Ship or pick up from our office.

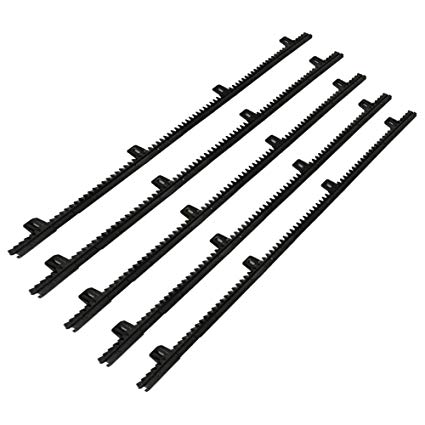

Sliding Gate V-Track

NOTE: For 25 ft sliding gate V-Track, please do not make an online order.

Because of the limit of the shipping length and weight, we have to cut the full length of the product (25') to 2 x (12'-6") for pick-up from our store OR 4 x (6'-3") to send by Canada Post.

If your order requires cutting services, additional costs will apply.

To create an order for sliding gate V-Track, please send your request with the shipping address, postal code, and the length of your inquiry in the note.

You will receive a quotation with the shipping costs within a maximum of one business day.

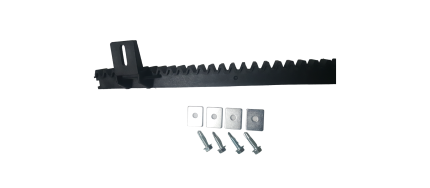

A sliding gate V-track is a specific type of ground track that a sliding gate rolls on, utilizing wheels with a complementary V-shaped groove.

This system is one of the most common ways to implement a sliding driveway gate, especially for residential and light commercial applications.

Here's a breakdown:

Purpose:

The sliding gate V-track as the linear guide and support for the entire sliding gate. It ensures that the gate moves in a straight line, smoothly, and without wobbling or derailing as it opens and closes.

It's an integral part of a "rolling gate" system, where the gate literally rolls on the ground.

Key Characteristics and Components:

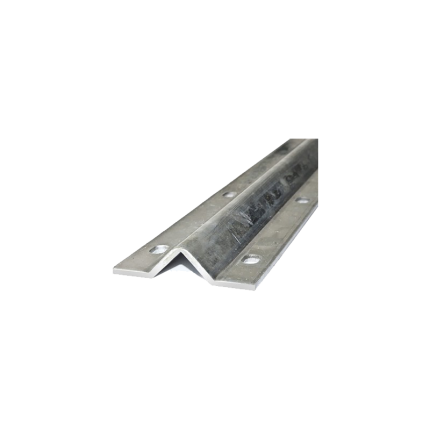

- V-Shape Profile: The most defining feature. The track has an inverted V-shape or a 90-degree angle (like an angle iron) with a slightly rounded top. This V-shape mates perfectly with the V-groove wheels attached to the bottom of the gate.

- Materials:

- Galvanized Steel (Most Common): Highly durable, strong, and resistant to corrosion due to the galvanization process. It can handle heavy gates and high traffic volumes. Sections are typically joined together to form the required length.

- Aluminum: Lighter weight and excellent corrosion resistance. Often used for lighter gates or in environments where rust is a major concern (like coastal areas).

- Installation:

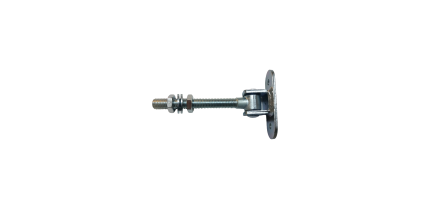

- Bolt-Down: The V-track is typically designed to be bolted securely to a concrete driveway or foundation. It has pre-drilled holes for anchor bolts. This allows for easier installation on existing concrete and simpler replacement if a section gets damaged.

- Embeddable (Less Common for DIY): Some V-tracks are designed to be embedded directly into wet concrete during construction.

- Level and Straight: Crucially, the V-track must be installed perfectly level and straight along the entire travel path of the gate to ensure smooth and consistent operation. Any dips, humps, or curves will cause issues with the gate's movement and can put undue strain on the gate operator and wheels.

- Lengths: Sliding gate V-tracks are sold in sections (e.g., 6 feet, 10 feet, 2.4 meters, 3 meters). Multiple sections are joined together using connection pins or by welding to achieve the total required length, which should be at least twice the width of the gate opening to allow the gate to fully retract.

