Gate Hardware

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.

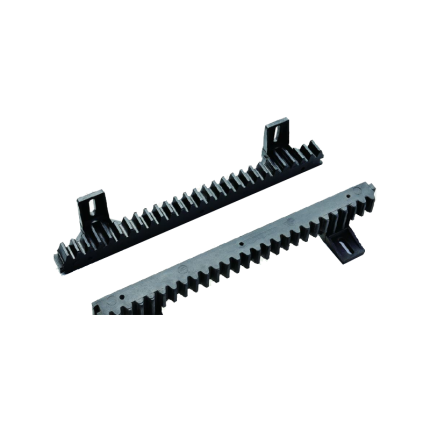

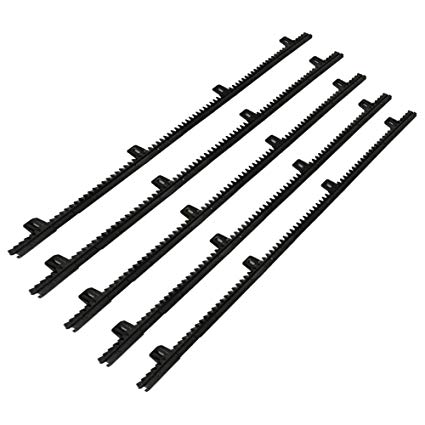

Sliding gate operator gear rack -SLGR2

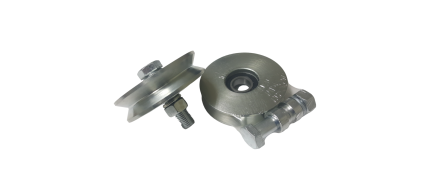

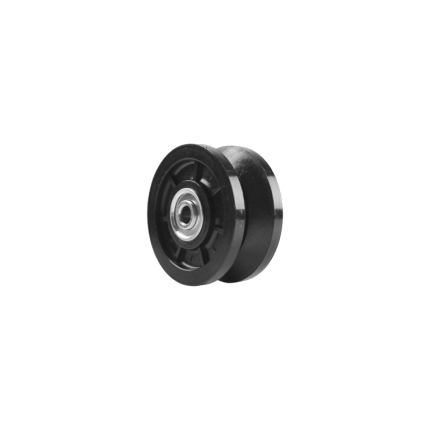

Sliding gate V-Groove nylon wheels -SLGWNS250

Ship or pick up from our office.

*Double bearing *Max 250 Kg *98 mm Diameter (4") x 44 mm Width (1-3/4") (Heavy-duty bolts, nuts, and washers are included)Pedestrian Gate Hinges (Pair)

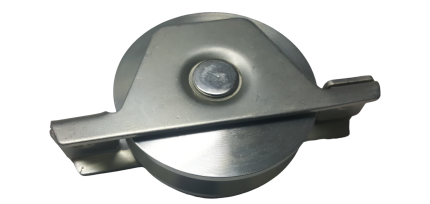

Sliding gate V-Groove wheels – SLGWSS400

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSS400

*Heavy-duty *Steel material *Single bearing *Max 400 Kg *98 mm Diameter x 32 mm Width *Heavy-duty bolts, nuts, and washers are includedSliding gate V-groove wheels are designed to roll along a V-shaped track, providing a guided and stable rolling surface for sliding gates.

These wheels are crucial for the smooth operation of sliding gates, especially those made of metal or used in industrial settings. The V-groove design minimizes friction, reduces noise and vibration, and ensures the gate remains aligned with its track.

Here's a more detailed explanation:

-

Function:V-groove wheels are specifically designed to roll along a V-shaped track, which can be made of angle iron or other suitable materials. This design provides guidance and support for the gate, preventing it from deviating from its intended path.

-

Benefits:The V-groove design offers several advantages:

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

- Noise Reduction: The smooth rolling action reduces noise and vibration compared to other wheel designs.

- Stability: The V-groove ensures the gate remains aligned with the track, preventing it from wobbling or derailing.

- Load Capacity: V-groove wheels are often designed with heavy-duty construction to handle substantial weight, making them suitable for various gate sizes and materials.

- Reduced Friction: The angled surface of the groove allows the wheel to roll smoothly, minimizing friction and making it easier to open and close the gate.

-

Materials:V-groove wheels are available in different materials, including:

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

- Steel: Provides strength and durability, suitable for heavy-duty applications.

- Cast Iron: Another durable option, often used for industrial applications.

- Nylon: Offers good wear resistance, low friction, and resistance to various environmental conditions.

-

Applications:V-groove wheels are used in a wide range of sliding gate applications, including:

- Residential Gates: For driveways and other entryways.

- Commercial Gates: In businesses and industrial settings.

- Industrial Doors: In factories and warehouses.

- Residential Gates: For driveways and other entryways.

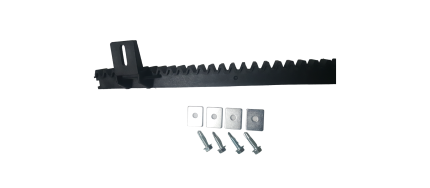

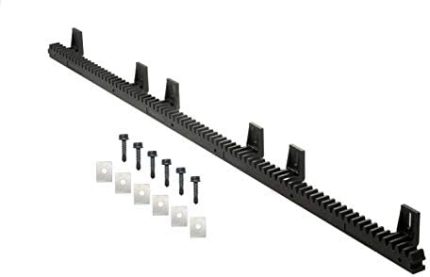

Sliding gate operator gear rack -SLGR41

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR41

*4 Holes *Length: 1018 mmSliding gate V-Groove nylon wheels -SLGWN778MLB

Sliding gate V-Groove wheels – SLGWSD410IB

Ship or pick up from our office.

