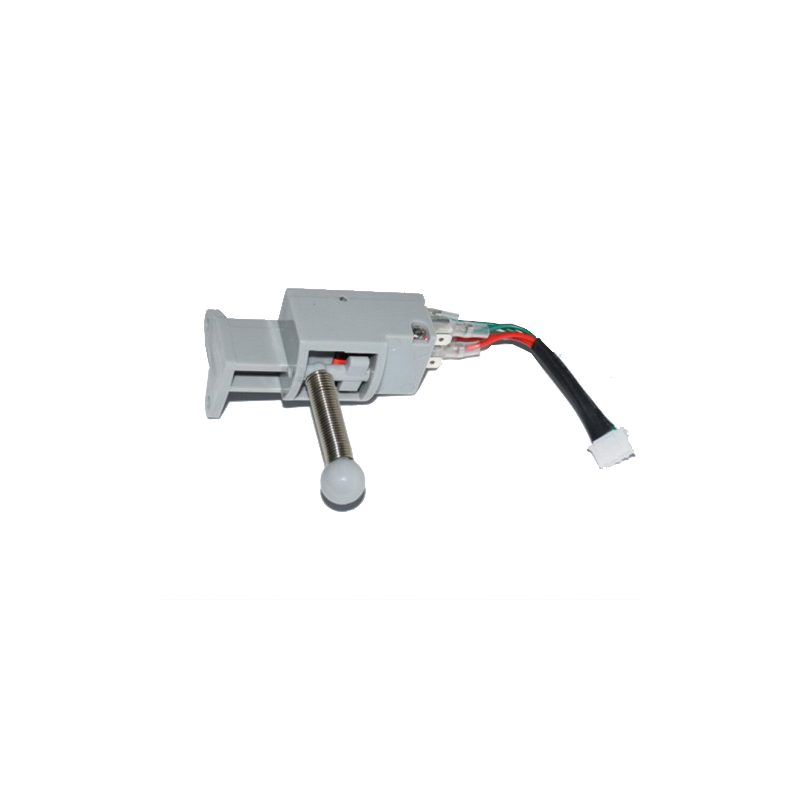

Sliding gate operators limit sensor -Spring

A sliding gate operator’s spring limit mechanism uses a spring-loaded switch to control the gate’s movement. When the gate reaches its fully open or closed position, the spring is compressed, triggering the switch to cut power to the motor and stop the gate’s movement. This mechanism relies on physical contact and force exerted by the gate on the spring, unlike magnetic limit switches, which use magnets and sensors.

-

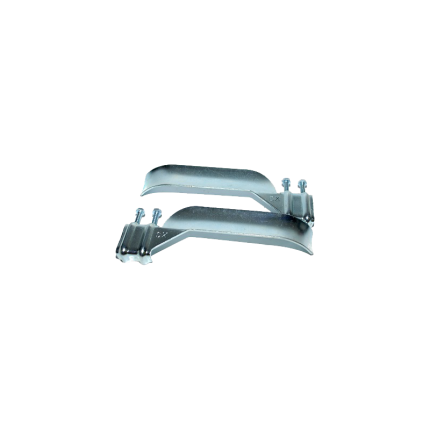

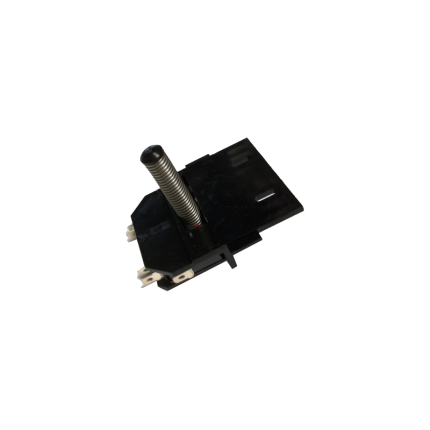

Spring and Switch:

The system includes a spring and a limit switch. The spring is typically mounted on a bracket or lever.

-

Gate Contact:

As the gate moves, it pushes against the spring, compressing it.

-

Switch Activation:

Once the gate reaches its limit (fully open or closed), the compressed spring activates the limit switch.

-

Motor Stop:

The activated switch sends a signal to the gate operator’s control board, which then stops the motor.

- Physical Mechanism: The spring mechanism is a physical, contact-based system.

- Reliability: It provides a reliable way to define the gate’s travel limits.

- Maintenance: Regular checks are needed to ensure the spring and switch are functioning correctly.

- Simplicity: The spring mechanism is relatively simple and easy to understand.

- Cost-Effective: It can be a more affordable option compared to some other limit switch systems.

-

Durability:

The spring and switch mechanism can be more susceptible to wear and tear over time compared to magnetic systems.

-

Sensitivity:

It can be more sensitive to impacts or obstructions, potentially leading to damage or misalignment.

-

Maintenance:

It may require more frequent adjustments or replacements compared to magnetic systems.

-

Magnetic Limit Switches:Use magnets and reed switches to detect gate position, offering greater reliability and smoother operation.

-

Spring Limit Switches:Rely on physical contact and force, which can be more prone to wear and tear.

Reviews

There are no reviews yet.