Sliding gate

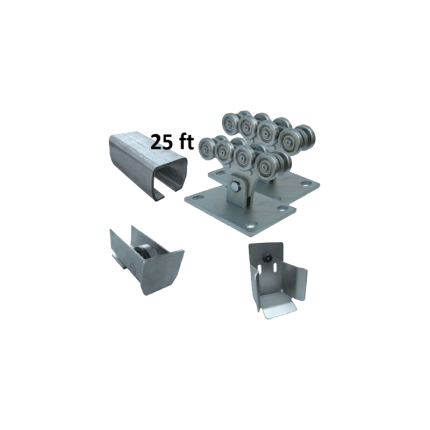

Cantilever Sliding Gate Hardware

Ship or pick up from our office.

Cantilever Sliding Gate Hardware

Cantilever sliding gate hardware refers to the specialized components that allow a gate to slide open and close without needing a track on the ground. Instead, the gate is supported and guided from above and to the side by a system of rollers and channels. Here's a breakdown of the essential components that make up cantilever sliding gate hardware:- Cantilever Track (or Rail):

- This is the most distinctive part. It's a heavy-duty, usually C-shaped (or sometimes a more complex extruded profile) channel that's securely attached to the bottom (or sometimes top) of the gate frame itself.

- The track is extended beyond the main gate opening to form the "tail" or counterbalance section, which supports the gate when it's fully open.

- Materials: Commonly made from galvanized steel for strength and corrosion resistance, or aluminum for lighter weight and superior corrosion resistance (as discussed previously).

- Cantilever Carriages (or Trolleys/Rollers):

- These are the critical load-bearing components. They consist of a sturdy base plate with multiple wheels (often 5, 8, or more) arranged in a specific configuration.

- The wheels are made from durable materials like steel (often machined or cast) or high-impact nylon, and typically feature sealed bearings for smooth, maintenance-free operation.

- The cantilever track fits over these carriages, with the wheels rolling inside the track's channel.

- Two (or more for very long/heavy gates) carriages are typically mounted on strong concrete foundation posts, positioned outside the gate opening. These posts support the entire weight of the gate.

- Guide Rollers/Plates (Upper Guides):

- These are smaller rollers or plates mounted on a separate guide post (or posts) on the same side as the cantilever carriages.

- Their purpose is to keep the gate upright and prevent it from tipping over as it moves. They typically engage with the top rail of the gate.

- Made from nylon, steel, or a combination, often with adjustable brackets.

- End Cups / Receiver Posts / Gate Catches:

- End Cup (or End Stop): A cup or bracket mounted on the support posts at the fully closed position. The end of the gate's tail section (specifically the track) "rests" in this cup when the gate is fully closed, providing additional stability and support.

- Receiver Post / Gate Catch: A post or latching mechanism at the opposite end of the gate opening. When the gate is fully closed, it engages with this post to secure the gate in the closed position. This is often where a lock or the gate operator's arm connects.

- Support Wheels / Final Wheels: Sometimes, a small support wheel is mounted on the ground or a low post at the far end of the gate opening to provide extra support to the gate's leading edge when it's fully closed, especially for very long or heavy gates.

- Anchoring and Installation Accessories:

- Foundation Plates/Anchor Bolts: Heavy-duty plates and bolts used to securely anchor the cantilever carriages to concrete foundations. The stability of the entire system relies on robust anchoring.

- Tension Bars (less common in modern designs): Historically used for minor adjustments to gate alignment or sag, though modern systems are often designed to minimize this need.

- No Ground Track: This is the primary advantage. Eliminates the need for a track embedded in the driveway, which means:

- No debris accumulation (leaves, dirt, snow, ice) obstructing movement.

- Smoother operation on uneven driveways.

- Less maintenance in terms of track cleaning.

- No tripping hazard or wear on vehicles crossing a ground track.