- Complementary Hardware:

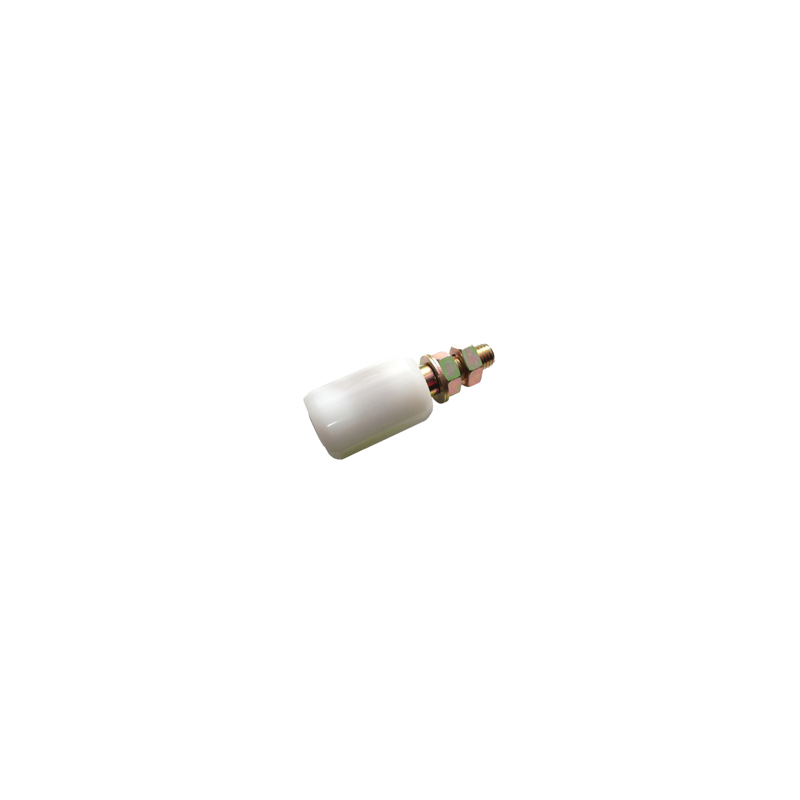

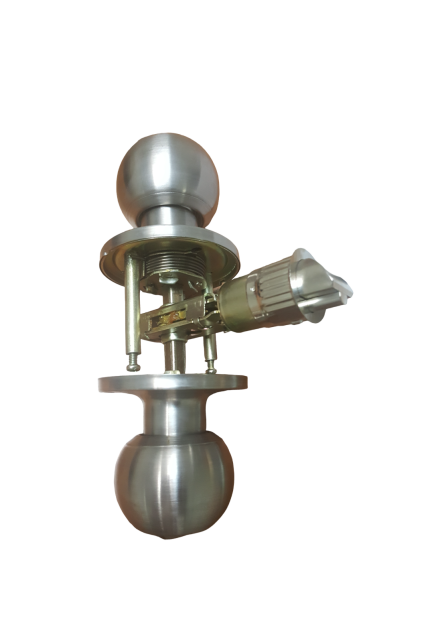

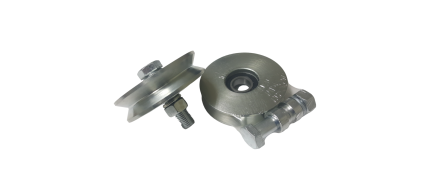

- V-Groove Wheels: These are essential and roll directly on top of the V-track. As discussed previously, they have a V-shaped groove that fits snugly into the track.

- Guide Rollers/Posts: Used at the top of the gate to keep it upright and prevent tipping.

- Gate Stops: Installed at the ends of the track to prevent the gate from over-traveling.

Advantages of V-Track Systems:

- Stability: The sliding gate V-track V-groove design provides excellent lateral stability, keeping the gate aligned and preventing it from wobbling.

- Load Capacity: Due to the direct ground support and robust V-track/wheel combination, these systems can handle very heavy and long gates.

- Simple Mechanical Principle: The system is straightforward, making it reliable.

Disadvantages/Considerations (especially in Vancouver, BC):

- Debris Accumulation: The main drawback is that the V-track, being on the ground, is susceptible to collecting dirt, leaves, gravel, snow, and ice. This debris can obstruct the gate's movement, cause wear on the wheels, and may even lead to derailment or damage to the gate opener. Regular cleaning of the track is essential, especially during winter months in Canada.

- Driveway Disruption: Installing a sliding gate V-track requires modifying the driveway surface, often by bolting it down or embedding it in concrete, which creates a slight raised profile.

- Water Drainage: Proper drainage around the track is important to prevent water pooling.

In summary, a sliding gate V-track is the foundation of a ground-rolling sliding gate system, providing the precise guide and support for the gate's V-groove wheels. When considering one for a property in Surrey, BC, it's crucial to factor in the need for regular track maintenance due to local weather conditions.

Reviews

There are no reviews yet.