Shop

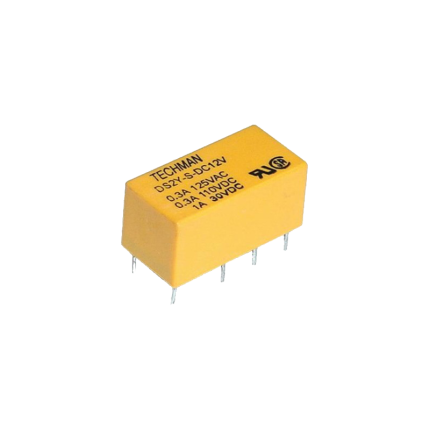

Relay Mini PCB 8-Pin 1A

Ship or pick up from our office.

Relay Mini PCB 8-Pin 1A

A Relay Mini PCB 8-Pin 1A is a small, electronic switch designed to be mounted directly onto a Printed Circuit Board (PCB). It has eight pins for connections and its contacts can safely switch a maximum current of 1 Ampere (1A). Key Characteristics- Miniature Size: The "Mini" in its name indicates its compact dimensions, making it suitable for circuits where space is limited.

- PCB Mountable: It's designed for through-hole soldering onto a PCB, integrating seamlessly into electronic designs.

- 8-Pin Configuration: These pins serve various purposes, including connecting the coil (which activates the relay) and the switch contacts (which control the electrical load).

- 1A Current Rating: This is the maximum current that can safely flow through the relay's contacts when they are closed.

- Coil Voltage: The relay's coil operates on a specific DC voltage (e.g., 3V, 5V, 12V, 24V). Applying this voltage to the coil creates a magnetic field that mechanically opens or closes the contacts.

- Contact Configuration: Many 8-pin mini PCB relays are DPDT (Double Pole, Double Throw), meaning they have two sets of contacts, each with both normally open (NO) and normally closed (NC) positions. This allows for versatile switching operations.

- Isolation: Relays provide electrical isolation between the control circuit (coil) and the load circuit (contacts), enhancing safety and preventing interference.

- Remote Control Systems: Used to switch power to devices based on signals from a remote.

- Communication Equipment: For routing or switching signals in telecommunications and data networks.

- Automatic Control Systems: In automation processes to control motors, lights, or other actuators.

- Household Appliances: Found in various home electronics to manage power to different components.

- Automotive Systems: Employed in vehicles to control functions like lights, locks, and windows.

- Instrumentation and Measurement Devices: For precise signal routing and control in sensitive equipment.

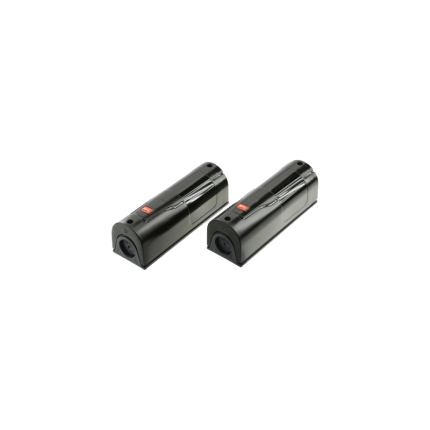

Remote Control Radio Receiver

Ship or pick up from our office.

Remote Control Radio Receiver

- NC/NO Output

- Easy to program new remotes

- The remote control button is covered to prevent accidental pressing.

- This radio receiver can be added to almost all the gate operators such as Italian, Chinese, swing gate operators, sliding gate operators, and overhead garage doors.

- Compatible with 100 remotes.

- Small case and easy to install

- The wireless RF signals can pass through walls, floors, doors, or windows. You can use two or more units in the same place.

A gate opener's remote control radio receiver is a device that receives radio signals from a handheld remote control, triggering the gate opener's motor to open or close the gate.

Here's a more detailed explanation:

-

Receives Signals:The receiver picks up radio waves transmitted by the remote control.

-

Decodes Commands:It interprets the specific signal pattern to understand the desired action (e.g., open, close, stop).

-

Controls Devices:The receiver then sends signals to the gate opener's motor, causing it to move the gate accordingly.

-

Part of a System:It's a crucial component of the remote control system, working with the transmitter (remote) to enable wireless control of the gate.

-

Frequency:Gate opener receivers typically operate on frequencies like 433 MHz or 315 MHz.

-

Installation:The receiver is usually wired to the gate operator's control board and may require programming to associate it with specific remote controls.