- Durability and Low Maintenance: Because the main rolling components (carriages) are elevated and enclosed within the track, they are less exposed to dirt and weather, leading to longer life and less frequent maintenance.

- High Security: Cantilever gates are inherently very secure as they are difficult to lift or derail.

- Aesthetics: The absence of a ground track can contribute to a cleaner, more streamlined look for the driveway entrance.

- Suitable for High-Traffic Areas: Their robust design makes them ideal for commercial, industrial, or busy residential applications.

- Gate Automation and Supply Companies: Businesses specializing in automatic gates will carry a full range of cantilever hardware. Examples include Royal Gates (Royal Electronic Technology Center Co.), presence in the Metro Vancouver area, including Surrey.

- Fencing and Gate Fabricators: Many companies that custom-fabricate gates will also supply or install the necessary hardware.

- Industrial Hardware Suppliers: Larger industrial suppliers may stock components, though specialized gate companies will offer more comprehensive systems.

- Online Retailers: Many online suppliers ship to Canada, offering a wide variety of components from different manufacturers.

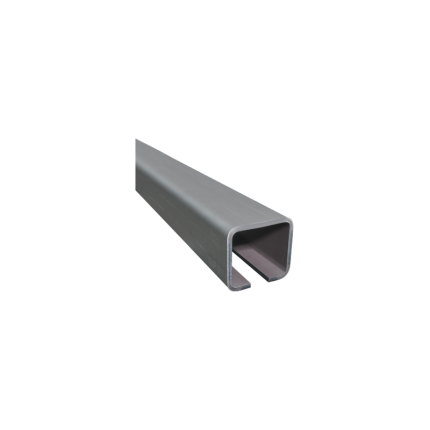

Cantilever sliding gate track

Ship or pick up from our office.

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

Gate Opener Remote Control 1400FT315

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315

*High-Range 1400ft *315 MHz *Compatible with HomeLink system on vehicles *1 channelGate Opener Remote Control 1400FT315/2-CH

Ship or pick up from our office.

Gate Opener Remote Control 1400FT315/2-CH

A high-range gate opener remote control 1400FT315/2-CH allows you to operate your gates from a greater distance than standard remotes, typically offering a range of several hundred feet or even up to a mile or more.

These remotes are often used in situations where the gate is located far from the entrance or when there are obstructions between the remote and the receiver.

Here's a more detailed explanation about Gate Opener Remote Control 1400FT315/2-CH:

What makes it high-range?

-

Stronger Transmitter:High-range remotes have a more powerful transmitter than standard remotes, allowing them to send a stronger signal over a longer distance.

-

Specialized Receiver:These remotes often work with a specialized receiver that is more sensitive and capable of picking up weaker signals.

-

Frequency:High-range remotes typically operate on a specific frequency (e.g., 433MHz or 315MHz) that is less prone to interference and allows for better transmission.

Benefits of high-range remotes like as the Gate Opener Remote Control 1400FT315/2-CH:

-

Increased Convenience:You can open your gate from a greater distance, which is particularly useful for large properties or when driving up to the gate.

-

Improved Security:High-range remotes can help prevent unauthorized access by allowing you to activate the gate from a safe distance.

-

Enhanced Flexibility:They can be used in a wider range of situations, such as when you need to open the gate for deliveries or visitors.

Factors affecting range:

-

Line of Sight:The range is usually maximized when there is a clear line of sight between the remote and the receiver.

-

Obstructions:Walls, trees, and other obstructions can reduce the range of the remote.

-

Weather Conditions:Extreme weather conditions like heavy rain or snow can also affect the range.

-

Antenna Placement:Proper placement of the antenna on the receiver can help improve the range.

