Accessories

Radio receiver RX2CH-Multi Code

Gate operator capacitor

Ship or pick up from our office.

Gate operator capacitor

A gate operator capacitor is an electrical component that assists the motor in a gate opener system to start and run smoothly.

It stores and releases electrical energy to provide the initial torque needed to get the motor going and to ensure consistent operation. These capacitors are crucial for both swing and sliding gate openers that are powered by AC.

Here's a more detailed explanation:

-

Starting the Motor:When a gate opener is activated, the motor needs a significant amount of power to begin rotating. The capacitor provides a burst of electrical energy to help the motor overcome its inertia and start moving.

-

Maintaining Smooth Operation:Once the motor is running, the capacitor helps to smooth out the electrical current, ensuring consistent and efficient operation. This prevents the motor from stalling or experiencing performance issues due to voltage fluctuations.

-

Types of Capacitors:Gate operator capacitors can be categorized as either start capacitors or run capacitors.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

- Run capacitors: help to maintain consistent motor performance during operation.

- Start capacitors: are used to provide the initial surge of power needed to get the motor rotating.

-

Common Applications:Capacitors are used in various gate operator systems, including:

- Swing gate openers

- Sliding gate openers

- Commercial and residential gate systems

- Barrier arms

- Overhead doors

- Swing gate openers

-

Compatibility:Different gate operators may require specific types and sizes of capacitors, so it's important to choose the right replacement capacitor for your system.

Safety Sensor P52000H

Ship or pick up from our office.

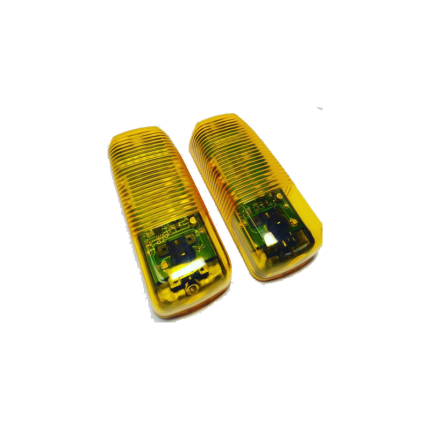

Safety Sensor P52000H

IP Rating: IP54

Certification: CE

Working Voltage: 12V-24V AC/DC

Temperature Rane: -20ºC to 60 ºC

Protection Index: IP54

Photocell Wavelength: 940nm

Receiver Range: More Than 12m

Weight: 139g

A gate opener safety sensor is a crucial component of automated gate systems designed to prevent accidents and damage by detecting obstructions in the gate's path.

These sensors, often photoelectric, use an infrared beam to monitor the area and trigger the gate to stop or reverse if something is blocking its movement.

How it works:

-

Transmitter and Receiver:A safety sensor typically consists of a transmitter that emits an infrared light beam and a receiver that detects the beam.

-

Obstruction Detection:When an object, person, or vehicle interrupts the beam, the receiver signals the gate operator to stop or reverse the gate's movement.

-

Safety Feature:This mechanism prevents the gate from closing on anything or anyone, ensuring safety and preventing potential damage.

Types of Safety Sensors:

-

Photoelectric Sensors (Photo Eyes):These are the most common type, using an infrared beam to detect obstructions.

-

Safety Edges:These sensors are typically placed along the edge of the gate and trigger a stop or reverse when they encounter pressure.

-

Induction Loops:These sensors are embedded in the ground and detect vehicles as they pass over them, triggering the gate to open or close.

Importance:

-

Safety:The primary function is to prevent accidents and injuries by stopping or reversing the gate when an obstruction is present.

-

Preventing Damage:By detecting obstructions, these sensors help avoid damage to the gate, vehicles, or anything else in its path.

-

Compliance:Safety sensors are often required for automated gates to meet safety regulations and standards.

Common Issues:

-

Misalignment:If the sensor is misaligned, the infrared beam may not reach the receiver, causing the gate to malfunction.

-

Obstructions:Debris, dirt, or other obstructions can interfere with the beam and trigger false alarms.

-

Sensor Failure:Like any electronic device, sensors can fail over time, requiring replacement.

Door Strike Lock

Ship or pick up from our office.

Door Strike Lock

An electric strike is an electromechanical lock release device that replaces a standard door strike plate.

