power

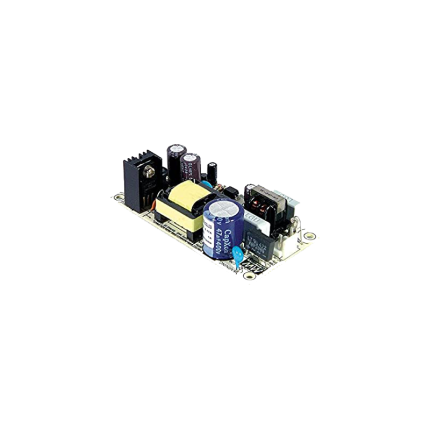

Power converter – AC 24 V to DC 12 V

Ship or pick up from our office.

Power converter - AC 24 V to DC 12 V

A power converter - AC 24 V to DC 12 V is a device that transforms alternating current (AC) at 24 volts into direct current (DC) at 12 volts. These are also commonly referred to as AC/DC power adapters or rectifiers. How it Works ⚙️ The conversion process from AC to DC typically involves several key stages:- Step-Down Transformer: The 24V AC input first goes through a transformer. This component reduces the voltage from 24V AC to a lower AC voltage, although not necessarily directly to 12V DC at this stage. It's about getting to a more manageable voltage level for the subsequent steps.

- Rectification: The reduced AC voltage then enters a rectifier circuit, usually made of diodes. Diodes allow current to flow in only one direction, effectively converting the alternating current (which periodically reverses direction) into a pulsating direct current (which flows in one direction but isn't smooth).

- Half-wave rectifiers block half of the AC waveform.

- Full-wave rectifiers (like a bridge rectifier) use both halves of the AC waveform, resulting in a smoother, more efficient conversion.

- Smoothing (Filtering): The pulsating DC output from the rectifier isn't perfectly steady. It has "ripples" or fluctuations. To smooth this out, capacitors are used. These components store electrical energy during the peaks of the waveform and release it during the dips, creating a much more stable and continuous DC voltage.

- Voltage Regulation: Finally, a voltage regulator circuit ensures that the output voltage remains consistently at the desired 12V DC, regardless of minor fluctuations in the input AC voltage or changes in the load connected to the converter. This also helps protect the connected device from voltage spikes or drops.

- CCTV cameras and surveillance systems: Many security cameras operate on 12V DC, and these converters allow them to be powered from a 24V AC power supply (which is often used in larger installations for longer cable runs due to less voltage drop).

- Low-voltage lighting: Converting 24V AC to 12V DC for certain LED lights or other low-voltage lighting systems.

- Industrial control systems: Some industrial equipment or sensors might use 12V DC power while the facility's power supply is 24V AC.

- Automotive accessories (with specific input needs): While most car systems are 12V DC, there might be niche applications where a 24V AC source needs to be converted.

- Various electronic projects and devices that require a stable 12V DC supply from an AC input.

Power converters – AC 24 V to DC 15 V

Ship or pick up from our office.

Power converters - AC 24 V to DC 15 V

A "Power converter - AC 24 V to DC 15 V" is a device that transforms an alternating current (AC) input of 24 volts into a direct current (DC) output of 15 volts. Here's a breakdown of what that means and how it works: AC (Alternating Current): This is the type of electricity typically supplied by wall outlets in homes and businesses. The voltage constantly changes direction, flowing back and forth. 24V AC is a common voltage for certain low-voltage control systems, industrial equipment, and sometimes HVAC systems. DC (Direct Current): This is the type of electricity that flows in only one direction. Most electronic devices, like phones, laptops, and many sensors or control circuits, require DC power. How an AC to DC Converter Works: An AC to DC converter (also known as a rectifier or power supply) typically involves several stages:- Step-Down Transformer: The initial 24V AC is usually too high for direct conversion to 15V DC. A transformer "steps down" this AC voltage to a lower, more manageable AC voltage.

- Rectification: This is the core of the AC to DC conversion. Diodes are used to convert the alternating current into a pulsating direct current. There are different types of rectifiers (half-wave, full-wave, bridge) that achieve this with varying degrees of efficiency and ripple.

