Sliding gate

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.

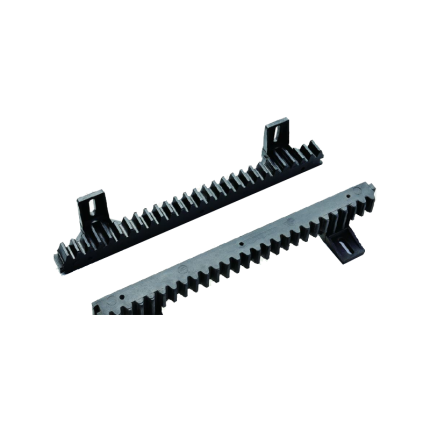

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

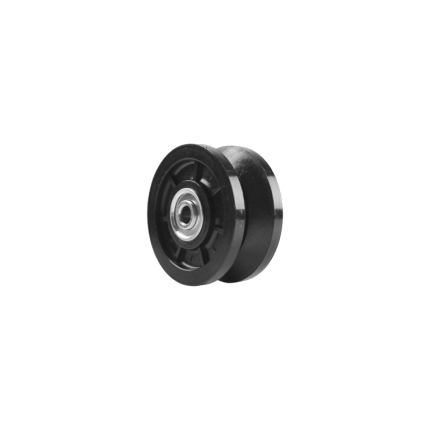

Sliding gate V-Groove nylon wheels -SLGWNS250

Ship or pick up from our office.

*Double bearing *Max 250 Kg *98 mm Diameter (4") x 44 mm Width (1-3/4") (Heavy-duty bolts, nuts, and washers are included)Sliding gate V-Groove nylon wheels -SLGWN778MLB

Support Roller

Ship or pick up from our office.

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.

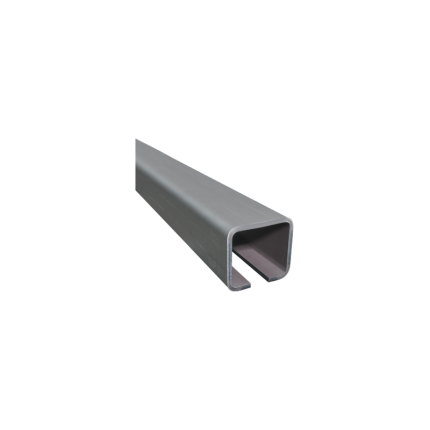

Cantilever sliding gate track

Ship or pick up from our office.

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

Gate Opener Remote Control 1400FT315

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315

*High-Range 1400ft *315 MHz *Compatible with HomeLink system on vehicles *1 channelGate Opener Remote Control 1400FT315/2-CH

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315/2-CH

A high-range gate opener remote control 1400FT315/2-CH allows you to operate your gates from a greater distance than standard remotes, typically offering a range of several hundred feet or even up to a mile or more.

These remotes are often used in situations where the gate is located far from the entrance or when there are obstructions between the remote and the receiver.

Here's a more detailed explanation about Gate Opener Remote Control 1400FT315/2-CH:

What makes it high-range?

-

Stronger Transmitter:High-range remotes have a more powerful transmitter than standard remotes, allowing them to send a stronger signal over a longer distance.

-

Specialized Receiver:These remotes often work with a specialized receiver that is more sensitive and capable of picking up weaker signals.

-

Frequency:High-range remotes typically operate on a specific frequency (e.g., 433MHz or 315MHz) that is less prone to interference and allows for better transmission.

Benefits of high-range remotes like as the Gate Opener Remote Control 1400FT315/2-CH:

-

Increased Convenience:You can open your gate from a greater distance, which is particularly useful for large properties or when driving up to the gate.

-

Improved Security:High-range remotes can help prevent unauthorized access by allowing you to activate the gate from a safe distance.

-

Enhanced Flexibility:They can be used in a wider range of situations, such as when you need to open the gate for deliveries or visitors.

Factors affecting range:

-

Line of Sight:The range is usually maximized when there is a clear line of sight between the remote and the receiver.

-

Obstructions:Walls, trees, and other obstructions can reduce the range of the remote.

-

Weather Conditions:Extreme weather conditions like heavy rain or snow can also affect the range.

-

Antenna Placement:Proper placement of the antenna on the receiver can help improve the range.

Sliding gate operator limit sensor – Magnetic mechanism

Ship or pick up from our office.

Sliding gate operator limit sensor - Magnetic mechanism

A sliding gate operator limit sensor, often a limit switch, is a crucial component that signals the gate operator when the gate has reached its fully open or fully closed position, stopping the motor and preventing over-travel. These sensors ensure the gate stops at the correct positions, preventing damage to the gate and surrounding structure.

Here's a more detailed explanation:

-

Function:Limit sensors, like limit switches, detect when the gate reaches its extreme open or closed positions.

-

How it works:When the gate reaches the limit, the sensor sends a signal to the gate operator's control board, which then stops the motor.

-

Importance:Without limit sensors, the gate might continue to move, potentially hitting the end posts or other obstructions, causing damage.

-

Types:Common types include magnetic limit switches and photoelectric sensors (photo eyes).

