sensor

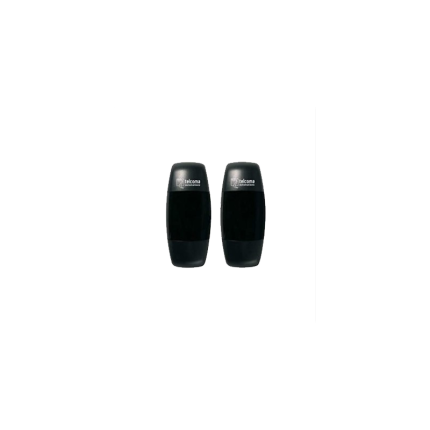

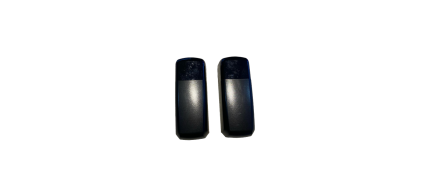

Safety sensor – V2 Sensiva XS

Ship or pick up from our office.

Safety sensor - V2 Sensiva XS

*NO/NC *AC 12-24 V / DC 21-36 V *Receiving Range: 20 Meters *IP 44 Discover the SENSIVA V2 Safety Sensor The SENSIVA V2 photocells are innovative safety devices designed to provide optimal protection for your automated gates and garage doors. Using an infrared beam, they efficiently detect obstacles to stop or reverse the gate's movement, thus preventing any risk of collision or accident. With their compact design and advanced synchronization technology, they easily integrate into any type of installation, offering a reliable and durable solution for both indoor and outdoor environments. Technical Specifications- Power Supply: 12-24 V AC / 12-36 V DC

- Range: Up to 20 meters for the SENSIVA-XS model, and 25 meters for the standard SENSIVA model

- Protection Rating: IP54, resistant to dust and water splashes

- Orientation: Head adjustable horizontally up to 180° and vertically up to 30° (SENSIVA only)

- Dimensions: 84 x 29 x 24 mm (SENSIVA-XS) and 86 x 41 x 38 mm (SENSIVA)

- Operating Temperature: -20°C to +60°C

- Manual: Digital (QR Code) with simple and quick installation

- Maximum Safety: Accurate and reliable obstacle detection to prevent accidents.

- Synchronization: Advanced technology to prevent interference between multiple pairs of photocells.

- Versatile Installation: Compatible with wall or post installations (SENSIVA-XS).

- Weather Resistance: IP54 rating and optimal operation under extreme conditions.

- Adjustable Orientation: Easy configuration to fit all installations (SENSIVA model).

- Reliability: Ensure the safety of your automated gates with precise and effective obstacle detection.

- Modern Technology: Anti-interference synchronization and protection against sunlight.

- Durability: Resistant to wear and weather conditions thanks to robust design and high-quality materials.

- Flexibility: Two models to meet all needs: compact (SENSIVA-XS) or standard (SENSIVA).

Safety sensor FO-MATIC

Ship or pick up from our office.

Safety sensor FO-MATIC

*NO/NC *AC/DC 12-24 V *Receiving Range: 15 Meters *IP 44 The Safety sensor FO-MATIC is a type of photocell safety sensor primarily used in automatic door and gate systems. It's designed to prevent accidents by detecting obstructions in the path of a closing door or gate. How it Works The FO-MATIC sensor operates using a photoelectric principle. It consists of two main components:- Transmitter: Emits an invisible infrared light beam.

- Receiver: Detects the infrared beam.

- Infrared Beam Barrier: Creates a safety zone that, when breached, halts door/gate operation.

- Digital Coding: Often features digital coding on two channels (A or B) to prevent interference from other sensors or light sources.

- Double Relay: Incorporates a double relay for switching contacts, enhancing reliability.

- Versatile Functionality: Can be used for both safety (preventing impacts) and anti-theft purposes (detecting unauthorized entry).

- Robust Design: Typically housed in a durable polycarbonate shell, and some models are designed to be weather-resistant (e.g., IP44 rated).

- Easy Installation: May include features like proportional LED alignment for simpler and safer setup.

- Wide Compatibility: Designed to be compatible with various automatic gate and door operators, including single swing, double swing, and sliding gates.

- Garage doors

- Sliding gates

- Swing gates

- Automatic pedestrian doors

Safety sensor FT2008

Ship or pick up from our office.

