hardware

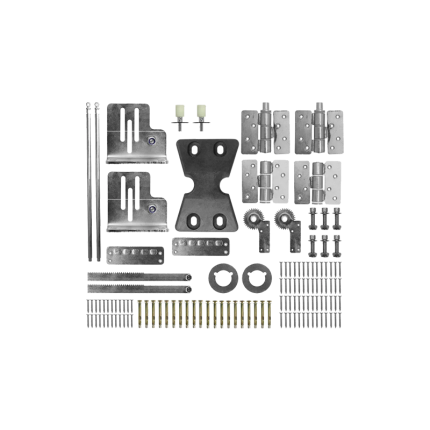

Bi-Folding Gate Hardware

Ship or pick up from our office.

Bi-Folding Gate Hardware

Bi-folding gate hardware refers to the mechanical components and accessories used to construct and operate gates that fold in half when opening, allowing for more efficient use of space.These components include hinges, rollers, pivots, guides, and other necessary parts that enable the gate to fold and unfold smoothly.

Key Components and Features:

-

Hinges:These are crucial for the folding action, connecting the gate leaves and allowing them to pivot.

-

Rollers and Guides:These components ensure smooth and stable movement of the gate along a track or within a frame.

-

Drop Bolts:These secure the gate in the open or closed position, providing stability and preventing unwanted movement.

-

Handles:These are used to manually operate the gate.

-

Specialized Mechanisms:Some systems utilize geared hinges or other mechanisms to ensure smooth and reliable operation, especially for larger gates.

Benefits of Bi-folding Gates:

-

Space Saving:Bi-folding gates require less space to open compared to traditional swinging gates, making them ideal for areas with limited space.

-

Versatility:They can be used with gate automation systems and are suitable for various gate sizes and configurations.

-

Enhanced Accessibility:Bi-folding gates provide easy access to enclosed spaces without obstructing parking or other areas.

-

Improved Aesthetics:They can be designed with various styles and finishes to complement the overall aesthetic of the property.

-

Cost-Effective:Bi-folding gates can be more cost-effective to automate than traditional double swing gates as they require fewer operators.

Applications:

- Residential driveways where space is limited.

- Commercial and industrial properties requiring secure access.

- Areas with challenging terrain, such as those with gravel surfaces.

- Condominiums and other multi-unit dwellings.

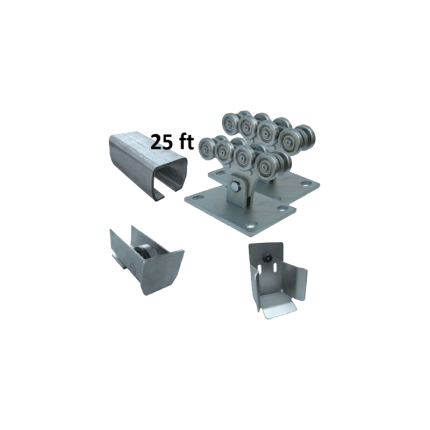

Cantilever Sliding Gate Hardware

Ship or pick up from our office.

Cantilever Sliding Gate Hardware

Cantilever sliding gate hardware refers to the specialized components that allow a gate to slide open and close without needing a track on the ground. Instead, the gate is supported and guided from above and to the side by a system of rollers and channels. Here's a breakdown of the essential components that make up cantilever sliding gate hardware:- Cantilever Track (or Rail):

- This is the most distinctive part. It's a heavy-duty, usually C-shaped (or sometimes a more complex extruded profile) channel that's securely attached to the bottom (or sometimes top) of the gate frame itself.

- The track is extended beyond the main gate opening to form the "tail" or counterbalance section, which supports the gate when it's fully open.

- Materials: Commonly made from galvanized steel for strength and corrosion resistance, or aluminum for lighter weight and superior corrosion resistance (as discussed previously).