Sliding gate V-Groove wheels - SLGWSD410IB

*Heavy-duty *Steel material *Double bearing *Interior Bracket *Max 410 Kg *98 mm Diameter x 33 mm WidthA sliding gate V-groove wheel is a type of wheel designed to roll along a V-shaped track, providing support and guidance for sliding gates, particularly those made of metal.

The V-groove in the wheel precisely matches the track, ensuring smooth, stable, and quiet operation. These wheels are often used in industrial and heavy-duty applications due to their ability to handle significant weight and resist wear.

Here's a more detailed explanation:

-

V-Groove Design:The defining feature of these wheels is the V-shaped groove on their circumference. This groove fits snugly onto a corresponding V-shaped track, which can be made of angle iron or other suitable materials.

-

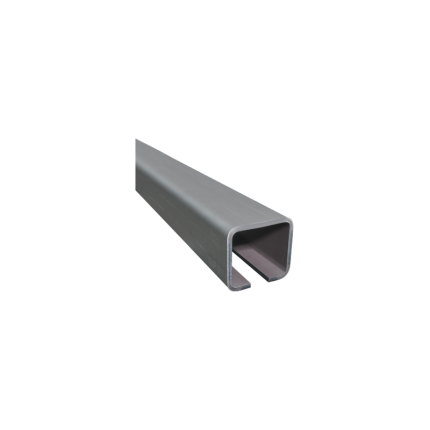

Track System:The track is typically installed along the path where the gate will slide, providing a stable and guided surface for the wheels to roll on.

-

Benefits:V-groove wheels offer several advantages, including:

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

- Stability: The V-groove design provides excellent stability, preventing the gate from wobbling or derailing.

- Durability: Many V-groove wheels are made from durable materials like steel or nylon, offering good wear resistance and longevity.

- Load Capacity: They can handle substantial weight, making them suitable for heavy gates.

- Smooth Operation: The close fit between the wheel and track minimizes friction and vibration, resulting in smooth gate movement.

-

Applications:V-groove wheels are commonly used in:

- Industrial Gates: Supporting heavy doors in factories and warehouses.

- Heavy-Duty Sliding Gates: For residential and commercial properties.

- Automated Gates: Used in conjunction with gate operators.

- Other Sliding Applications: They can also be found in other applications like sliding machinery or even pet gates.

- Industrial Gates: Supporting heavy doors in factories and warehouses.

-

Materials:V-groove wheels can be made from various materials, including:

- Steel: Offers high strength and load capacity.

- Nylon: Provides good wear resistance and reduced noise.

- Polyurethane: Offers a good balance of durability and quiet operation.

- Steel: Offers high strength and load capacity.

-

Installation:The wheels are typically mounted to the bottom of the gate, allowing them to roll along the track.

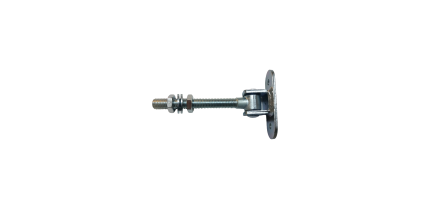

Swing gate adjustable hinge

Ship or pick up from our office.

Swing gate adjustable hinge

*Steel material *Heavy-duty hinge *5-1/2” Length (Total 7-1/2”) x 4-1/2” Width *Bolt thickness: 3⁄4”Support Roller

Ship or pick up from our office.

Support Roller

Support Roller for sliding gates are essential components that ensure smooth, stable, and reliable gate operation.

They guide the gate along its track, preventing it from tipping or falling off and ensuring it opens and closes with minimal friction and noise.

Function:

-

Guidance:Support rollers are typically mounted on the gate posts and guide the gate along its track as it opens and closes.

-

Stability:They keep the gate upright and prevent it from swaying or falling out of alignment, especially in windy conditions or with heavier gates.

-

Smooth Operation:By minimizing friction, they allow the gate to slide easily and quietly, enhancing the user experience.

-

Durability:They are designed to withstand the wear and tear of regular use and exposure to the elements.

Types:

- Nylon Rollers: Often used due to their durability, smooth operation, and resistance to corrosion.

- Rubber Rollers: While cheaper, they may leave marks on the gate and wear out faster.

- V-Groove Wheels: Suitable for specific track types and known for their longevity.

Installation:

- Positioning: Support rollers are typically installed on the gate posts, positioned to guide the gate along its track.

- Spacing: A gap of 5-10mm is usually recommended between rollers to allow for some movement and prevent them from doing all the work, especially if the gate is not perfectly balanced.

- Fixation: They are usually secured with bolts or by welding them to the post.

Maintenance:

-

Lubrication:Applying a silicone-based lubricant to the support rollers and other moving parts can help maintain smooth operation and reduce noise.

-

Regular Inspection:Inspecting rollers for wear and tear or damage is recommended to ensure continued reliable performance.