-

Magnetic Limit Switches:These utilize magnets placed on the gate and a magnetic sensor on the operator. When the magnet aligns with the sensor, it triggers the limit switch.

-

Photoelectric Sensors (Photo Eyes):These use infrared beams to detect obstructions. When the beam is broken (e.g., by the gate), the sensor signals the operator to stop.

-

Installation:Proper installation and adjustment of limit sensors are crucial for the reliable operation.

-

Maintenance:Regular inspection and maintenance of limit sensors are recommended, as they can wear out or become misaligned over time.

Sliding gate V-Groove wheels -SLGWS800

Ship or pick up from our office.

Sliding gate V-Groove wheels -SLGWS800

Sliding gate V-Groove wheels are a fundamental component in a common type of sliding gate system. Unlike cantilever gates that hang above the ground, these gates roll directly on a track installed on the ground. Here's a detailed explanation: What they are: A V-Groove wheel is a type of wheel specifically designed with a V-shaped groove machined into its circumference. This groove perfectly mates with a corresponding V-shaped track, which is usually made of angle iron or a similar steel profile. How they work:- Track Installation: A V-shaped steel track is securely laid and typically anchored into the driveway or ground along the entire length of the gate's travel path. This track acts as the "railroad track" for the gate.

- Wheel Attachment: The V-Groove wheels are attached to the bottom frame of the sliding gate. Depending on the gate's length and weight, multiple wheels will be strategically placed along its underside.

- Guidance and Support: As the gate opens or closes (either manually or with a gate opener), the V-shaped groove of the wheels sits snugly onto the V-shaped track. This tight fit ensures:

- Smooth and Stable Movement: The gate rolls smoothly and without wobbling or derailing.

- Guidance: The wheels effectively guide the gate in a straight line, preventing it from veering off course.

- Load Distribution: The wheels bear the weight of the gate, distributing it evenly along the track.

- Materials: V-Groove wheels are typically made from durable materials to withstand heavy loads and wear:

- Steel (most common): Offers high strength, load capacity, and durability. Often zinc-plated or galvanized for corrosion resistance.

- Cast Iron: More economical but can be more prone to breakage than steel, and may require more frequent lubrication.

- Nylon or High-Impact Polymer: Quieter in operation and excellent for corrosion resistance, but generally have lower load capacities than steel and may not last as long under heavy use.

- Bearings: High-quality V-Groove wheels incorporate sealed bearings (like precision ball bearings). These reduce friction, ensure smooth rolling, and often require no lubrication, making them "maintenance-free."

- Sizes: Available in various diameters (e.g., 3", 4", 6") and load capacities (ranging from hundreds to thousands of pounds per wheel) to suit different gate sizes and weights.

- With or Without Brackets: Some wheels come with integrated mounting brackets for easier installation, while others are just the wheel itself, requiring a custom bracket or housing.

- Stability and Alignment: The V-groove design provides excellent stability, keeping the gate perfectly aligned with the track and preventing it from tilting or derailing.

- High Load Capacity: Especially steel V-Groove wheels, they are designed to handle very heavy gates, making them suitable for large residential, commercial, and industrial applications.

- Durability and Longevity: Made from robust materials, they offer a long service life, particularly with sealed bearings.

- Relatively Simple System: The concept is straightforward, and the components are widely available.

- Ground Track Maintenance: The main drawback compared to cantilever gates is that the ground track can accumulate debris (leaves, dirt, snow, ice). This debris must be regularly cleaned to ensure smooth operation and prevent damage to the wheels or opener. In Surrey, BC's climate, this is an important consideration due to rain and potential for snow.

- Driveway Disruption: Installing a ground track requires cutting into or modifying the driveway surface.

- Noise: While smoother than some other wheel types, they can still produce some noise, particularly if the track is not perfectly clean or if the wheels are worn.

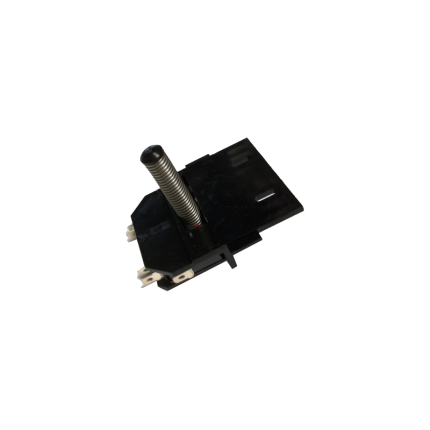

Sliding gate operator limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.

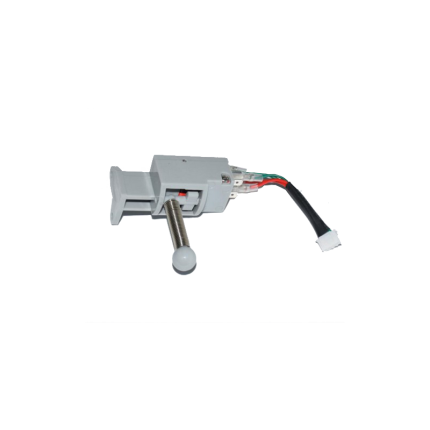

Sliding gate operators limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.