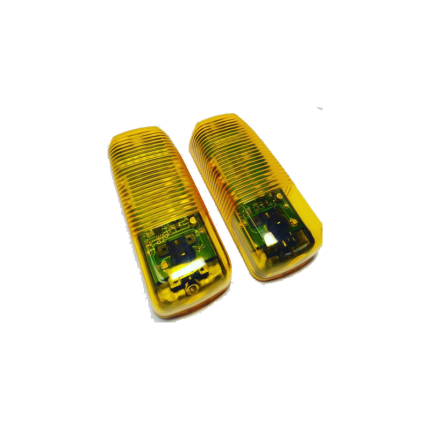

Remote starter immobilizer bypass module

Ship or pick up from our office.

Remote starter immobilizer bypass module

A remote starter immobilizer bypass module is an essential component when installing an aftermarket remote car starter in most modern vehicles. Its sole purpose is to "trick" the vehicle's factory immobilizer system into believing that the correct key is present in the ignition, allowing the engine to start remotely. Here's a breakdown of what that means: What is a remote starter immobilizer bypass module system? Since around the late 1990s, and mandated for all new cars sold in Canada since the year 2000, virtually every vehicle is equipped with an electronic immobilizer system as an anti-theft measure. This system prevents the engine from starting unless it detects a specific, valid code.- How it works:

- Your car key (or smart key fob) contains a small electronic chip called a transponder. This chip stores a unique electronic code.

- When you insert the key into the ignition (or, with push-button start, have the fob within range), the vehicle's onboard computer (often via an antenna coil around the ignition barrel) reads the code from the transponder.

- If the code matches what's stored in the vehicle's ECU (Engine Control Unit), the remote starter immobilizer bypass module is deactivated, and the engine is allowed to start and run.

- If the code doesn't match, or if no valid code is detected (e.g., someone tries to hot-wire the car, or uses an unprogrammed key), the immobilizer will prevent the engine from starting, or it will start for a few seconds and then immediately shut off. It typically disables vital functions like the fuel pump or ignition system.

RFID Card Access Control

Ship or pick up from our office.

RFID Card Access Control

RFID card access control is a system that uses Radio Frequency Identification (RFID) technology to manage and control access to physical spaces. It provides a secure and convenient way to grant or deny entry to authorized individuals, replacing traditional keys or swipe cards. This system works by wirelessly communicating between an RFID card (or tag) and an RFID reader. How it Works- RFID Card (Tag): Each authorized individual carries an RFID card, key fob, or even a smartphone with an embedded RFID chip. This chip contains a unique identification code and sometimes other encrypted data.

- RFID Reader: Readers are installed at entry points (doors, gates, elevators, etc.). They constantly emit a radio frequency field.

- Communication: When an RFID card enters the reader's field, the card's antenna captures energy from the reader's signal. This energizes the microchip on the card, allowing it to transmit its unique data back to the reader.

- Data Verification: The RFID reader decodes the information from the card and sends it to a central access control server or control panel. This server compares the card's data with a secure database of authorized users and their access permissions.

- Access Grant/Denial: If the credentials match an authorized profile, the system sends a signal to an electronic lock mechanism, allowing entry. If not, access is denied. This entire process typically happens in milliseconds.

- Audit Trail: The system also records detailed access information, including the time, date, and specific access point used, providing a valuable audit trail for security purposes.

- RFID Cards/Tags: These are the credentials held by users, typically in the form of plastic cards, key fobs, or even integrated into mobile devices. They contain a microchip and an antenna.

- RFID Readers (Interrogators): Devices installed at entry points that emit radio waves to communicate with the tags and read their data.

- Access Control Panel/Server: This is the "brain" of the system. It receives data from the readers, verifies user credentials against a database, and controls the electronic locks. It can be cloud-based or local.

- Electronic Locks: Devices that secure the entry points and are controlled by the access control system (e.g., magnetic locks, electric strikes).

- Access Control Software: Software used to manage user profiles, set access levels, monitor events, and generate reports.

- Passive RFID Tags: Most common for access control. They don't have an internal battery and are powered by the electromagnetic field emitted by the reader. They have a shorter read range (a few centimeters to a meter).

- Active RFID Tags: These tags have their own power source (battery), allowing for a much longer read range (up to several hundred meters) and the ability to broadcast signals periodically. They are typically more expensive.

- Semi-Passive RFID Tags: These tags have a battery to power the chip but only transmit data when activated by a reader's signal, offering improved sensitivity and performance over passive tags.

- Convenience: Offers contactless and keyless entry, making it fast and easy for users to gain access. Cards can often be read from inside a wallet or bag.

- Enhanced Security: Provides unique identification and can utilize encrypted communication, making tags difficult to duplicate. Lost cards can be immediately deactivated, preventing unauthorized use.

- Efficiency: Streamlines entry and exit processes, reducing wait times, especially in high-traffic areas.