It allows a door to be opened remotely, typically via an access control system, without manually retracting the latch. When activated, the electric strike releases the latch, enabling the door to be opened.

Here's a more detailed explanation:

Functionality:

-

Replaces Standard Strike:Electric strikes are installed in the door frame, taking the place of the standard strike plate.

-

Remote Release:They are designed to work with various access control systems, such as keypads, card readers, or intercoms.

-

Activation:When an authorized signal is received (e.g., a code is entered, a card is swiped), the electric strike releases the latch, allowing the door to be opened.

-

Fail-Safe or Fail-Secure:Electric strikes can be configured in either a fail-safe or fail-secure mode.

- Fail-safe: In this mode, the door unlocks when power is lost, making it suitable for safety applications where access is needed during power outages.

- Fail-secure: In this mode, the door remains locked when power is lost, requiring power to unlock, making it suitable for high-security applications.

- Fail-safe: In this mode, the door unlocks when power is lost, making it suitable for safety applications where access is needed during power outages.

How it Works:

- The electric strike contains a solenoid, which is an electromagnet.

- When the solenoid is activated by an electrical signal, it moves a component (like an armature) that allows the latch to move freely.

- This movement releases the door, allowing it to be opened.

Key Differences from Other Locks:

-

Electric vs. Magnetic Locks:Unlike magnetic locks, which use powerful magnets to hold the door closed, electric strikes release the latch mechanism.

-

Remote Access:Electric strikes offer remote access control, allowing doors to be unlocked without manual intervention.

-

Versatility:They can be used with various locking mechanisms, including cylindrical, mortise, and rim exit devices.

Common Applications:

-

Access Control:Electric strikes are a core component of access control systems in commercial and residential settings.

-

Security:They provide a higher level of security compared to standard locks, especially when used with fail-secure configurations.

-

Safety:In fail-safe configurations, they ensure safe egress during emergencies.

-

Specific Areas:They are commonly found in reception areas, daycare centers, and other locations where controlled access is needed.

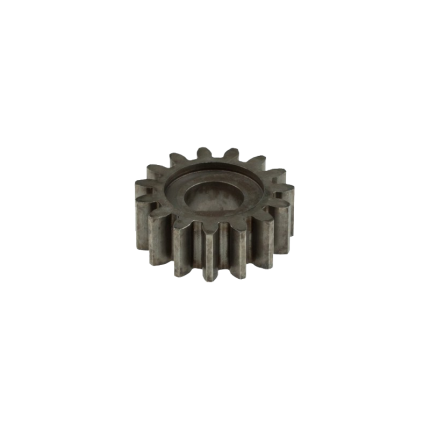

Sliding gate operator’s gear

Safety sensor – P51033H

Ship or pick up from our office.

Safety sensor - P51033H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *The safety sensor included the LED flash lightUniversal sliding gate operator control board SLRG24

Ship or pick up from our office.

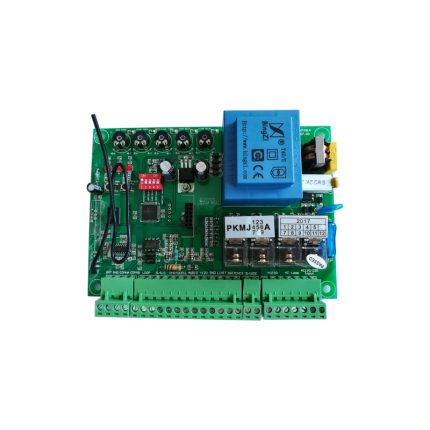

Universal sliding gate operator control board SLRG24

The Universal Sliding Gate Operator Control Board SLRG24 is the "brain" of an automatic sliding gate system. It's designed to be a versatile replacement or core component for various DC-powered sliding gate operators, meaning it can control a wide range of motors and integrate with different accessories. Here's a detailed look at its features and significance: Core Function of a Control Board: The control board is the central electronic unit that:- Receives Signals: Interprets commands from remote controls, keypads, safety sensors (photocells, shock sensors, loop detectors), intercom systems, and other access control devices.

- Processes Logic: Decides what action the gate should take based on the received signals and its programmed settings (e.g., open fully, partially open for pedestrian, close, stop, reverse due to obstruction).

