Accessories

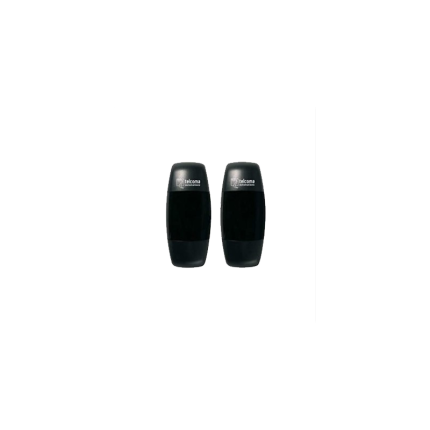

Safety sensor P51022H

Ship or pick up from our office.

Safety sensor P51022H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *Internal Rotation system: 0~180Safety Sensor P52000H

Ship or pick up from our office.

Safety Sensor P52000H

IP Rating: IP54

Certification: CE

Working Voltage: 12V-24V AC/DC

Temperature Rane: -20ºC to 60 ºC

Protection Index: IP54

Photocell Wavelength: 940nm

Receiver Range: More Than 12m

Weight: 139g

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

Safety Sensor S300

Ship or pick up from our office.

Safety Sensor S300

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

Safety sensor VDS-TEC2

Ship or pick up from our office.

Safety sensor VDS-TEC2

Technical Details:- NO/NC

- AC/DC 12-24 V

- Receiving Range: 15 Meters

- IP 44

- Compact

- Lightweight

- Portable

- Easy to use

Safety sensor VEDO180

Ship or pick up from our office.

Safety sensor VEDO180

*NO/NC *AC/DC 12-24 V *Receiving Range: 25 Meters *IP 44Sliding gate operator limit sensor – Magnetic mechanism

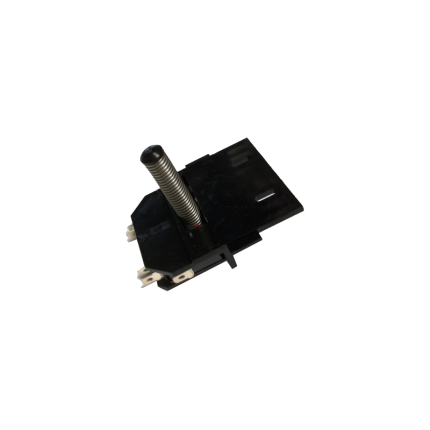

Ship or pick up from our office.

Sliding gate operator limit sensor - Magnetic mechanism

A sliding gate operator limit sensor, often a limit switch, is a crucial component that signals the gate operator when the gate has reached its fully open or fully closed position, stopping the motor and preventing over-travel. These sensors ensure the gate stops at the correct positions, preventing damage to the gate and surrounding structure.

Here's a more detailed explanation:

-

Function:Limit sensors, like limit switches, detect when the gate reaches its extreme open or closed positions.

-

How it works:When the gate reaches the limit, the sensor sends a signal to the gate operator's control board, which then stops the motor.

-

Importance:Without limit sensors, the gate might continue to move, potentially hitting the end posts or other obstructions, causing damage.

-

Types:Common types include magnetic limit switches and photoelectric sensors (photo eyes).

-

Magnetic Limit Switches:These utilize magnets placed on the gate and a magnetic sensor on the operator. When the magnet aligns with the sensor, it triggers the limit switch.

-

Photoelectric Sensors (Photo Eyes):These use infrared beams to detect obstructions. When the beam is broken (e.g., by the gate), the sensor signals the operator to stop.

-

Installation:Proper installation and adjustment of limit sensors are crucial for the reliable operation.

-

Maintenance:Regular inspection and maintenance of limit sensors are recommended, as they can wear out or become misaligned over time.

Sliding gate operator limit sensor – Spring mechanism

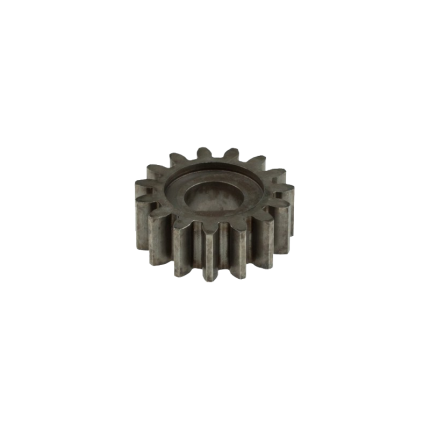

Sliding gate operator’s gear

Sliding gate operator’s gear

Sliding gate operator’s limit sensor – Spring mechanism

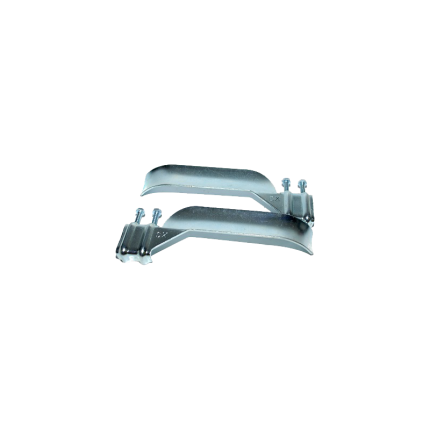

Sliding gate operator’s limit stopper brackets

Ship or pick up from our office.

Sliding gate operator’s limit stopper brackets

The gate operator system with a damaged limit stopper bracket can not work properly, and it will soon stop working. Most of the time, the main control board and the motor will be damaged because of this issue and have to be replaced. Sometimes errors come from the limit stopper bracket not working because they are damaged and they need only to be cleaned or readjustment.A sliding gate operator limit stopper bracket is a component that works with limit switches to prevent a sliding gate from over-extending its travel, ensuring it stops at the desired open and closed positions.

These brackets typically hold magnets or other sensor components that interact with the limit switches on the gate operator's control board. They help maintain the gate's smooth and safe operation by preventing it from hitting obstructions or going off its track.

Here's a more detailed explanation:

-

Purpose:The primary function of the limit stopper bracket is to define the boundaries of the gate's movement. It ensures the gate stops at the fully open and fully closed positions, preventing it from over-traveling.

-

How it works:The bracket holds a magnetic or other type of sensor that is triggered when the gate reaches its limit. This trigger sends a signal to the gate operator's control board, which then stops the motor.

-

Components:

- Bracket: The physical structure that holds the sensor.

- Sensor: A device (often a magnet) that interacts with the limit switch.

- Limit Switch: A switch on the gate operator's control board that is activated by the sensor.

- Bracket: The physical structure that holds the sensor.

-

Importance:

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.

- Reliability: Ensures consistent and reliable gate operation by defining the travel limits.

- Protection: Protects the gate, operator, and surrounding objects from damage due to over-travel.

- Safety: Prevents the gate from hitting objects or going off track, reducing the risk of damage or injury.