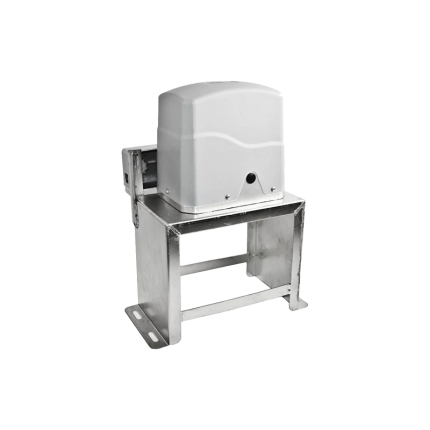

Sliding gate opener – Royalgate RGSL2TO

Ship or pick up from our office.

Sliding gate opener –Royalgate RGSL2TO

Sliding gate opener – Royalgate RGSLC400

Ship or pick up from our office.

Sliding gate opener - Royalgate RGSLC400

A chain-link sliding gate opener is a mechanical device that automates the opening and closing of a chain-link fence gate, allowing it to slide open and closed along a track rather than swinging.

It typically uses a chain drive system to move the gate, providing a convenient and often more secure access solution.

Here's a more detailed explanation:

What it is:

-

Automation:It's an automated system that eliminates the need to manually open and close a sliding chain-link gate.

-

Chain Drive:The most common type uses a chain drive, similar to a bicycle chain, to propel the gate along a track.

-

Track and Wheels:The gate slides on a track, usually supported by rollers or wheels, allowing for smooth movement.

-

Security and Convenience:Sliding gate openers provide security by limiting access and offer convenience by allowing remote or automated operation.

How it works:

- Motor and Gearbox: An electric motor and gearbox drive the chain.

- Chain Movement: The motor rotates a sprocket, which moves the chain.

- Gate Movement: The chain is connected to the gate, and its movement along the track pulls or pushes the gate open or closed.

- Control System: A control system, which can include remote controls, keypads, or sensors, manages the gate's operation.

Types of Sliding Gates (relevant to openers):

- Cantilever Gates: These gates slide horizontally on rollers, with a portion of the gate extending beyond the opening to act as a counterbalance.

- Rolling Gates: These gates roll along a track, often used when space is limited.

Benefits:

- Space Efficiency: Sliding gates require less space than swing gates, especially for wider openings.

- Security: Automated systems offer enhanced security and controlled access.

- Convenience: Remote or automated operation provides ease of use.

- Durability: Chain drive systems are known for their durability and reliability.

Considerations:

- Gate Weight and Size: The opener needs to be compatible with the gate's weight and size.

- Power Source: Consider whether you need an AC or DC motor, or even a solar-powered option.

- Control System: Choose a control system that suits your needs (remotes, keypads, etc.).

Sliding gate opener – VDS Carrera SL800

Ship or pick up from our office.

Sliding gate opener - VDS Carrera SL800

Suitable gate weight: Maximum 800 Kg Included:- 1 x Electromechanical motor

- 1 x Main control board

- 4 Meters x SLGR41 Gear rack

- 2 x Remote control

- 2 x Manual release key

- 1 x Base Plate

- 2 x Limit Switch bracket

- Installation Manual

- Programming Manual

Key Features of the VDS Carrera Gate Openers:

-

Sliding Gate Compatibility:The Carrera series is designed for sliding gates, utilizing a gear rack-driven mechanism.

-

Weight Capacity:Models are available for gates weighing up to 800 kg (Carrera 800) and 1000 kg (Carrera 1000).

-

Robust Construction:The motors feature steel and cast iron gears, lubricated with lithium grease for corrosion resistance and quiet operation, according to VDS Automation.

-

Control and Safety:They include a control unit with an air-stop seal, anti-squashing system, and options for electronic torque control and slowing down.

-

Easy Programming:The pre-wired systems are designed for easy programming and installation.

-

Optional Accessories:Keypads, remote control radio receivers, and safety sensors can be integrated.

-

Made in Italy:VDS Automazioni is an Italian company that emphasizes the quality and safety of its products.

-

Manual Release:A manual release lever with a custom key is included for emergency situations.