- Cantilever Carriages (or Trolleys/Rollers):

- These are the critical load-bearing components. They consist of a sturdy base plate with multiple wheels (often 5, 8, or more) arranged in a specific configuration.

- The wheels are made from durable materials like steel (often machined or cast) or high-impact nylon, and typically feature sealed bearings for smooth, maintenance-free operation.

- The cantilever track fits over these carriages, with the wheels rolling inside the track's channel.

- Two (or more for very long/heavy gates) carriages are typically mounted on strong concrete foundation posts, positioned outside the gate opening. These posts support the entire weight of the gate.

- Guide Rollers/Plates (Upper Guides):

- These are smaller rollers or plates mounted on a separate guide post (or posts) on the same side as the cantilever carriages.

- Their purpose is to keep the gate upright and prevent it from tipping over as it moves. They typically engage with the top rail of the gate.

- Made from nylon, steel, or a combination, often with adjustable brackets.

- End Cups / Receiver Posts / Gate Catches:

- End Cup (or End Stop): A cup or bracket mounted on the support posts at the fully closed position. The end of the gate's tail section (specifically the track) "rests" in this cup when the gate is fully closed, providing additional stability and support.

- Receiver Post / Gate Catch: A post or latching mechanism at the opposite end of the gate opening. When the gate is fully closed, it engages with this post to secure the gate in the closed position. This is often where a lock or the gate operator's arm connects.

- Support Wheels / Final Wheels: Sometimes, a small support wheel is mounted on the ground or a low post at the far end of the gate opening to provide extra support to the gate's leading edge when it's fully closed, especially for very long or heavy gates.

- Anchoring and Installation Accessories:

- Foundation Plates/Anchor Bolts: Heavy-duty plates and bolts used to securely anchor the cantilever carriages to concrete foundations. The stability of the entire system relies on robust anchoring.

- Tension Bars (less common in modern designs): Historically used for minor adjustments to gate alignment or sag, though modern systems are often designed to minimize this need.

- No Ground Track: This is the primary advantage. Eliminates the need for a track embedded in the driveway, which means:

- No debris accumulation (leaves, dirt, snow, ice) obstructing movement.

- Smoother operation on uneven driveways.

- Less maintenance in terms of track cleaning.

- No tripping hazard or wear on vehicles crossing a ground track.

- Durability and Low Maintenance: Because the main rolling components (carriages) are elevated and enclosed within the track, they are less exposed to dirt and weather, leading to longer life and less frequent maintenance.

- High Security: Cantilever gates are inherently very secure as they are difficult to lift or derail.

- Aesthetics: The absence of a ground track can contribute to a cleaner, more streamlined look for the driveway entrance.

- Suitable for High-Traffic Areas: Their robust design makes them ideal for commercial, industrial, or busy residential applications.

- Gate Automation and Supply Companies: Businesses specializing in automatic gates will carry a full range of cantilever hardware. Examples include Royal Gates (Royal Electronic Technology Center Co.), presence in the Metro Vancouver area, including Surrey.

- Fencing and Gate Fabricators: Many companies that custom-fabricate gates will also supply or install the necessary hardware.

- Industrial Hardware Suppliers: Larger industrial suppliers may stock components, though specialized gate companies will offer more comprehensive systems.

- Online Retailers: Many online suppliers ship to Canada, offering a wide variety of components from different manufacturers.

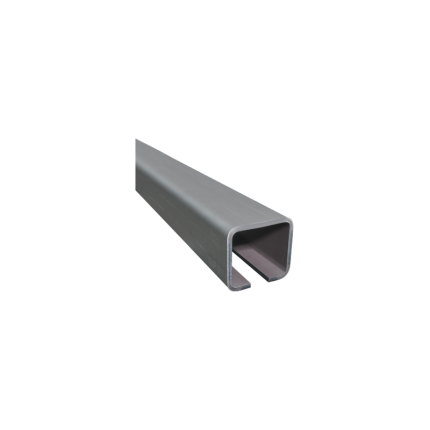

Cantilever sliding gate track

Ship or pick up from our office.

