kg *98 mm Diameter (4") x 44 mm Width (1-3/4") (Heavy-duty bolts, nuts, and washers are included)Diode Bridge GBU808

Ship or pick up from our office.

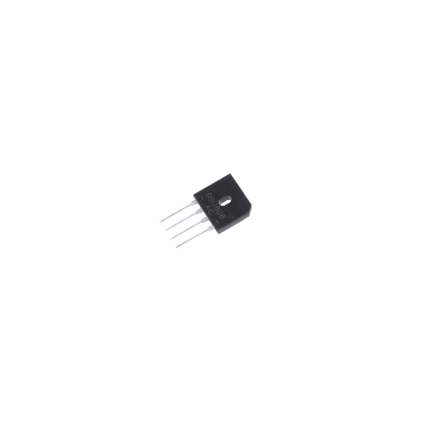

Diode Bridge GBU808

*8A *800V *Single Phase *Rectifier IC ChipPedestrian Gate Hinges

Ship or pick up from our office.

Pedestrian Gate Hinges

Pedestrian gate hinges are designed to allow a gate intended for pedestrian use to swing open and closed, connecting the gate to its post or frame.

These hinges are crucial for the smooth operation and secure closure of the gate, ensuring proper alignment and functionality. They can be surface-mounted, bolt-on, or weld-on, and may include features like spring-assist or adjustable tension for self-closing.

Here's a more detailed breakdown:

-

Function:Pedestrian gate hinges primarily serve to join the gate to its supporting structure (post or frame) and allow for rotation.

-

Types:They can be surface-mounted, bolt-on, or weld-on, offering different installation methods.

-

Features:Some hinges incorporate self-closing mechanisms, like spring-assist or adjustable tension, which can be important for safety or convenience.

-

Materials:They are commonly made from steel, stainless steel, or polymer, ensuring durability and resistance to the elements.

-

Applications:Pedestrian gate hinges are suitable for various settings, including residential, HOA, and commercial properties, especially for side gates, walkways, and restricted access enclosures.

-

Considerations:When choosing hinges, factors like the gate's weight, size, and desired functionality (e.g., self-closing) should be taken into account.

Sliding gate V-Groove wheels – SLGWSS400

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSS400

*Heavy-duty *Steel material *Single bearing *Max 400 Kg *98 mm Diameter x 32 mm Width *Heavy-duty bolts, nuts, and washers are includedSliding gate V-groove wheels are designed to roll along a V-shaped track, providing a guided and stable rolling surface for sliding gates.

These wheels are crucial for the smooth operation of sliding gates, especially those made of metal or used in industrial settings. The V-groove design minimizes friction, reduces noise and vibration, and ensures the gate remains aligned with its track.

Here's a more detailed explanation:

-

Function:V-groove wheels are specifically designed to roll along a V-shaped track, which can be made of angle iron or other suitable materials. This design provides guidance and support for the gate, preventing it from deviating from its intended path.

-

Benefits:The V-groove design offers several advantages:

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

- Noise Reduction: The smooth rolling action reduces noise and vibration compared to other wheel designs.

- Stability: The V-groove ensures the gate remains aligned with the track, preventing it from wobbling or derailing.

- Load Capacity: V-groove wheels are often designed with heavy-duty construction to handle substantial weight, making them suitable for various gate sizes and materials.

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

-

Materials:V-groove wheels are available in different materials, including:

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

- Steel: Provides strength and durability, suitable for heavy-duty applications.

- Cast Iron: Another durable option, often used for industrial applications.

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

-

Applications:V-groove wheels are used in a wide range of sliding gate applications, including:

- Residential Gates: For driveways and other entryways.

- Commercial Gates: In businesses and industrial settings.

- Industrial Doors: In factories and warehouses.

- Residential Gates: For driveways and other entryways.