- Smoothing (Filtering): The pulsating DC output from the rectifier isn't perfectly smooth. Capacitors are used to "smooth out" these ripples, creating a more stable DC voltage.

- Regulation: To ensure a precise and constant 15V DC output, a voltage regulator is often employed. This circuit maintains the output voltage at the desired level, even if the input voltage fluctuates or the load on the power supply changes.

- Industrial control systems: Powering sensors, actuators, and control circuits that operate on 15VDC.

- HVAC systems: Often 24VAC is used for thermostats and control panels, but some components within the system might require 15VDC.

- Security systems: Powering cameras, access control devices, and other equipment.

- Lighting systems: Especially in specialized LED lighting setups.

- Custom electronics projects: Where a stable 15VDC is needed from an existing 24VAC infrastructure.

- Output current (Amps): How much current the connected device needs.

- Power rating (Watts): The total power the converter can deliver.

- Efficiency: How much energy is lost during the conversion process (higher efficiency means less heat and less wasted energy).

- Protection features: Over-voltage, over-current, short-circuit protection for safety and device longevity.

- Form factor: Whether it's an open-frame, enclosed, or DIN-rail mount design.

Power inverter 110 V to 220 V

Ship or pick up from our office.

Power inverter 110 V to 220 V

A power inverter 110V to 220V (also known as a step-up voltage converter) is an electronic device that transforms an input voltage of 110 volts (V) into an output voltage of 220V. This type of inverter is crucial for bridging the gap between different regional electrical standards. How It Works At its core, a 110V to 220V power inverter utilizes a transformer to achieve the voltage conversion. Here's a simplified explanation:- Input (DC to AC Conversion for Inverters): While the prompt asks about a "power inverter 110V to 220V," it's important to clarify that traditional inverters convert DC (Direct Current) from a battery (e.g., 12V, 24V, 48V) into AC (Alternating Current). If the input is already 110V AC, then the device is more accurately called a voltage converter or transformer, as it's stepping up AC to AC. However, some inverters are designed to take a DC input and produce 110V AC or 220V AC, or even both.

- Step-Up Transformation: For a 110V AC to 220V AC conversion, the device contains a transformer with primary and secondary coils. The 110V AC from the power source is fed into the primary coil. Through electromagnetic induction, this voltage is "stepped up" to 220V in the secondary coil, which then becomes the output.

- Waveform: Inverters and converters can produce different types of AC waveforms:

- Pure Sine Wave: This is the most desirable waveform, replicating the smooth, consistent power from a utility grid. It's ideal for sensitive electronics.

- Modified Sine Wave: This is a cruder approximation of a sine wave and is generally suitable for less sensitive appliances, but can cause issues or damage with certain delicate electronics.

- Power Capacity (Wattage): This indicates how much power the device can supply. Ensure it's sufficient to handle the total wattage of the appliances you intend to connect. Exceeding the inverter's capacity can lead to damage.

- Efficiency: A higher efficiency rating means less energy is wasted as heat during the conversion process, which is important for battery-powered setups.

- Safety Features: Look for features like overload protection, short-circuit protection, and surge protection to safeguard your appliances and the inverter itself.

- Frequency: Electrical grids operate at either 50 Hz or 60 Hz. Ensure the inverter's output frequency matches the requirements of your appliances. Some inverters can switch between frequencies.

- Portability: Some are designed for travel, while others are larger for industrial or home use.

- International Travel: They allow travelers from countries with 110V systems (like North America) to use their 220V appliances (like hair dryers, chargers) in countries with 220V outlets (common in Europe, Asia, and other regions).

- Using Imported Appliances: If you have an appliance designed for 220V (e.g., a European kitchen appliance) but your home has 110V outlets, a step-up converter enables you to use it.

- Industrial and Specialized Applications: In industries, they can be used for automation and control systems, telecommunications, and emergency power systems to ensure compatible power supply for various equipment.

- Renewable Energy Systems: In off-grid solar or wind power setups, inverters convert DC power from batteries into the required AC voltage (which could be 110V or 220V depending on the load).

- High-Power Appliances: Some larger appliances or specialized tools might require 220V power, even in regions where 110V is standard for most household items. A converter can provide the necessary voltage without extensive electrical rewiring.