- Activates Motor: Sends the appropriate electrical signals to the gate motor to start, stop, or reverse its movement.

- Manages Accessories: Controls the power and operation of connected safety and convenience accessories like flashing lights, electric locks, and alarm outputs.

- Universal Compatibility: This is its defining characteristic.

- DC Motor Compatibility: It's designed to work with both DC 12V and DC 24V motors. This flexibility is crucial as many sliding gate operators use one of these DC voltages. It's important to note that it is NOT compatible with AC (Alternating Current) motors (like 110V or 220V AC motors).

- Limit Switch Flexibility: It can work with both spring-type mechanical limit switches and magnetic limit switches. This is a significant advantage for a universal board, as it means it can be used with a wider range of existing gate operators.

- Input Power: The board itself typically requires an AC 24V input power. This means it likely has an internal transformer or is designed to be powered by an external AC 24V transformer.

- Full Programmability: Offers a wide range of adjustable parameters, allowing customization of gate operation to suit specific needs:

- Gate Speed: Adjustment of how fast the gate opens and closes.

- Opening/Closing Times: Setting precise durations for gate cycles.

- Automatic Closing Time: Programming a delay before the gate automatically closes after opening (e.g., 15, 30, 45 seconds, or up to 3 minutes).

- Safety Settings: Integration and management of safety sensors (photocells, obstacle detection sensitivity).

- Pedestrian Mode: Ability to set a partial opening for pedestrian access.

- Party Mode: Often allows for temporary cancellation of auto-close for periods when many visitors are expected.

- Remote Control Capability:

- Features an integrated radio receiver, typically operating at 433.92MHz with rolling code technology. Rolling code prevents unauthorized cloning of remote controls, enhancing security.

- Supports multiple remote controls (e.g., up to 20 or more), making it suitable for larger families or multi-user environments.

- Accessory Output Power: Provides DC 24V accessory output power (e.g., 200mA max) to power various external devices:

- Safety Sensors (Photocells): Connects to and powers safety beams.

- Warning Flash Lights: Powers a flashing beacon that activates when the gate is in motion.

- Keypads/Intercom Systems: Provides power and input connections for wired access control devices.

- Electric Locks: Can manage the operation of an electric lock for added security.

- Safety Mechanisms:

- Obstacle Detection: Uses current sensing or other methods to detect if the gate encounters an obstruction during movement. Upon detection, it will typically stop or reverse the gate for safety.

- Automatic Stop Function: Ensures the gate stops precisely at its programmed limits.

- Short Circuit Protection: Often includes protection for output circuits (e.g., lock output) to prevent damage from wiring faults.

- Solar System Input: The mention of "Input Solar system" suggests it's designed to be compatible with or directly connect to solar charging systems for off-grid gate installations, making it suitable for rural properties or areas without easy access to AC power.

- Installation and Durability:

- Designed for relatively easy installation.

- Built with robust components for long-lasting performance in various weather conditions, though it usually requires housing in a waterproof box (often included in a kit).

- Features an automatic power-off memory function, retaining settings after a power outage.

- Replacing a Faulty Board: If an existing 12V or 24V DC sliding gate operator has a non-functional control board, the SLRG24 could be a suitable and cost-effective replacement, reducing the need to replace the entire gate motor.

- New Custom Gate Systems: It provides a flexible "brain" for custom-built sliding gate systems where the motor and other components are chosen separately.

- Solar-Powered Gates: Its solar input capability is a definite advantage for properties in Surrey or surrounding areas that might prefer or require solar power for their gate.

Safety sensor P51022H

Ship or pick up from our office.

Safety sensor P51022H

*NO/NC *AC/DC 12-24 V *Receiving Range: 12 Meters *IP 54 *External LED flash lamp signal (AC/DC 12V-24 V) *Internal Rotation system: 0~180Garden LED Light -Key Automation STIKFD

Ship or pick up from our office.

Garden LED Light -Key Automation STIKFD

PRODUCT SHEET PDF *Step lights, garage doors, and pergola lights *Completely made of aluminum *Power: 24-35 V/DC - 2W *Body color: Grey *LED color: 4400K/132lm *Length: 240 mm *Version: Flat *International Protection Rating: IP 54Sliding gate operators limit sensor -Spring

Ship or pick up from our office.

