Gate Hardware

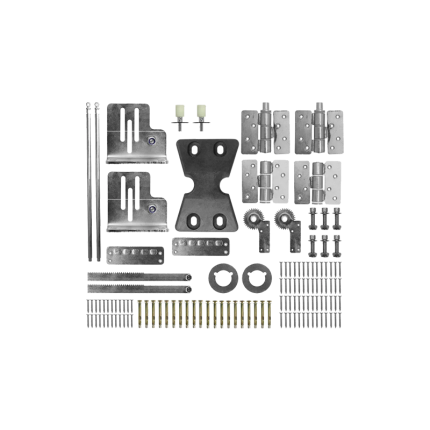

Bi-Folding Gate Hardware

Ship or pick up from our office.

Bi-Folding Gate Hardware

Bi-folding gate hardware refers to the mechanical components and accessories used to construct and operate gates that fold in half when opening, allowing for more efficient use of space.These components include hinges, rollers, pivots, guides, and other necessary parts that enable the gate to fold and unfold smoothly.

Key Components and Features:

-

Hinges:These are crucial for the folding action, connecting the gate leaves and allowing them to pivot.

-

Rollers and Guides:These components ensure smooth and stable movement of the gate along a track or within a frame.

-

Drop Bolts:These secure the gate in the open or closed position, providing stability and preventing unwanted movement.

-

Handles:These are used to manually operate the gate.

-

Specialized Mechanisms:Some systems utilize geared hinges or other mechanisms to ensure smooth and reliable operation, especially for larger gates.

Benefits of Bi-folding Gates:

-

Space Saving:Bi-folding gates require less space to open compared to traditional swinging gates, making them ideal for areas with limited space.

-

Versatility:They can be used with gate automation systems and are suitable for various gate sizes and configurations.

-

Enhanced Accessibility:Bi-folding gates provide easy access to enclosed spaces without obstructing parking or other areas.

-

Improved Aesthetics:They can be designed with various styles and finishes to complement the overall aesthetic of the property.

-

Cost-Effective:Bi-folding gates can be more cost-effective to automate than traditional double swing gates as they require fewer operators.

Applications:

- Residential driveways where space is limited.

- Commercial and industrial properties requiring secure access.

- Areas with challenging terrain, such as those with gravel surfaces.

- Condominiums and other multi-unit dwellings.

Cantilever Sliding Gate Hardware

Ship or pick up from our office.

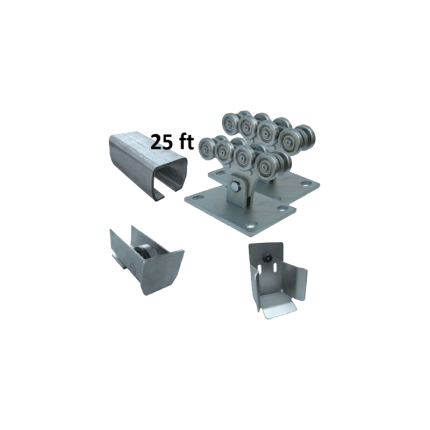

Cantilever Sliding Gate Hardware

Cantilever sliding gate hardware refers to the specialized components that allow a gate to slide open and close without needing a track on the ground. Instead, the gate is supported and guided from above and to the side by a system of rollers and channels. Here's a breakdown of the essential components that make up cantilever sliding gate hardware:- Cantilever Track (or Rail):

- This is the most distinctive part. It's a heavy-duty, usually C-shaped (or sometimes a more complex extruded profile) channel that's securely attached to the bottom (or sometimes top) of the gate frame itself.

- The track is extended beyond the main gate opening to form the "tail" or counterbalance section, which supports the gate when it's fully open.

- Materials: Commonly made from galvanized steel for strength and corrosion resistance, or aluminum for lighter weight and superior corrosion resistance (as discussed previously).

- Cantilever Carriages (or Trolleys/Rollers):

- These are the critical load-bearing components. They consist of a sturdy base plate with multiple wheels (often 5, 8, or more) arranged in a specific configuration.

- The wheels are made from durable materials like steel (often machined or cast) or high-impact nylon, and typically feature sealed bearings for smooth, maintenance-free operation.

- The cantilever track fits over these carriages, with the wheels rolling inside the track's channel.

- Two (or more for very long/heavy gates) carriages are typically mounted on strong concrete foundation posts, positioned outside the gate opening. These posts support the entire weight of the gate.

- Guide Rollers/Plates (Upper Guides):

- These are smaller rollers or plates mounted on a separate guide post (or posts) on the same side as the cantilever carriages.

- Their purpose is to keep the gate upright and prevent it from tipping over as it moves. They typically engage with the top rail of the gate.