Cantilever sliding gate track

A cantilever sliding gate track with aluminum material is a specific type of gate system designed for smooth, overhead operation without needing a track embedded in the ground. Here's a breakdown: Understanding Cantilever Gates First: Traditional sliding gates often have wheels that roll on a track set into the driveway or ground. Cantilever gates are different. They "cantilever" or hang over the opening, supported by a set of rollers or carriages mounted on posts outside the gate opening. The gate itself has a longer "tail" section that acts as a counterbalance, allowing the main gate panel to span the opening without touching the ground. Key Components of a Cantilever System:- Gate Panel: The main part of the gate that opens and closes.

- Tail Section: An extended portion of the gate that balances the main panel and runs through the support posts.

- Track (often "C-channel" or similar profile): This is the crucial part that the carriages or rollers run inside. It's typically integrated into the gate frame itself, usually along the bottom or sometimes the top of the gate structure.

- Carriages/Rollers: These are assemblies with wheels (often nylon or sealed bearings) that are securely mounted to the support posts. The gate's track slides over these carriages, allowing the gate to move.

- Guide Rollers/Posts: Additional rollers or posts that keep the gate upright and guide its movement at the top.

- Receiver Post: Where the gate latches or receives when fully closed.

- Lightweight: Aluminum is much lighter than steel, which reduces the overall weight of the gate. This makes it easier for the gate operator (motor) to move the gate, potentially extending the operator's lifespan and reducing energy consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is a major benefit, especially in areas with high humidity, rain, or salt, like coastal regions or places with harsh winters (relevant for Surrey, BC). Steel tracks often need galvanization or regular painting to prevent rust.

- Durability: Despite being lightweight, aluminum alloys (like 6061-T6 or 6005-T5, commonly used in gates) are very strong and durable, capable of handling significant loads and regular use.

- Low Maintenance: Due to its corrosion resistance, aluminum tracks require very little maintenance in terms of rust prevention. General cleaning to remove debris is still recommended.

- Aesthetics: Aluminum can be finished in various ways, including powder coating in different colors, or left with a natural mill finish. This allows for greater design flexibility to match the property's aesthetics.

- Ease of Fabrication and Installation: Aluminum is easier to cut, drill, and weld than steel, which can sometimes simplify the manufacturing and installation process. Many aluminum cantilever gate systems are modular or "knock-down," meaning they can be assembled on-site, which is beneficial for large or tall gates that are difficult to transport.

- No Ground Track: Eliminates the need for a track on the ground, which means:

- No accumulation of debris (leaves, dirt, snow, ice) that can obstruct the gate's movement.

- Smoother operation, even on uneven driveways.

- Reduced wear and tear on the gate's wheels/rollers, as they are enclosed within the track.

- No tripping hazard from a ground track.

- High Security: Cantilever gates are generally more secure than swing gates as they are harder to force open.

- Space Saving: They slide parallel to the fence line, requiring less clear space than swing gates.

- Good for High Traffic: Their robust design and often lower maintenance make them suitable for frequent use.

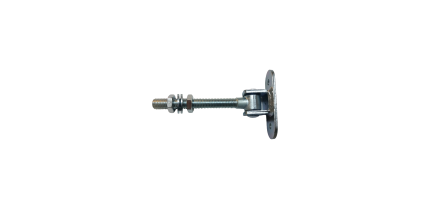

Gate adjustable hinges

Ship or pick up from our office.

