Shop

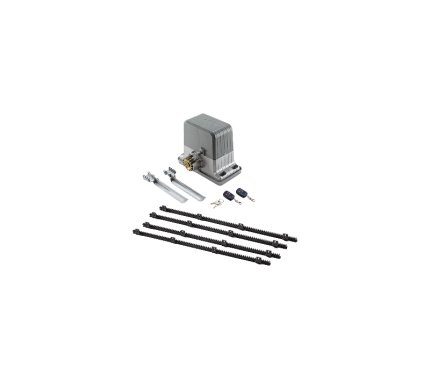

Sliding gate opener – Royalgate RGSL2TO

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL2TO

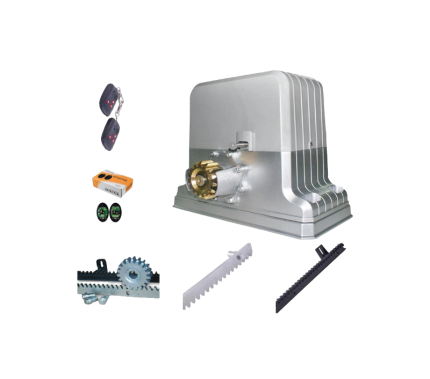

Sliding gate opener -Royalgate RGSL1.8TO

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL1.8TO

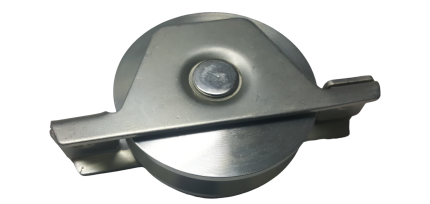

Sliding gate V-Groove wheels – SLGWSD410IB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410IB

*Heavy-duty *Steel material *Double bearing *Interior Bracket *Max 410 Kg *98 mm Diameter x 33 mm WidthA sliding gate V-groove wheel is a type of wheel designed to roll along a V-shaped track, providing support and guidance for sliding gates, particularly those made of metal.

The V-groove in the wheel precisely matches the track, ensuring smooth, stable, and quiet operation. These wheels are often used in industrial and heavy-duty applications due to their ability to handle significant weight and resist wear.

Here's a more detailed explanation:

-

V-Groove Design:The defining feature of these wheels is the V-shaped groove on their circumference. This groove fits snugly onto a corresponding V-shaped track, which can be made of angle iron or other suitable materials.

-

Track System:The track is typically installed along the path where the gate will slide, providing a stable and guided surface for the wheels to roll on.

-

Benefits:V-groove wheels offer several advantages, including:

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

- Stability: The V-groove design provides excellent stability, preventing the gate from wobbling or derailing.

- Durability: Many V-groove wheels are made from durable materials like steel or nylon, offering good wear resistance and longevity.

- Load Capacity: They can handle substantial weight, making them suitable for heavy gates.

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

-

Applications:V-groove wheels are commonly used in:

- Industrial Gates: Supporting heavy doors in factories and warehouses.

- Heavy-Duty Sliding Gates: For residential and commercial properties.

- Automated Gates: Used in conjunction with gate operators.

- Other Sliding Applications: They can also be found in other applications like sliding machinery or even pet gates.

- Industrial Gates: Supporting heavy doors in factories and warehouses.

-

Materials:V-groove wheels can be made from various materials, including:

- Steel: Offers high strength and load capacity.

- Nylon: Provides good wear resistance and reduced noise.

- Polyurethane: Offers a good balance of durability and quiet operation.

- Steel: Offers high strength and load capacity.

-

Installation:The wheels are typically mounted to the bottom of the gate, allowing them to roll along the track.

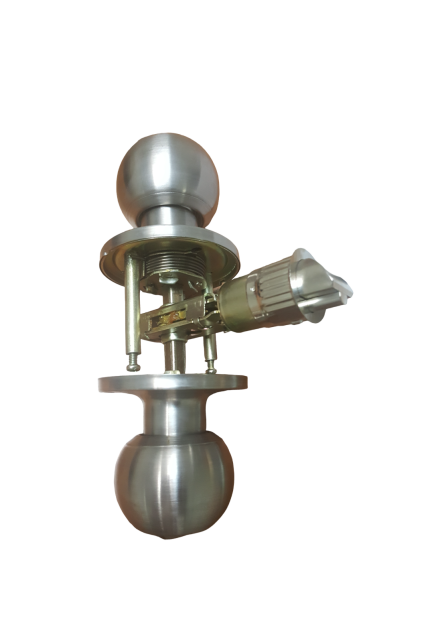

Door Strike Lock

Ship or pick up from our office.

Door Strike Lock

An electric strike is an electromechanical lock release device that replaces a standard door strike plate.

It allows a door to be opened remotely, typically via an access control system, without manually retracting the latch. When activated, the electric strike releases the latch, enabling the door to be opened.

Here's a more detailed explanation:

Functionality:

-

Replaces Standard Strike:Electric strikes are installed in the door frame, taking the place of the standard strike plate.

-

Remote Release:They are designed to work with various access control systems, such as keypads, card readers, or intercoms.

-

Activation:When an authorized signal is received (e.g., a code is entered, a card is swiped), the electric strike releases the latch, allowing the door to be opened.

-

Fail-Safe or Fail-Secure:Electric strikes can be configured in either a fail-safe or fail-secure mode.

- Fail-safe: In this mode, the door unlocks when power is lost, making it suitable for safety applications where access is needed during power outages.

- Fail-secure: In this mode, the door remains locked when power is lost, requiring power to unlock, making it suitable for high-security applications.

- Fail-safe: In this mode, the door unlocks when power is lost, making it suitable for safety applications where access is needed during power outages.

How it Works:

- The electric strike contains a solenoid, which is an electromagnet.

- When the solenoid is activated by an electrical signal, it moves a component (like an armature) that allows the latch to move freely.

- This movement releases the door, allowing it to be opened.

Key Differences from Other Locks:

-

Electric vs. Magnetic Locks:Unlike magnetic locks, which use powerful magnets to hold the door closed, electric strikes release the latch mechanism.

-

Remote Access:Electric strikes offer remote access control, allowing doors to be unlocked without manual intervention.

-

Versatility:They can be used with various locking mechanisms, including cylindrical, mortise, and rim exit devices.

Common Applications:

-

Access Control:Electric strikes are a core component of access control systems in commercial and residential settings.

-

Security:They provide a higher level of security compared to standard locks, especially when used with fail-secure configurations.

-

Safety:In fail-safe configurations, they ensure safe egress during emergencies.

-

Specific Areas:They are commonly found in reception areas, daycare centers, and other locations where controlled access is needed.

Pedestrian gate manual lock (Two-sided key)

Ship or pick up from our office.

Pedestrian gate manual lock (Two-sided key)

Pedestrian gate electric lock with 2 Remote controls

Ship or pick up from our office.

Pedestrian gate electric lock with 2 Remote controls

*DC 12 VMagnetic lock

Ship or pick up from our office.

Magnetic lock

*Capacity: 180 Kg *DC 12 VTelescopic sliding gate hardware

Ship or pick up from our office.

Telescopic sliding gate hardware

Support Roller

Ship or pick up from our office.

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.