- Made from nylon, steel, or a combination, often with adjustable brackets.

- End Cups / Receiver Posts / Gate Catches:

- End Cup (or End Stop): A cup or bracket mounted on the support posts at the fully closed position. The end of the gate's tail section (specifically the track) "rests" in this cup when the gate is fully closed, providing additional stability and support.

- Receiver Post / Gate Catch: A post or latching mechanism at the opposite end of the gate opening. When the gate is fully closed, it engages with this post to secure the gate in the closed position. This is often where a lock or the gate operator's arm connects.

- Support Wheels / Final Wheels: Sometimes, a small support wheel is mounted on the ground or a low post at the far end of the gate opening to provide extra support to the gate's leading edge when it's fully closed, especially for very long or heavy gates.

- Anchoring and Installation Accessories:

- Foundation Plates/Anchor Bolts: Heavy-duty plates and bolts used to securely anchor the cantilever carriages to concrete foundations. The stability of the entire system relies on robust anchoring.

- Tension Bars (less common in modern designs): Historically used for minor adjustments to gate alignment or sag, though modern systems are often designed to minimize this need.

- No Ground Track: This is the primary advantage. Eliminates the need for a track embedded in the driveway, which means:

- No debris accumulation (leaves, dirt, snow, ice) obstructing movement.

- Smoother operation on uneven driveways.

- Less maintenance in terms of track cleaning.

- No tripping hazard or wear on vehicles crossing a ground track.

- Durability and Low Maintenance: Because the main rolling components (carriages) are elevated and enclosed within the track, they are less exposed to dirt and weather, leading to longer life and less frequent maintenance.

- High Security: Cantilever gates are inherently very secure as they are difficult to lift or derail.

- Aesthetics: The absence of a ground track can contribute to a cleaner, more streamlined look for the driveway entrance.

- Suitable for High-Traffic Areas: Their robust design makes them ideal for commercial, industrial, or busy residential applications.

- Gate Automation and Supply Companies: Businesses specializing in automatic gates will carry a full range of cantilever hardware. Examples include Royal Gates (Royal Electronic Technology Center Co.), presence in the Metro Vancouver area, including Surrey.

- Fencing and Gate Fabricators: Many companies that custom-fabricate gates will also supply or install the necessary hardware.

- Industrial Hardware Suppliers: Larger industrial suppliers may stock components, though specialized gate companies will offer more comprehensive systems.

- Online Retailers: Many online suppliers ship to Canada, offering a wide variety of components from different manufacturers.

Cantilever sliding gate track

Ship or pick up from our office.

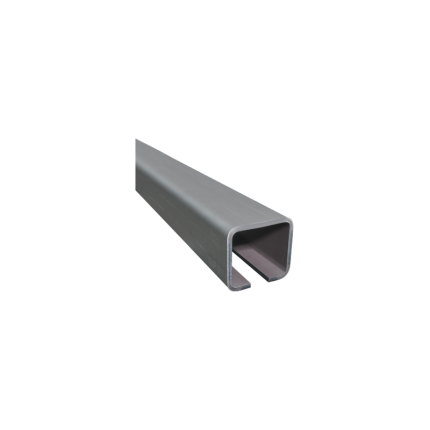

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

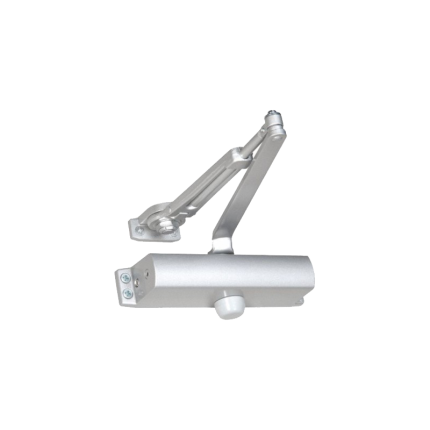

Door closer -DCL061

Door closer -DCL062

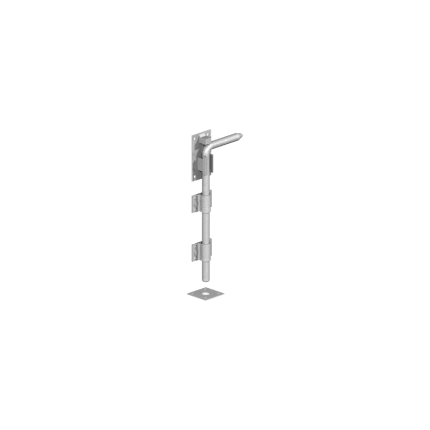

Gate drop ground latch

Ship or pick up from our office.