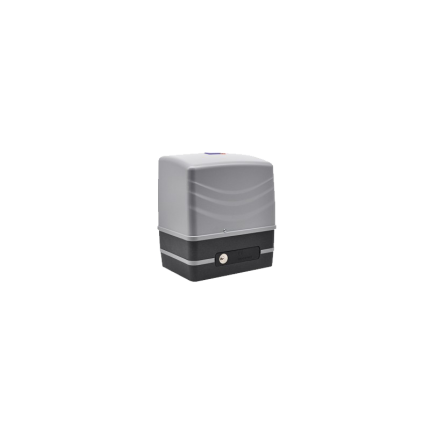

Sliding gate opener – Zero ZSL600

Ship or pick up from our office.

Sliding gate opener - Zero ZSL600

The Zero ZSL600 is a sliding gate opener primarily designed for residential or light commercial use.

It's likely a specific model or series offered by Royal Electronics Technology Center Co. This type of opener is used to automate the sliding motion of gates, typically for driveways, and can be controlled remotely.

Here's a more detailed breakdown:

Key Features & Functions:

-

Sliding Gate Automation:The ZSL600 is specifically designed to automate the sliding motion of a gate along a track.

-

Remote Control:It likely uses a remote control (possibly WiFi-enabled) to open and close the gate, allowing for convenient operation from a distance.

-

Safety Features:Many sliding gate openers include safety mechanisms like infrared sensors and obstacle detection to prevent accidents.

-

Adjustable Settings:The ZSL600 might offer adjustable features like soft start/stop, motor torque, and automatic closing times.

-

Universal Compatibility:The control board may be compatible with various household appliances or industrial devices beyond just gate openers.

-

Surveillance Integration:Some models, like the ZSL600, might be designed to integrate with surveillance cameras for added security.

Typical Applications:

-

Residential Driveways:Automating the opening and closing of driveway gates for convenience and security.

-

Light Commercial Settings:Suitable for properties with moderate traffic and where automated gate operation is desired.

-

Various Household Appliances:Potential for controlling other devices like lights, water pumps, or automatic feeders.

Important Considerations:

-

Installation:Sliding gate openers typically require professional installation to ensure proper alignment, safety, and functionality.

-

Maintenance:Regular maintenance, such as lubrication and checking safety sensors, is important for optimal performance and longevity.

-

Power Source:The ZSL600 is likely designed to operate on a standard power supply (110V AC ).

-

Manual Override:Most gate openers, including the ZSL600, include a manual release mechanism for use in case of power outages or system failures.

Sliding gate opener -Difermatic DSL600

Ship or pick up from our office.

Sliding gate opener -Difermatic DSL600

Sliding gate opener -HiGate HGSL1T

Ship or pick up from our office.

Sliding gate opener –HiGate HGSL1T

Sliding gate opener -Key Automation SUN7224

Ship or pick up from our office.

Product Sheet PDFSliding gate opener -Key Automation SUN7224

Electromechanical gear motor for sliding gates up to 700 kg:

- With a slowdown function both in opening and closing to preserve gate integrity

- Electronic and mechanical parts are well protected from external agents

- Easy maintenance thanks to the horizontal control unit position

- High technological materials resistant to weather conditions

- Gear reduction with an extra-large bearing with high performance

- Extremely silent mechanics, protected by a robust die-cast and powder-coated aluminum body

- With 24 Vdc control unit CT10224

- The release system is ergonomic, efficient, and easily accessible

- Opens gates weighing up to 700 kg

- Easy to install and programming

- Get the desired torque and tension by adjusting the parameters

- Easy to add new remotes

- Emergency release key in case of power failure

- Stop/Reverse in case of obstruction during gate closing

- Built-in adjustable auto-close

- Reliable spring limit sensor for easy adjustment

- Optional accessories such as keypads, remote control radio receivers, and safety sensors can also be integrated