Shop

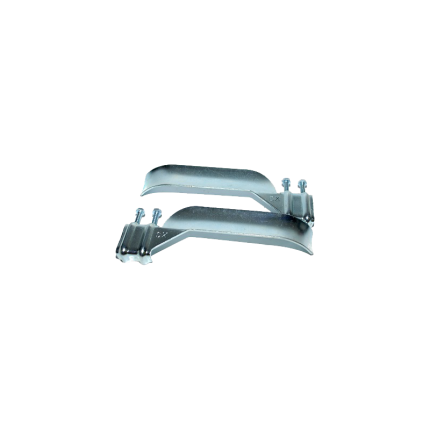

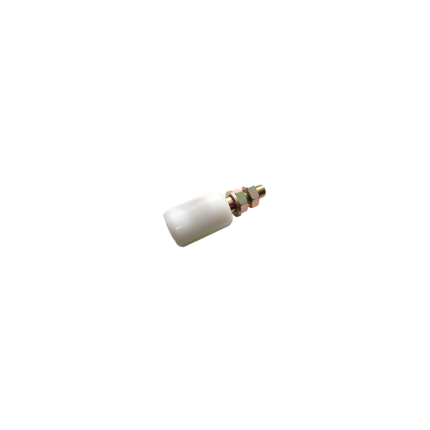

Sliding gate operator limit stopper bracket

Ship or pick up from our office.

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment.A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions.

These brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track.

Here's a more detailed explanation:

-

Purpose:The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling.

-

How it works:The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor.

-

Components:

- Bracket: The physical structure that holds the sensor.

- Sensor: A device (often a magnet) that interacts with the limit switch.

- Limit Switch: A switch on the gate operator's control board that is activated by the sensor.

- Bracket: The physical structure that holds the sensor.

-

Importance:

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

- Reliability: Ensures consistent and reliable gate operation by defining the travel limits.

- Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

Sliding gate operator limit stopper bracket

Ship or pick up from our office.

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment. A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions. These limit stopper brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track. Here's a more detailed explanation: Purpose: The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling. How it works: The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor. Components: Bracket: The physical structure that holds the sensor. Sensor: A device (often a magnet) that interacts with the limit switch. Limit Switch: A switch on the gate operator's control board that is activated by the sensor. Importance: Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury. Reliability: Ensures consistent and reliable gate operation by defining the travel limits. Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.Sliding gate operator main control board – Difermatic

Ship or pick up from our office.

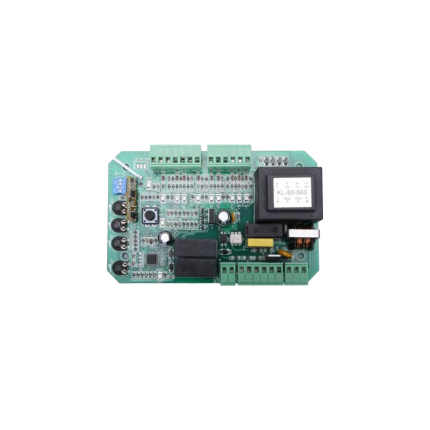

Sliding gate operator main control board – Difermatic

The main control board for a Difermatic sliding gate operator, such as the DSL600, acts as the "brain" of the system, managing all the gate's functions.

It receives commands from remote controls or other inputs, and then controls the motor to open and close the gate. It also manages safety features like obstacle detection and may allow for adjustments to speed, force, and other parameters.

Key Functions:

- Receives and Processes Commands: The control board receives signals from remote controls, keypads, or safety sensors.

- Controls the Motor: It sends instructions to the gate's motor to open or close the gate based on the received commands.

- Manages Safety Features: Many control boards include safety features like obstacle detection (which can reverse the gate's direction if it encounters an obstruction) and slow-down functions.

- Adjustable Settings: Some models allow for adjustment of speed, force, and other parameters.

- Power Supply: The control board typically operates on a 24V power supply.

Specific to Difermatic:

- The Difermatic DSL600 is a 600kg sliding gate opener, indicating the weight capacity of the gate it's designed to handle.

- Difermatic products are known for their Italian design and quality.

- The control board likely has features like remote control operation, safety mechanisms, and adjustable speed and force settings.

Additional Notes:

- Many sliding gate control boards, including those from Difermatic, are designed for easy installation and user-friendly operation.

- They often include a built-in receiver for remote controls and may be compatible with other accessories like photocells and alarm lamps.

- Some control boards also feature automatic closing functions and can be programmed for various delay times.

Sliding gate operator main control board – Key Automation

Ship or pick up from our office.

Sliding gate operator main control board – Key Automation

The main control board for a Key Automation sliding gate operator, like the SUN7224 or SUN11024, is the central processing unit that manages the gate's movement, safety features, and other functionalities.

It receives signals from remote controls, keypads, or sensors, and then directs the motor to open or close the gate accordingly.

Here's a more detailed explanation:

-

Core Function:The control board acts as the "brain" of the gate system, interpreting signals and controlling the motor.

-

Input:It receives signals from various input devices, such as remote controls, keypads, or safety sensors.