Gate adjustable hinges

*Steel material *Heavy-duty hinge *5-1/2” Length (Total 7-1/2”) x 4-1/2” Width *Bolt thickness: 3⁄4” Gate adjustable hinges are a type of hinge designed to allow for precise adjustments to a gate's position and alignment even after it has been installed. Unlike traditional fixed hinges, which offer little to no post-installation flexibility, adjustable hinges provide the ability to fine-tune the gate's fit. This feature is particularly beneficial for gates that may sag over time due to their weight, ground settling, or weather changes. Why are Adjustable Hinges Important? Adjustable hinges solve common problems associated with gate installation and long-term use. Without them, realigning a sagging or misaligned gate often requires removing the gate, cutting, re-welding, and repainting the hinges, which is a time-consuming and labor-intensive process. With adjustable hinges, these adjustments can typically be made with simple tools like an Allen key or an adjustable wrench. Key Features and Adjustments Adjustable hinges offer various levels of adjustment, which can include:- In/Out Adjustment: This is the most common adjustment, allowing the gate to be moved closer to or further away from the post. This helps eliminate gaps or prevent the gate from rubbing against the frame.

- Up/Down Adjustment: This allows for vertical alignment, which is crucial for ensuring the gate clears the ground and for aligning the gate's lock with its strike plate, especially for double swing gates.

- Left/Right Adjustment: Some advanced models offer lateral adjustment, providing ultimate flexibility in positioning the gate along its width. This can also help in adjusting the gate's tilt.

- Adjustable Eye Bolts: These are threaded components that allow vertical and horizontal adjustment, typically used with hook-on plates or gate pins.

- Adjustable Band and Gudgeon Hinges: Similar to traditional band and gudgeon hinges, but with a threaded bolt and nuts for adjustment.

- Weld-on Adjustable Hinges: Designed to be welded directly to metal gates and posts, offering strong support and adjustability.

- Bolt-on Adjustable Hinges: These are bolted to the gate and post, making them suitable for various gate materials.

- Barrel Hinges (Adjustable): Often featuring a set screw for up/down adjustments, suitable for heavier loads and offering a robust design.

- Adjustable Self-Closing Hinges: Some adjustable hinges also incorporate a self-closing mechanism, which is ideal for security gates or areas where the gate needs to close automatically.

- Ease of Installation and Adjustment: They simplify the initial installation process by allowing for fine-tuning without needing to perfectly align everything from the start. Subsequent adjustments due to settling or wear are also quick and easy.

- Longevity: By maintaining proper alignment, adjustable hinges reduce wear and tear on both the gate and the hinges themselves, extending their lifespan.

- Enhanced Security: Proper alignment minimizes gaps around the gate, making it harder for unauthorized entry.

- Versatility: They are available in various sizes and load capacities, suitable for everything from lightweight garden gates to heavy-duty industrial gates.

- Reduced Maintenance Costs: The ability to easily adjust the gate's position can significantly reduce the need for costly repairs or re-installations.

- Improved Aesthetics: Ensures the gate maintains a straight and professional appearance, avoiding unsightly sagging or misalignment.

- Steel: Strong and ideal for heavy-duty gates, often galvanized or treated to prevent rust.

- Stainless Steel: Offers excellent corrosion resistance, making it perfect for outdoor and high-moisture environments.

- Zinc-plated Steel: Provides a good balance of durability, cost-effectiveness, and rust protection.

- Brass: Less strong than steel but used for decorative purposes due to its aesthetic appeal.

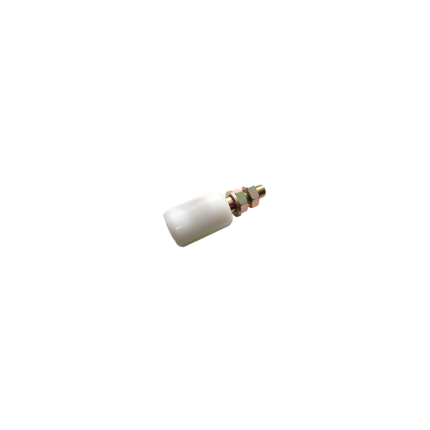

Key selector -Key Automation EGS101

Ship or pick up from our office.

Key selector -Key Automation EGS101

The EGS101 is a gate/door opener key selector manufactured by KeyAutomation. It's designed for high-security residential and commercial properties and allows manual operation of automatic gates or doors using a physical key, according to KeyAutomation.A key selector for gates is a physical switch, often a key-operated switch, that allows manual operation of an automatic gate or door.