Safety sensor FT2008

*NO/NC *AC/DC 12-24 V *Receiving Range: 15 Meters *IP 44A gate opener safety sensor is a device designed to detect objects or people in the path of an automatic gate and prevent it from closing or hitting them, ensuring safety and preventing damage or injury.

These sensors can be photoelectric, pressure sensors, magnetic sensors, or loop detectors and are crucial for preventing accidents and ensuring smooth gate operation.

Types of Gate Opener Safety Sensors:

-

Photoelectric Sensors:These sensors use an infrared beam to detect objects. When the beam is broken by an object, the gate opener is signaled to stop or reverse.

-

Pressure Sensors:These sensors are typically located along the edge of the gate and detect pressure when the gate comes into contact with an object.

-

Magnetic Sensors:These sensors use a magnetic field to detect the presence of vehicles or objects near the gate.

-

Loop Detectors:These sensors use a wire loop buried in the ground near the gate. When a vehicle or object passes over the loop, it triggers the gate to stop or reverse.

How They Work:

- Detection: The sensor detects the presence of an object or person in the gate's path.

- Signal: The sensor sends a signal to the gate operator.

- Action: The gate operator responds by stopping, reversing, or remaining open, depending on the sensor type and programmed settings.

Importance of Safety Sensors:

- Prevent Accidents: They protect people and vehicles from being hit by the gate.

- Prevent Damage: They help avoid damage to the gate, vehicles, or property.

- Ensure Reliable Operation: They contribute to the smooth and safe operation of the gate.

Safety sensor P51022H

Ship or pick up from our office.

Safety sensor P51022H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *Internal Rotation system: 0~180 The P51022H is a safety sensor, specifically a photoelectric sensor, commonly used in automated gate and garage door opener systems. Functionality Like most photoelectric safety sensors, the P51022H works by:- Transmitting an infrared light beam: One part of the sensor (the emitter) sends out an invisible light beam.

- Receiving the beam: The other part of the sensor (the receiver) is designed to detect this beam.

- Obstruction detection: If something breaks the infrared beam while the gate or door is closing, the receiver instantly signals the opener to stop or reverse its movement. This prevents the door or gate from closing on people, pets, or objects, thus enhancing safety and preventing damage.

- Automated gate openers: For both single swing and sliding gates, ensuring they don't close on anything in their path.

- Garage door openers: A mandatory safety feature in most modern residential garage doors, preventing accidents.

- Type: Photoelectric sensor (often referred to as "photo eyes" or "safety beams").

- Components: Typically comes as a kit including a sending sensor (emitter) and a receiving sensor.

- Installation Height: These sensors are usually installed a few inches (e.g., 6 inches) above the ground to effectively detect obstacles, including small children or pets.

- Voltage: Similar sensors often operate on 12-24V AC/DC.

Safety Sensor P52000H

Ship or pick up from our office.

Safety Sensor P52000H

IP Rating: IP54

Certification: CE

Working Voltage: 12V-24V AC/DC

Temperature Rane: -20ºC to 60 ºC

Protection Index: IP54

Photocell Wavelength: 940nm

Receiver Range: More Than 12m

Weight: 139g

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

Safety Sensor S300

Ship or pick up from our office.

Safety Sensor S300

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

Safety sensor VDS-TEC2

Ship or pick up from our office.

Safety sensor VDS-TEC2

Technical Details:- NO/NC

- AC/DC 12-24 V

- Receiving Range: 15 Meters

- IP 44

- Compact

- Lightweight

- Portable

- Easy to use

- Function: It works by emitting an infrared light beam between two units: a sender and a receiver. If an object (like a person or vehicle) breaks this invisible beam, the sensor detects the interruption.

- Safety Feature: When the beam is broken, the VDS-TEC2 sends a signal to the gate's control board. This triggers an action, most commonly preventing the gate from closing to avoid accidents or activating an alarm.

- Applications: Its main application is in enhancing the safety of automated gates and doors in various settings, ensuring that they don't close on obstructions. It is compatible with different models of gate openers.

- Technical Specifications:

- Contacts: NO/NC (Normally Open/Normally Closed)

- Power Supply: AC/DC 12-24 V

- Receiving Range: Up to 15 meters (this range can be reduced in adverse weather conditions like fog, rain, or dust).

- IP Rating: IP44 (meaning it's protected against solid objects larger than 1mm and against splashing water from any direction).

- Design: It's described as compact, lightweight, portable, and easy to use.

Safety sensor VEDO180

Ship or pick up from our office.