-

Output:It sends commands to the motor to start, stop, reverse, or adjust its speed based on the input received.

-

Safety Features:Many control boards include safety features like obstacle detection, which can automatically stop or reverse the gate if it encounters an obstruction.

-

Programming and Diagnostics:Some control boards offer programming capabilities and diagnostic displays to simplify setup and troubleshooting.

-

D-Track Technology:Some Key Automation models, like the Deimos, utilize D-Track technology for precise torque management and impact detection.

-

Power Supply:Control boards typically operate on a specific voltage (e.g., 24V DC or 110V AC).

Sliding gate operator main control board – VDS

Ship or pick up from our office.

Sliding gate operator main control board – VDS

The VDS SIMPLY sliding gate operator's main control board is the central unit that controls the operation of a sliding gate, typically one that weighs up to 600kg.

It's made by VDS Automation, an Italian company known for its gate automation products.

This control board manages functions like opening and closing the gate, potentially adjusting speed and force, and integrating with accessories such as keypads and safety sensors.

-

Central Control:The control board acts as the brain of the gate, receiving signals from remote controls or other input devices and translating them into actions for the gate's motor and other components.

-

Remote Control Integration:It typically includes a built-in radio receiver that can be programmed to work with VDS remote controls.

-

Safety Features:The control board can manage safety mechanisms like anti-squashing systems and potentially adjustable speed and force settings.

-

Easy Installation and Programming:The VDS SIMPLY control board is designed for easy installation, often featuring pre-wired components and straightforward programming.

-

Optional Accessories:It can be integrated with optional accessories like keypads, safety sensors, and other components to enhance functionality.

-

Durability:The control unit is often housed in a box with an air-stop seal to protect it from moisture and insects, and the mechanical parts may be lubricated with lithium grease for longevity.

-

Italian Manufacturing:VDS (Simply SL110) is specifically mentioned as an Italian-made control board, emphasizing quality and reliability.

Sliding gate operator main control board – Zero

Ship or pick up from our office.

Sliding gate operator main control board – Zero

The sliding gate operator main control board (also referred to as a PCB or circuit board) is the central component that manages all the functions of an automatic sliding gate system.

It acts as the "brain" of the gate, receiving signals from various input devices (like remote controls, keypads, or safety sensors) and translating them into actions for the gate's motor and other components.

Here's a more detailed breakdown:

1. Central Control: The control board is the central hub for all gate operations. It receives signals from different sources, such as:

- Remote controls: For opening and closing the gate.

- Keypads: For authorized access.

- Safety sensors: To detect obstructions and prevent accidents.

- Other accessories: Such as loop detectors, intercom systems, etc.

2. Signal Processing: The control board interprets the signals it receives and determines the appropriate action for the gate.

3. Motor Activation: Based on the processed signal, the control board sends instructions to the gate's motor to either open or close the gate.

4. Adjustable Settings: The control board often allows for adjustments to various parameters, including:

- Gate speed: The speed at which the gate opens and closes.

- Opening and closing timers: To control the duration of the gate's movement.

- Safety features: Including force adjustments, obstacle detection sensitivity, and slow-down settings.

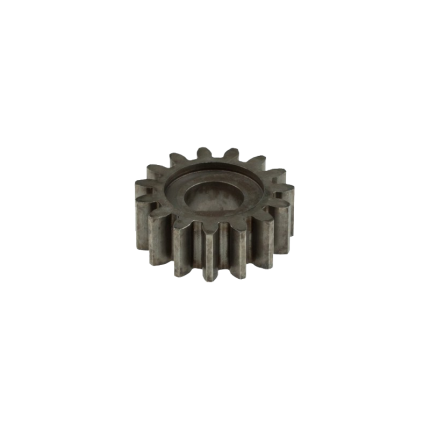

Sliding gate operator’s gear

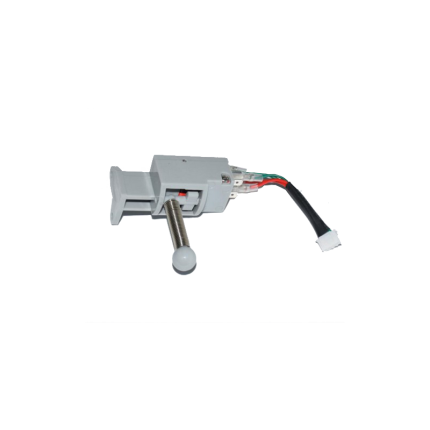

Sliding gate operators limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.

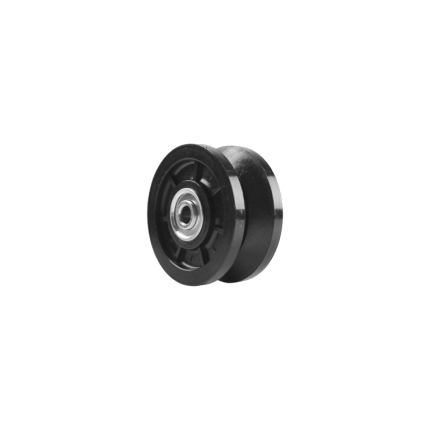

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.