- Flexibility & Scalability: Easily allows for adjusting access permissions for different users, areas, or time frames. Systems can be expanded or modified as needs change.

- Integration: Can be integrated with other security systems like CCTV, alarms, and time attendance systems for comprehensive security management.

- Audit Trails: Provides real-time tracking of who enters and exits, offering valuable data for security monitoring and incident investigation.

- Durability: RFID components generally experience less wear and tear compared to traditional mechanical locks or swipe card systems.

- Skimming: In theory, unauthorized readers could attempt to read card information if they get close enough, though modern RFID cards often use one-time codes and encryption to mitigate this risk.

- Cloning: If the security protocols are weak, an RFID card's information could potentially be cloned.

- Electromagnetic Interference: Other electronic devices or metal/liquid objects can sometimes interfere with RFID signals, impacting performance.

RFID Tag Access Control

Ship or pick up from our office.

RFID Tag Access Control

RFID Tag Access Control is a system that uses Radio Frequency Identification (RFID) technology to manage and control access to physical spaces or logical systems. It allows only authorized individuals or items to enter secure areas by wirelessly reading data stored on RFID tags. Think of it as a modern, electronic key system where your "key" is an RFID tag (like a card or key fob) and the "lock" is an RFID reader. How it Works ⚙️ The fundamental principle is straightforward:- RFID Tag/Credential: Each authorized individual or item is assigned an RFID tag. This tag contains a microchip that stores a unique identification code and an antenna.

- RFID Reader: A reader (also called an interrogator) is installed at the access point (e.g., a door, gate, or turnstile). The reader emits radio waves.

- Communication: When an RFID tag comes within range of the reader's radio waves, the tag's antenna captures energy from the reader's signal (for passive tags) or uses its own power source (for active tags) to activate its microchip. The tag then transmits its unique data back to the reader.

- Data Processing: The reader decodes the information from the tag and sends it to a central access control software or system.

- Authentication and Decision: The software compares the tag's unique ID with a database of authorized users and their assigned permissions. If the ID is valid and the user has permission to access that specific area at that time, the system sends a signal to unlock the door, open the gate, or grant access. If not, access is denied.

- Logging: The system typically logs every access attempt (both granted and denied), providing an audit trail for security monitoring and compliance.

- RFID Tag Access Controls/Credentials: These are the physical devices carried by users. They come in various forms, such as:

- Cards: Similar to credit cards, commonly used for employee badges or hotel key cards.

- Key Fobs: Small, convenient devices attached to keychains.

- Wristbands: Often used in recreational facilities or for events.

- Stickers/Labels: Can be affixed to items or vehicles.

- Mobile Credentials: Increasingly, smartphones can act as RFID tags through NFC (Near Field Communication), a subset of HF RFID.

- RFID Readers: Devices that emit radio waves to energize and read data from RFID tags. They can be fixed (at entry points) or mobile (handheld scanners).

- Antennas: Integral to the reader (or external), they transmit and receive radio signals to and from the tags. The antenna design influences the read range and reliability.

- Access Control Software/Management System: The "brain" of the system. This software manages user databases, assigns access permissions, logs events, and allows administrators to configure and monitor the system remotely.

- Access Control Panel/Controller: Hardware that connects the readers to the central software, processing data and controlling the locking mechanisms.

- Passive RFID Tags:

- Do not have an internal power source.

- They draw power from the radio waves emitted by the reader to operate.

- Are generally smaller, less expensive, and require no maintenance.

- Have a shorter read range (a few centimeters to a few feet).

- Most commonly used in access control for cards and key fobs.

- Active RFID Tags:

- Have their own internal power source (battery).

- Can transmit data over longer distances (up to several hundred meters) and at regular intervals.

- Are larger and more expensive.

- Often used for long-range applications like vehicle tracking or asset management.

- Semi-Passive RFID Tags (Battery-Assisted Passive - BAP):

- Contain a battery to power the microchip, but still rely on the reader's signal to initiate communication.

- Offer better read range and performance than passive tags, without continuously transmitting like active tags.

- Low Frequency (LF) RFID (125-134 kHz):

- Short read range (1-10 cm).

- Less susceptible to interference from metal and water.

- Common in traditional access control systems.

- High Frequency (HF) RFID (13.56 MHz):

- Moderate read range (10 cm-1 meter).

- Widely used for access control, ticketing, and Near Field Communication (NFC) applications (like smartphone taps).

- Ultra-High Frequency (UHF) RFID (300 MHz-3 GHz, often 860-960 MHz for RAIN RFID):

- Long read range (up to 12 meters).

- More susceptible to interference from liquids and metals.