Safety sensor VEDO180

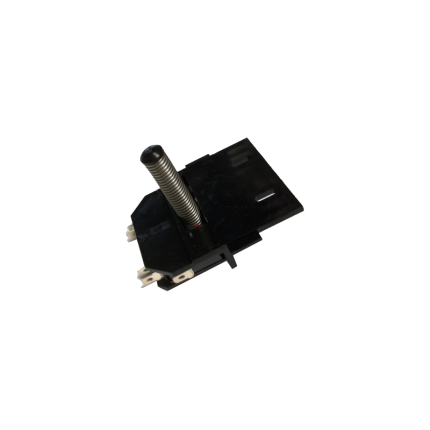

*NO/NC *AC/DC 12-24 V *Receiving Range: 25 Meters *IP 44Sliding gate operator limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.

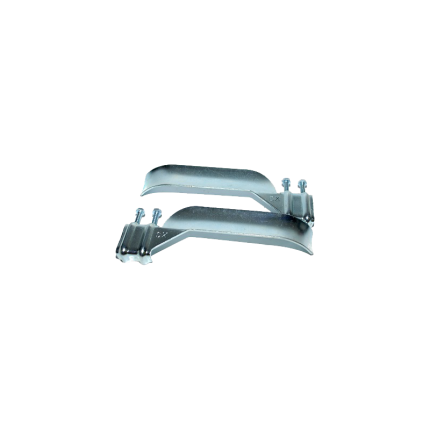

Sliding gate operator limit stopper bracket

Ship or pick up from our office.

Sliding gate operator limit stopper bracket

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and needs only to be cleaned or readjustment.A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions.

These brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track.

Here's a more detailed explanation:

-

Purpose:The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling.

-

How it works:The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor.

-

Components:

- Bracket: The physical structure that holds the sensor.

- Sensor: A device (often a magnet) that interacts with the limit switch.

- Limit Switch: A switch on the gate operator's control board that is activated by the sensor.

- Bracket: The physical structure that holds the sensor.

-

Importance:

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

- Reliability: Ensures consistent and reliable gate operation by defining the travel limits.

- Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

Sliding gate operators limit sensor -Spring

Ship or pick up from our office.

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.

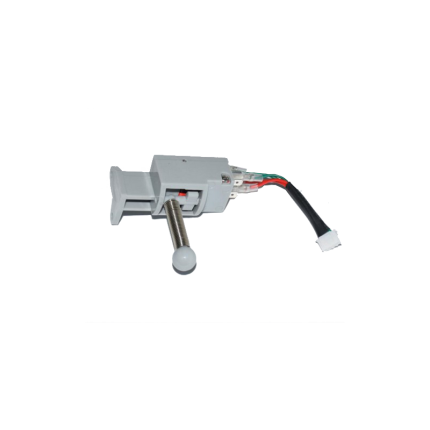

Wireless safety sensor P51122H

Ship or pick up from our office.

Wireless safety sensor P51122H

(2 x AA Batteries are included) *NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 45 The P51122H is a wireless safety sensor primarily used in automatic gate and door systems, such as those for garages and industrial entrances. It's part of a broader wireless system designed to enhance safety by detecting obstructions and preventing damage or injury. 🚧 Key Features & Functionality The P51122H sensor operates on the 2.4 GHz spectrum, making it suitable for global use and allowing multiple installations to coexist without interference. Here are some of its key characteristics:- Wireless Operation: It eliminates the need for wires running across the opening, simplifying installation.

- Safety Assurance: The sensor creates an invisible detection zone. If this zone is interrupted by an object or person while the gate/door is closing, the system will automatically stop or reverse its movement.

- Universal Compatibility: It's designed to work with most door and gate reversing systems.

- Easy Installation: Installation typically involves a simple pairing process with a wireless host module.

- Durable Design: The components are housed in a robust, industrial-grade casing, often with an IP65 rating for water and dust resistance, and a UL Type 4x Enclosure for environmental and physical protection.

- Battery Powered: It runs on AA batteries, with a low battery indicator and a long battery life (up to 10 years in some systems). The battery voltage is monitored, and if abnormal, motion can be denied for safety.

- Compliance: It's typically FCC and IC licensed and cUR recognized, meeting safety standards like UL325.

- Range: It generally has a line-of-sight range of about 150 feet.

- Garage doors: Preventing the door from closing on vehicles, people, or pets.

- Automatic gates: Used for swing gates, sliding gates, and other automated entry systems to prevent collisions.

- Industrial doors and docks: Ensuring safe operation in commercial and industrial environments.