Gate drop ground latch

A gate drop ground latch, also known as a cane bolt or drop rod, is a hardware mechanism used to secure a gate in either the open or closed position by inserting a rod into the ground.

It's commonly used for single or double gates, including wooden fences, metal gates, and even barn doors, to provide extra stability and prevent unwanted movement.

Here's a more detailed explanation:

How it works:

- The latch typically consists of a rod (the "drop rod" or "cane bolt") and a bracket or receiver that is mounted on the gate.

- When the gate is in the desired position (open or closed), the rod is manually lowered through the bracket and into a hole or receiver in the ground.

- This creates a secure hold, preventing the gate from swinging or being moved by wind or other forces.

- Some designs include a bracket or keeper to hold the rod in the raised (open) position when not in use.

Common uses:

- Securing single or double gates: The drop ground latch can be used on both types of gates to keep them firmly in place.

- Providing stability in windy conditions: It helps prevent gates from being blown open or closed by the wind.

- Securing gates in the open position: It can be used to hold a gate open, preventing it from accidentally closing.

- Reinforcing gate security: It adds an extra layer of security, making it more difficult to force the gate open.

- Suitable for various materials: Can be used with wood, metal, and other gate materials.

Benefits:

- Enhanced security: Prevents gates from being moved by wind or other forces.

- Increased stability: Helps keep gates aligned and prevents sagging.

- Versatile application: Can be used on a variety of gates and in different environments.

- Easy to operate: Simple manual operation to engage and disengage the latch.

- Relatively easy to install: Usually requires drilling holes for mounting the brackets.

Gate drop ground latch

Ship or pick up from our office.

Gate drop ground latch

A gate drop ground latch, also known as a cane bolt or drop rod, is a mechanism used to secure a gate in the open or closed position by inserting a rod into the ground.

It's typically used for double gates to keep one side stationary while the other is latched. It helps prevent gates from moving in the wind and adds extra security.

Here's a more detailed explanation:

How it works:

- A metal rod (the drop rod or cane bolt) is attached to the gate and slides through brackets or guides.

- When the gate is in the desired position (open or closed), the rod is lowered into a hole or receiver in the ground, securing the gate.

- To open the gate, the rod is lifted out of the ground and turned out of the way.

Key features and benefits:

- Secures gates: Prevents gates from swinging open or closed due to wind or other factors.

- Versatile: Can be used on various gate types, including wood, metal, and vinyl.

- Double gate support: Especially useful for securing one side of a double gate while the other is latched.

- Added security: Can be used in conjunction with other latches for increased security.

- Easy installation: Generally involves mounting brackets and drilling a hole for the rod.

- Durable: Made of materials like steel, often with a powder coat finish for weather resistance.

Gate Rubber Stopper A1

Ship or pick up from our office.

Gate Rubber Stopper A1

Types of Rubber Stoppers:

- Fixed rubber stoppers: Permanently installed, often used for heavier gates.

- Adjustable rubber stoppers: Allow for customization of the gate's swing position.

- Spring-loaded rubber stoppers: Combine a spring mechanism with the rubber for enhanced shock absorption and noise reduction.

- Floor-mounted rubber stoppers: Attached to the floor to stop the gate's movement.

Where they are used:

-

Swing gates:Commonly used to prevent swing gates from hitting walls, posts, or other structures.

-

Sliding gates:Used to stop the gate at the end of its track, preventing it from rolling off.

-

Industrial gates:Used in various industrial settings for gates that experience frequent and forceful use.

-

Residential gates:Used in homes to protect gates, walls, and prevent accidents.

Pedestrian Gate Hinges

Ship or pick up from our office.

Pedestrian Gate Hinges

Pedestrian gate hinges are designed to allow a gate intended for pedestrian use to swing open and closed, connecting the gate to its post or frame.

These hinges are crucial for the smooth operation and secure closure of the gate, ensuring proper alignment and functionality. They can be surface-mounted, bolt-on, or weld-on, and may include features like spring-assist or adjustable tension for self-closing.

Here's a more detailed breakdown:

-

Function:Pedestrian gate hinges primarily serve to join the gate to its supporting structure (post or frame) and allow for rotation.

-

Types:They can be surface-mounted, bolt-on, or weld-on, offering different installation methods.

-

Features:Some hinges incorporate self-closing mechanisms, like spring-assist or adjustable tension, which can be important for safety or convenience.

-

Materials:They are commonly made from steel, stainless steel, or polymer, ensuring durability and resistance to the elements.

-

Applications:Pedestrian gate hinges are suitable for various settings, including residential, HOA, and commercial properties, especially for side gates, walkways, and restricted access enclosures.

-

Considerations:When choosing hinges, factors like the gate's weight, size, and desired functionality (e.g., self-closing) should be taken into account.