It's a security feature and backup system for situations where automated control is unavailable or undesirable.

TECHNICAL FEATURES

| Voltage | Vdc | Max 48 |

| Degree of protection | IP | 55 |

| Dimensions (L - D - H) | mm | 79 - 23 - 79 |

| Item | kg | 0,335 |

| Minimum operating temperature | °C | -20 |

| Max operating temperature | °C | +55 |

A key selector for door openers is a switch that allows you to operate an automated door or gate using a physical key, often as an alternative or backup to other access methods like remote controls or keypads.

These switches are commonly used in situations where you need to control access to a gate, garage door, or other automated barrier.

-

Function:Key selectors are designed to activate the door or gate opener's motor by completing an electrical circuit when the key is turned.

-

Mechanism:They typically involve a key cylinder that, when turned, activates a set of electrical contacts.

-

Applications:They are used in various settings, including residential, commercial, and industrial applications, such as garage doors, gates, and automatic doors.

-

Features:Some key selectors offer multiple functions, like automatic, lock, exit, and hold-open modes.

-

Types:They can be found as jamb key switches for garage doors or as more sophisticated selector switches for automatic doors with multiple functions.

Keypad Access Control K110V2000

Keypad Access Control K110V2000

*Waterproof Version *EM - RFID card/tag reader *Finger Touch *Backlight *DC 12 V *1000 Users *Doorbell button *Rain Shield Cover IncludedThe Keypad Access Control K110V2000 is a standalone access control system designed for single-door access, typically used for residential or small-to-medium commercial buildings.

It allows users to unlock the door using either a proximity card, a PIN code, or a combination of both.

Here's a more detailed breakdown:

Key Features:

- Multiple User Capacity: It can support up to 1000 users.

- Multiple Access Methods: Users can unlock the door using RFID cards, PIN codes, or both.

- Standalone Operation: It functions independently, without needing to be connected to a central computer.

- Wiegand Input/Output: It can connect to an external card reader (Wiegand 26 input) and a controller (Wiegand 26 output).

- Tamper Alarm: Includes a tamper alarm for added security.

- Backlit Keypad: The keypad is backlit, making it easier to use in low-light conditions.

- Short Circuit Protection: The output is automatically turned off if there's a short circuit in the electric lock or alarm output.

- Waterproof: Some models, like the V2000-C, are waterproof, making them suitable for outdoor use.

- Easy Installation and Programming: The system is designed for straightforward installation and programming.

- Doorbell Input: Some models include a doorbell input.

- Adjustable Settings: Features like door output time, alarm time, and door open time can be adjusted.

Applications:

- Residential Buildings: Ideal for controlling access to apartments or individual homes.

- Small to Medium Businesses: Suitable for offices, shops, and other commercial spaces.

- Warehouses and Factories: Can be used to manage access to secure areas.

- Other Applications: Laboratories, banks, and even prisons.

Metal Case Diode Bridge KBPC5010

Ship or pick up from our office.

Metal Case Diode Bridge KBPC5010

The Metal Case Diode Bridge KBPC5010 is a specific type of bridge rectifier, a crucial electronic component used to convert alternating current (AC) into direct current (DC). It is widely employed in various power supply applications. Here's a breakdown of its key features and what each part of its name signifies: What is a Bridge Rectifier? A bridge rectifier is a circuit of four (or more) diodes in a specific configuration that allows for full-wave rectification. This means it efficiently converts both the positive and negative half-cycles of an AC input into a pulsating DC output. Compared to simpler half-wave rectifiers, bridge rectifiers are more efficient and provide a smoother DC output. KBPC5010 Explained- KBPC: This is typically a series designation for a family of single-phase bridge rectifiers with specific package styles.