- Used in applications requiring longer read distances, such as vehicle access control or large-scale inventory tracking.

Safety sensor – BFT FL130

Ship or pick up from our office.

Safety sensor - BFT FL130

The BFT FL130 is a photoelectric safety sensor designed primarily for use with automated gates and doors. It's a crucial safety component that prevents the gate or door from closing if an obstacle, such as a person or vehicle, is detected in its path. Here's a breakdown of its key aspects: How it Works The BFT FL130 operates as a pair of photocells, consisting of a transmitter (TX) and a receiver (RX). These units are typically mounted on opposite sides of the gate or door opening. The transmitter emits an infrared beam towards the receiver. If anything breaks this beam (e.g., a person walking through, a car passing), the receiver detects the interruption and sends a signal to the gate's control unit. This signal then triggers a safety mechanism, causing the gate to stop its movement or reverse direction to avoid impact. Features and Specifications- Type: Photoelectric safety sensor (photocell).

- Components: Transmitter and receiver pair.

- Function: Detects obstacles in the path of automated gates and doors to prevent accidents.

- Detection Method: Infrared beam.

- Applications: Commonly used in residential and commercial settings for automated swing gates, sliding gates, and garage doors.

- Max Range: Up to 30 meters (can be reduced by 50% in adverse weather conditions like fog or heavy rain).

- Power Supply: Typically 20-31 VAC or 22-30 VDC.

- Absorption: Approximately 70mA per pair.

- Relay Contacts: 1A at 24 VAC-DC.

- Working Temperature: Generally from -15°C to +70°C (some sources say -5°C to +70°C).

- Protection Rating: IP54, meaning it's protected against dust ingress and splashing water.

- Mounting: Should be aligned and mounted at a height between 40 and 60 cm from the ground on flat, parallel surfaces.

- Dimensions: Compact, typically around 115mm x 32mm x 26mm.

- Versions: There is also a BFT FL130B version, which may offer additional features like self-alignment and is designed to meet EN12453 regulations for Type D safety devices when connected to a compatible control unit that verifies safety device functionality.

Safety Sensor – Key Automation 900FT33

Ship or pick up from our office.

Safety Sensor - Key Automation 900FT33

- NO/NC

- AC 10-30 V / DC 10-40 V

- Receiving Range: 25 Meters

- IP 54

Safety sensor – P51033H

Ship or pick up from our office.

Safety sensor - P51033H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *The safety sensor included the LED flash lightSafety sensor FO-MATIC

Ship or pick up from our office.

Safety sensor FO-MATIC

*NO/NC *AC/DC 12-24 V *Receiving Range: 15 Meters *IP 44Safety sensor FT2008

Ship or pick up from our office.

Safety sensor FT2008

*NO/NC *AC/DC 12-24 V *Receiving Range: 15 Meters *IP 44A gate opener safety sensor is a device designed to detect objects or people in the path of an automatic gate and prevent it from closing or hitting them, ensuring safety and preventing damage or injury.

These sensors can be photoelectric, pressure sensors, magnetic sensors, or loop detectors and are crucial for preventing accidents and ensuring smooth gate operation.

Types of Gate Opener Safety Sensors:

-

Photoelectric Sensors:These sensors use an infrared beam to detect objects. When the beam is broken by an object, the gate opener is signaled to stop or reverse.

-

Pressure Sensors:These sensors are typically located along the edge of the gate and detect pressure when the gate comes into contact with an object.

-

Magnetic Sensors:These sensors use a magnetic field to detect the presence of vehicles or objects near the gate.

-

Loop Detectors:These sensors use a wire loop buried in the ground near the gate. When a vehicle or object passes over the loop, it triggers the gate to stop or reverse.

How They Work:

- Detection: The sensor detects the presence of an object or person in the gate's path.

- Signal: The sensor sends a signal to the gate operator.

- Action: The gate operator responds by stopping, reversing, or remaining open, depending on the sensor type and programmed settings.

Importance of Safety Sensors:

- Prevent Accidents: They protect people and vehicles from being hit by the gate.

- Prevent Damage: They help avoid damage to the gate, vehicles, or property.

- Ensure Reliable Operation: They contribute to the smooth and safe operation of the gate.

Safety sensor P51022H

Ship or pick up from our office.

Safety sensor P51022H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *Internal Rotation system: 0~180Safety Sensor P52000H

Ship or pick up from our office.

Safety Sensor P52000H

IP Rating: IP54

Certification: CE

Working Voltage: 12V-24V AC/DC

Temperature Rane: -20ºC to 60 ºC

Protection Index: IP54

Photocell Wavelength: 940nm

Receiver Range: More Than 12m

Weight: 139g

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.