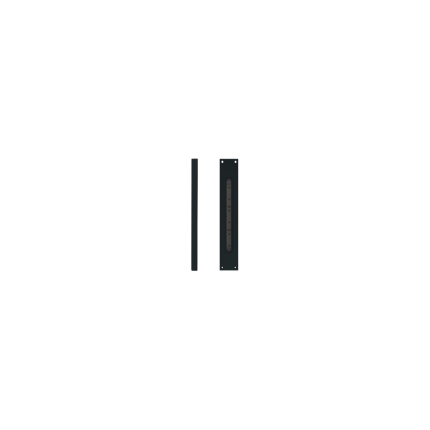

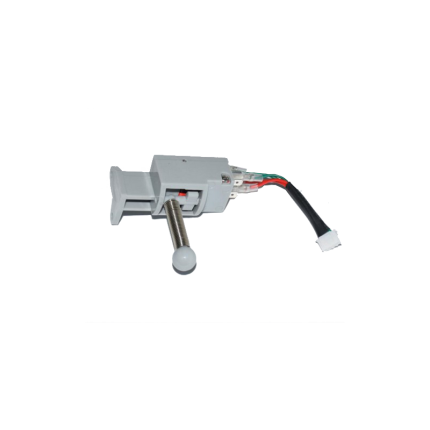

Sliding gate operator limit sensor -Spring

A sliding gate operator limit sensor with a spring mechanism (also known as a mechanical limit switch or spring limit switch) is a common type of sensor used in automatic sliding gate systems to define the gate's fully open and fully closed positions. Here's how it works and what its characteristics are: Purpose of a Limit Sensor: For any automatic gate operator, the system needs to know exactly when the gate has reached its desired open and closed positions. This is crucial for:- Stopping the Motor: Preventing the motor from continuing to run once the gate has reached its limit, which would otherwise cause damage to the gate, the motor, or the track.

- Safety: Ensuring the gate stops precisely where it should, preventing it from hitting obstacles or over-extending.

- Proper Operation: Allowing for features like auto-closing, pedestrian mode, and proper synchronization if it's a dual-gate system.

- Components: A spring limit switch typically consists of:

- A microswitch (an electrical switch that requires very little force to operate).

- A spring-loaded lever, arm, or plunger connected to the microswitch.

- A mounting bracket to attach it to the gate operator or gate frame.

- Mounting: The spring limit switch is usually positioned on the gate operator itself, or on a bracket near the motor.

- Interaction with the Gate:

- On the sliding gate itself, usually along the gear rack or a specific part of the gate frame, two small "stop" tabs or flags are installed – one for the open limit and one for the close limit.

- As the gate moves towards its fully open or fully closed position, one of these tabs/flags will physically contact and push against the spring-loaded lever/plunger of the limit switch.

- This physical contact compresses the spring and activates the microswitch.

- Signal to Control Board: When the microswitch is activated, it sends an electrical signal to the gate operator's main control board.

- Motor Stop: Upon receiving this signal, the control board immediately cuts power to the motor, stopping the gate precisely at that determined limit.

- Physical Contact: The defining feature is that it relies on direct physical contact and force to activate the switch.

- Reliability: Generally reliable as they are a simple mechanical system.

- Durability: Made to withstand repeated physical contact. However, over time, the spring can wear out, lose tension, or the switch itself can be damaged by repeated impacts or debris.

- Adjustability: The position of the "stop" tabs on the gate can be adjusted to fine-tune the exact open and closed positions of the gate.

- Maintenance: May require periodic checks to ensure the spring is intact, the switch is clean, and the "stop" tabs are securely in place and correctly positioned. They can be susceptible to damage from impacts (e.g., if a child's toy or a pet gets in the way of the stop tab).

- Compared to Magnetic Limit Switches:

- Magnetic Limit Switches: These are more common in newer and higher-end gate operators (like many BFT Deimos "Ultra" models). They use magnets attached to the gate and magnetic sensors (reed switches or Hall effect sensors) on the operator. They offer a "contactless" operation, which generally leads to less wear and tear, greater precision, and less susceptibility to environmental debris or physical impact damage.

- Spring/Mechanical Limit Switches: Are typically more cost-effective and simpler in design. They are still widely used, especially in more budget-friendly or older gate operator models.