- 50: This number indicates the maximum average forward rectified current (Io) the device can handle, which in this case is 50 Amperes (A). This high current rating makes it suitable for demanding applications.

- 10: This number typically refers to the voltage class, often indicating a maximum repetitive peak reverse voltage (VRRM) of 1000 Volts (V) (where '10' often means 10 x 100V). This high voltage rating allows it to handle substantial AC input voltages.

- Conversion: Converts single-phase AC to pulsating DC.

- Current Rating: Up to 50 Amperes (A) average forward current.

- Voltage Rating: Up to 1000 Volts (V) repetitive peak reverse voltage.

- Surge Current Capability: Often capable of handling high non-repetitive surge currents (e.g., 400A or 450A for a short duration), which is crucial for handling initial power-on transients.

- Low Forward Voltage Drop: Minimizes power loss and improves efficiency.

- High Reliability: Designed for robust performance in various environments.

- Mounting: Typically features through-hole mounting with a screw hole for chassis or heatsink mounting.

- Terminals: Often uses 0.25" (6.35 mm) Faston terminals for easy connection. Some variants (like KBPC5010W) might have wire leads.

- Operating Temperature: Wide operating junction temperature range, often from -40°C to +150°C.

- Power supplies: As a core component to rectify AC mains voltage into DC for electronic devices.

- Battery chargers: Converting AC power to DC for charging batteries.

- Motor control circuits: Providing DC power for electric motors.

- Industrial control systems: Used in various industrial applications requiring AC-to-DC conversion.

- Input rectifiers for variable frequency drives (VFDs).

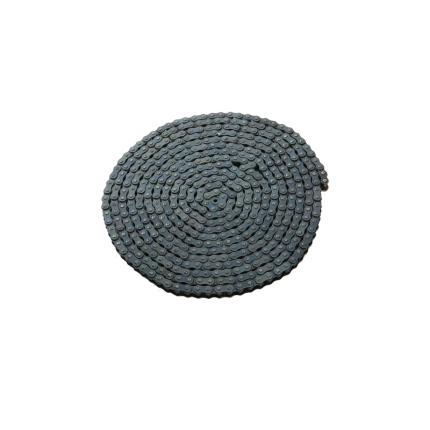

Sliding gate operator chain

Ship or pick up from our office.

Sliding gate operator chain

*Length: 10 FeetA sliding gate operator chain is a specialized type of chain used in automated sliding gates to connect the gate to the motor, enabling the gate to open and close smoothly.

It acts as the mechanical link between the motor's drive system and the gate, facilitating the gate's horizontal movement along a track.

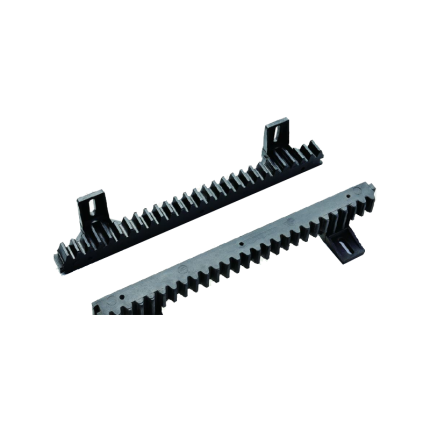

Sliding gate operator gear rack -SLGR2

Ship or pick up from our office.

Sliding gate operator gear rack -SLGR2

The Sliding Gate Operator Gear Rack SLGR2 is a specific type of toothed bar used in conjunction with a sliding gate operator (motor) to convert its rotational power into the linear motion needed to open and close a sliding gate. Let's break down what SLGR2 likely refers to and its characteristics: Function of a Gear Rack:- Linear Motion: The Sliding Gate Operator Gear Rack SLGR2 is essentially a straight "rack" of teeth that meshes with a small circular gear called a pinion, which is attached to the shaft of the sliding gate operator's motor.

- Power Transmission: As the pinion spins, its teeth engage with the teeth of the gear rack, pushing or pulling the gate horizontally along its track. This is how the motor physically moves the gate.

