Ship or pick up from our office.

Cantilever Sliding Gate Hardware

Cantilever sliding gate hardware refers to the specialized components that allow a gate to slide open and close without needing a track on the ground. Instead, the gate is supported and guided from above and to the side by a system of rollers and channels.

Here's a breakdown of the essential components that make up cantilever sliding gate hardware:

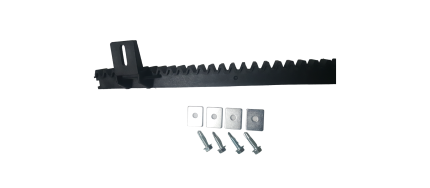

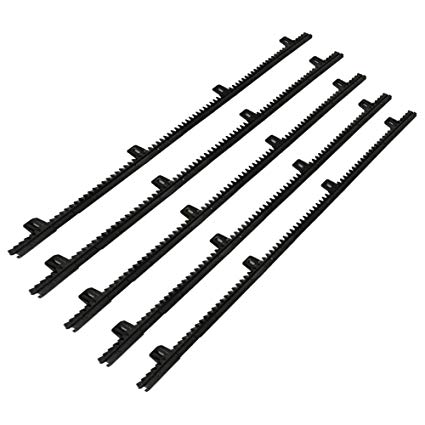

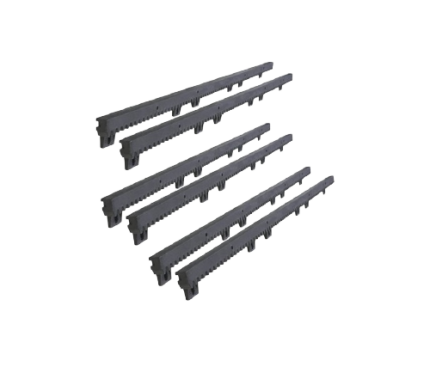

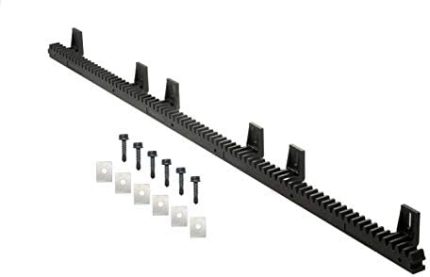

- Cantilever Track (or Rail):

- This is the most distinctive part. It's a heavy-duty, usually C-shaped (or sometimes a more complex extruded profile) channel that's securely attached to the bottom (or sometimes top) of the gate frame itself.

- The track is extended beyond the main gate opening to form the "tail" or counterbalance section, which supports the gate when it's fully open.

- Materials: Commonly made from galvanized steel for strength and corrosion resistance, or aluminum for lighter weight and superior corrosion resistance (as discussed previously).

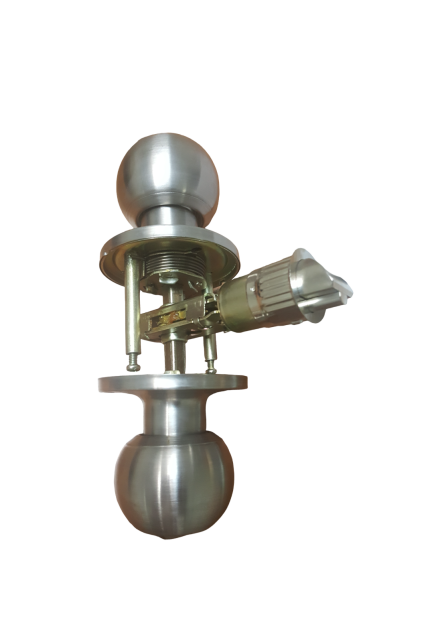

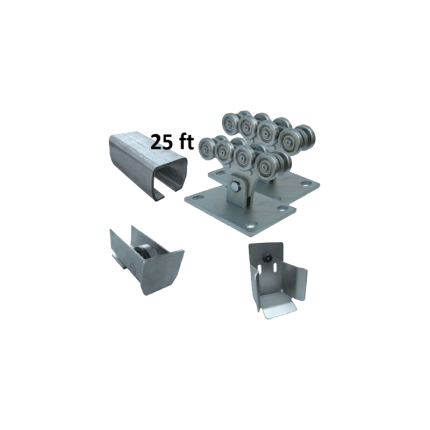

- Cantilever Carriages (or Trolleys/Rollers):

- These are the critical load-bearing components. They consist of a sturdy base plate with multiple wheels (often 5, 8, or more) arranged in a specific configuration.

- The wheels are made from durable materials like steel (often machined or cast) or high-impact nylon, and typically feature sealed bearings for smooth, maintenance-free operation.

- The cantilever track fits over these carriages, with the wheels rolling inside the track's channel.