- Length: The Sliding Gate Operator Gear Rack SLGR2 is specified as being 340 mm (millimetres) in length. This is a relatively short segment. Sliding gates often require multiple sections of gear rack to be joined together to span the entire length of the gate, as most gates are much longer than 340mm.

- Mounting Holes: It has "2 Holes". These holes are pre-drilled for easy attachment to the bottom frame of the sliding gate using screws or bolts.

- Material: While the exact material for this specific SLGR2 is not explicitly stated in all listings, gear racks are commonly made from:

- Steel (most common): Offers high strength, durability, and resistance to wear, making it suitable for heavy gates and high-traffic applications. Often galvanized or treated for corrosion resistance.

- Nylon with a Steel Core: A popular alternative. The nylon exterior provides quieter operation and good corrosion resistance, while the internal steel core offers the necessary strength and stability for the gate's weight and movement. This is a good balance of properties.

- Less commonly, other plastics or stainless steel are used for specific applications.

- "Module": While not explicitly stated for SLGR2, gear racks (and their mating pinions) adhere to a "module" standard (e.g., Module 2, Module 4). The module defines the size of the teeth and the spacing between them, ensuring that the gear rack properly meshes with the pinion gear of the specific sliding gate operator it's intended for. The SLGR2 would have a specific module that matches the operators sold by Royal Gate.

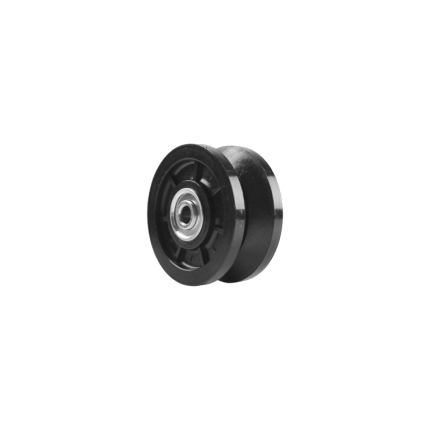

Sliding gate support roller

Ship or pick up from our office.

Sliding gate support roller

Sliding gate roller guides are essential components of sliding gates that facilitate smooth and controlled movement along a track or rail.

They help the gate stay aligned, preventing it from wobbling or coming off the track during operation. These guides are typically comprised of a bracket (often L-shaped) and one or more rollers, often made of nylon, that minimize friction and ensure quiet, efficient gate movement.

Key functions of sliding gate roller guides:

-

Smooth & Stable Movement:They ensure the gate slides smoothly along the track, preventing jerky movements and noise.

-

Alignment & Stability:They keep the gate aligned with the track, preventing it from wobbling or falling off.

-

Reduced Friction:The rollers minimize friction between the gate and the track, improving the gate's efficiency and lifespan.

-

Enhanced Durability:By reducing friction and stress on the gate and its components, they contribute to the longevity of the entire system.

Types of Sliding Gate Roller Guides:

-

L-Shaped Bracket with Rollers:This is a common type, featuring an L-shaped bracket that can be mounted on a post and nylon rollers that guide the gate.

-

Cantilever Gate Rollers:Specifically designed for cantilever gates (those that don't require a bottom track), these rollers provide support and smooth movement.

-

Adjustable Rollers:Some guides allow for horizontal adjustment of the roller position to accommodate different gate widths.

-

Flat Mount Wheels:Used when there's no need for a wheel cutout, these screw directly onto the bottom rail of the gate.

Materials and Construction:

-

Rollers:Typically made of nylon or other durable materials that can withstand wear and tear.

-

Brackets:Often made of steel (galvanized or stainless steel) for strength and durability.

Applications:

Sliding driveway gates, Security gates, Garden gates, Barn doors, Garage doors, Sheds, and Storage spaces.

In essence, sliding gate roller guides are critical for the proper functioning and longevity of sliding gates, ensuring smooth, reliable, and quiet operation.