- Two (or more for very long/heavy gates) carriages are typically mounted on strong concrete foundation posts, positioned outside the gate opening. These posts support the entire weight of the gate.

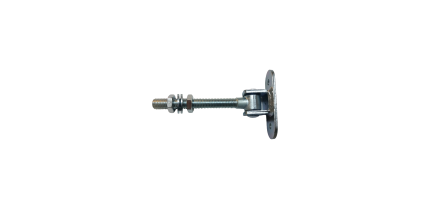

- Guide Rollers/Plates (Upper Guides):

- These are smaller rollers or plates mounted on a separate guide post (or posts) on the same side as the cantilever carriages.

- Their purpose is to keep the gate upright and prevent it from tipping over as it moves. They typically engage with the top rail of the gate.

- Made from nylon, steel, or a combination, often with adjustable brackets.

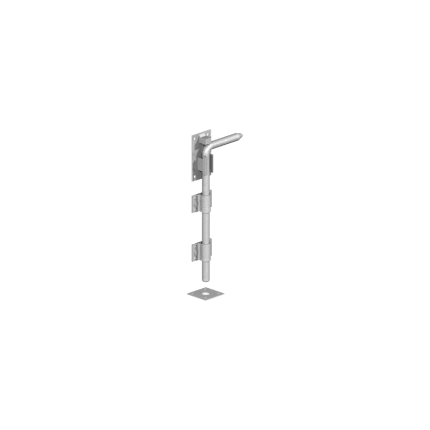

- End Cups / Receiver Posts / Gate Catches:

- End Cup (or End Stop): A cup or bracket mounted on the support posts at the fully closed position. The end of the gate's tail section (specifically the track) "rests" in this cup when the gate is fully closed, providing additional stability and support.

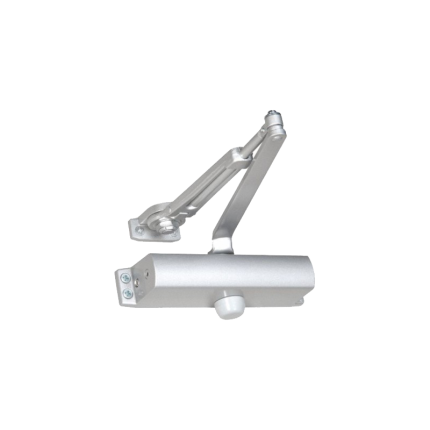

- Receiver Post / Gate Catch: A post or latching mechanism at the opposite end of the gate opening. When the gate is fully closed, it engages with this post to secure the gate in the closed position. This is often where a lock or the gate operator's arm connects.

- Support Wheels / Final Wheels: Sometimes, a small support wheel is mounted on the ground or a low post at the far end of the gate opening to provide extra support to the gate's leading edge when it's fully closed, especially for very long or heavy gates.

- Anchoring and Installation Accessories:

- Foundation Plates/Anchor Bolts: Heavy-duty plates and bolts used to securely anchor the cantilever carriages to concrete foundations. The stability of the entire system relies on robust anchoring.

- Tension Bars (less common in modern designs): Historically used for minor adjustments to gate alignment or sag, though modern systems are often designed to minimize this need.

Advantages of Cantilever Hardware:

- No Ground Track: This is the primary advantage. Eliminates the need for a track embedded in the driveway, which means:

- No debris accumulation (leaves, dirt, snow, ice) obstructing movement.

- Smoother operation on uneven driveways.

- Less maintenance in terms of track cleaning.

- No tripping hazard or wear on vehicles crossing a ground track.

- Durability and Low Maintenance: Because the main rolling components (carriages) are elevated and enclosed within the track, they are less exposed to dirt and weather, leading to longer life and less frequent maintenance.

- High Security: Cantilever gates are inherently very secure as they are difficult to lift or derail.

- Aesthetics: The absence of a ground track can contribute to a cleaner, more streamlined look for the driveway entrance.

- Suitable for High-Traffic Areas: Their robust design makes them ideal for commercial, industrial, or busy residential applications.

Suppliers in Surrey, British Columbia, Canada:

For purchasing cantilever sliding gate hardware in Surrey, BC, you would typically look for:

- Gate Automation and Supply Companies: Businesses specializing in automatic gates will carry a full range of cantilever hardware. Examples include Royal Gates (Royal Electronic Technology Center Co.), presence in the Metro Vancouver area, including Surrey.

- Fencing and Gate Fabricators: Many companies that custom-fabricate gates will also supply or install the necessary hardware.

- Industrial Hardware Suppliers: Larger industrial suppliers may stock components, though specialized gate companies will offer more comprehensive systems.

- Online Retailers: Many online suppliers ship to Canada, offering a wide variety of components from different manufacturers.

When considering cantilever gate hardware, it's crucial to select components that match the weight, length, and usage frequency of your gate to ensure long-term, reliable operation.

Reviews

There are no reviews yet.